Apparatus and method of monitoring unidirectional force by means of liquid mixing color changing

A liquid mixing, unidirectional force technology, applied in the field of sensing, can solve the problems of difficult manufacturing, complex device structure, and inability to monitor remotely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Embodiment: Taking the anchor rod as an example, the implementation process of the present invention is set forth:

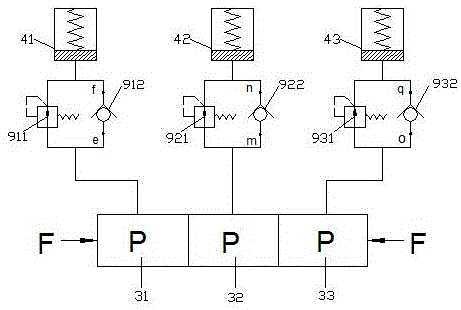

[0053] like Figure 1~4 As shown in the figure, a device for monitoring one-way force by using liquid mixing and discoloration, including a bearing mechanism, a hydraulic control valve group and a display mechanism; the bearing mechanism is located outside the anchor rod or bolt to be tested, the upper part is connected to the self-aligning ball pad, and the lower part is connected to the nut ;

[0054] The carrying mechanism includes a cylindrical carrier 6 and a pressure chamber 3. The carrier 6 is provided with upper, middle and lower annular pressure chambers 3 with the same volume. The annular pressure chambers 3 are respectively provided with liquids of different colors. , and the annular pressure chamber 3 is coaxial with the bearing body 6, the inside of the bearing body 6 is an anchor rod 7, and the inner ring of the bearing body 6 is a zigzag s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com