Electrochromatography device

A technology of electrochromatography and chromatographic separation, which is used in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of bubbles, difficult filling process, and shorten the service life of analyzers, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

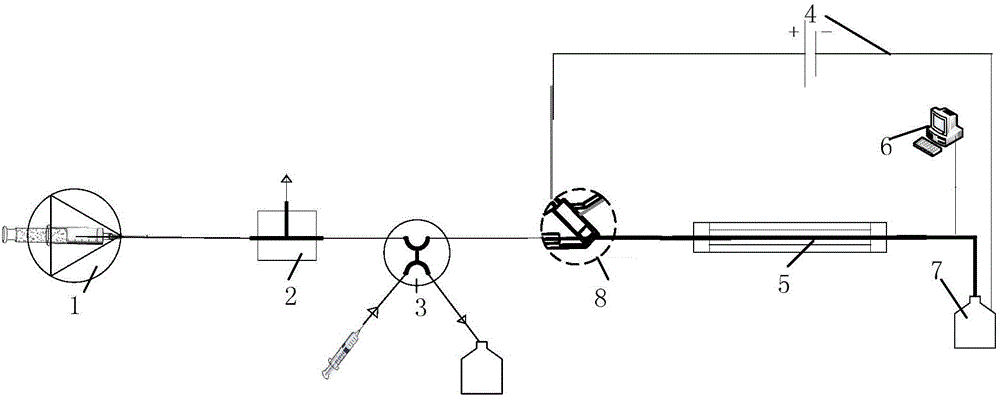

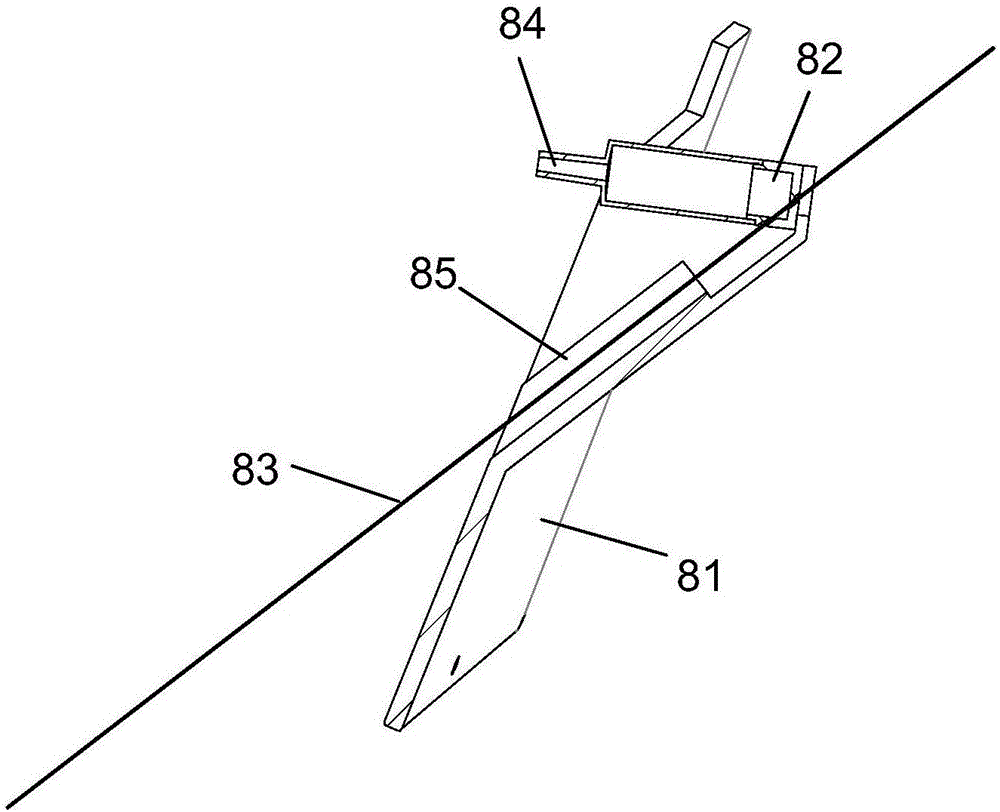

[0031] The electrochromatographic device of this embodiment includes an infusion system located on the liquid inlet pipeline. The liquid outlet of the microflow pump passes through the split three-way distributor successively, and then passes through the nanoliter quantitative sampling valve, the electric isolation device, and the open pipe. After the electrochromatographic column and the detector, it is connected to the waste liquid pool; the liquid outlet of the microflow pump and the inlet of the quantitative sampling valve are connected by a split tee; the outlet of the quantitative sampling valve and the inlet of the open-tube column Connect an electrical isolation device; the open-tube chromatographic column is in the temperature control system, and there is a window connected to the detector on the column body, and the detector is connected to the data processing system; finally, the outlet of the open-tube column is connected to the waste liquid pool, and the waste liqui...

Embodiment 2

[0042] An electrochromatographic device with the same structure as in Example 1 was used.

[0043] Preparations before analysis:

[0044] 1. Open the infusion system, take 1ml of phosphate solution containing 30% methanol, and adjust the flow rate to 2ul / min;

[0045] 2. Take a total length of 80cm (the length from the detection window to the outlet is 20cm), and a 75um inner diameter open-tube capillary chromatographic column (with a C18 reversed-phase stationary phase coating inside), and install it on the electrochromatographic device.

[0046] Separation analysis:

[0047] 1. Run the column thermostat and adjust the temperature to 15°C;

[0048] 2. Run the UV detector and adjust the detection wavelength to 220nm;

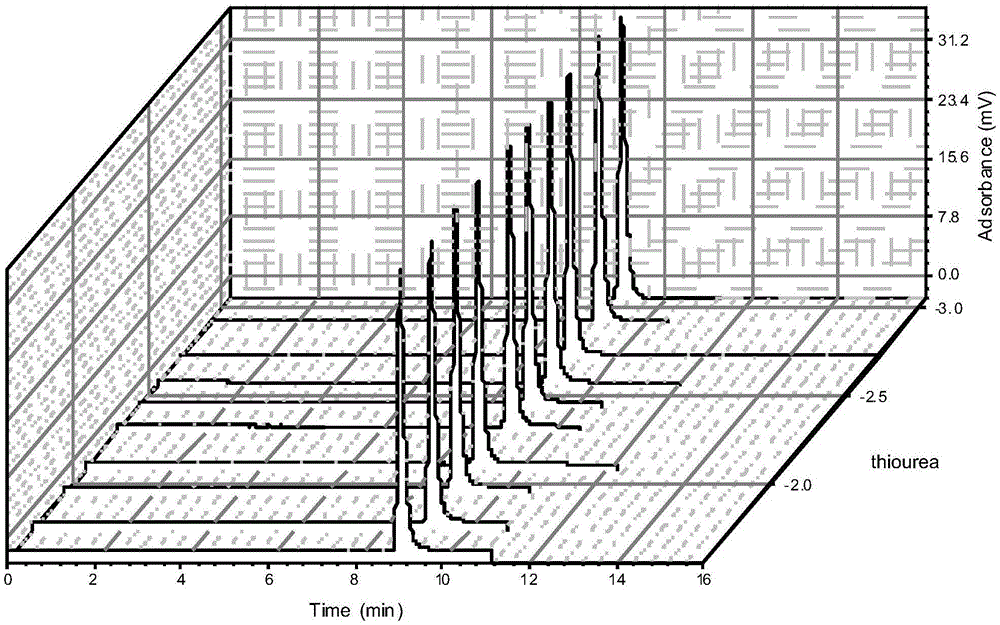

[0049] 3. After the system is stabilized, take 0.1mg / ml mixed sample of 3 kinds of neutral substances (thiourea, naphthalene, biphenyl) and inject it into the quantitative valve. Under the condition of no power supply, the sample can be separated within 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com