Method for preparing corrosion-resistant 410 stainless steel

A stainless steel, corrosion-resistant technology, applied in the pouring control of molten metal from the ladle, manufacturing tools, casting equipment, etc. Good mold performance, good machinability, good corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

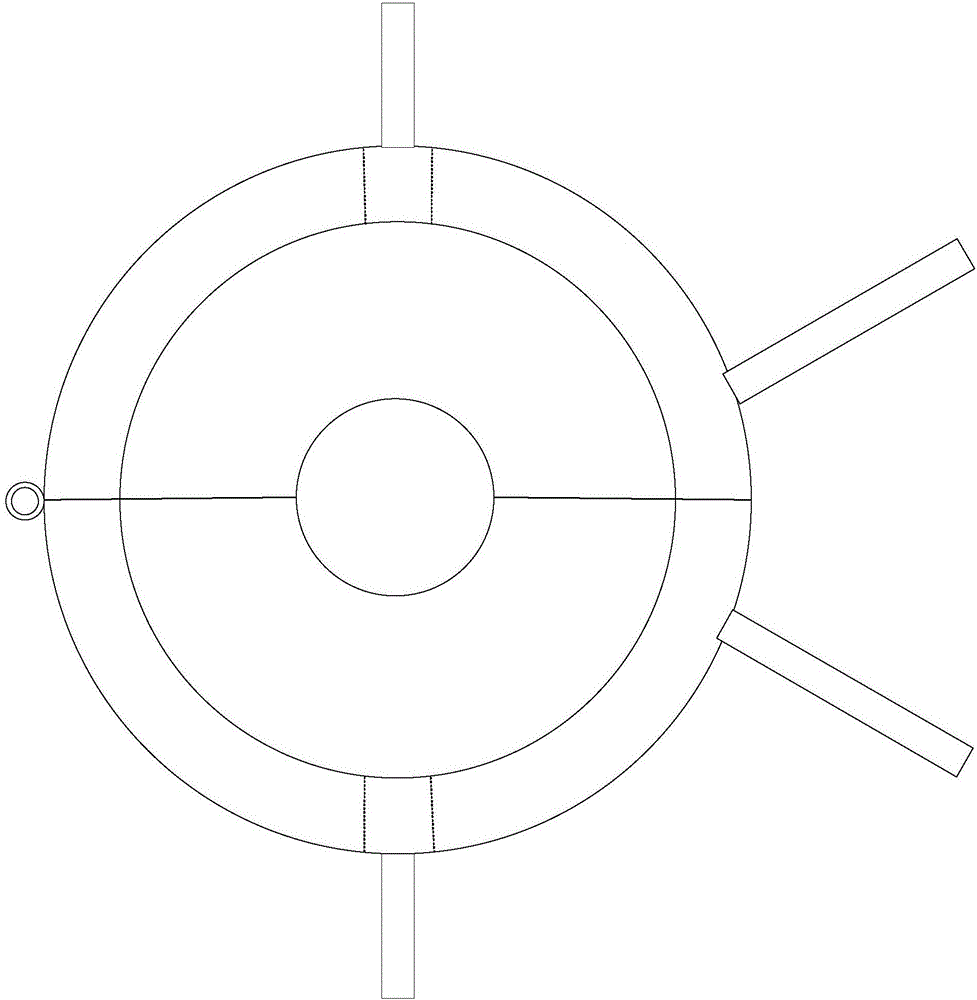

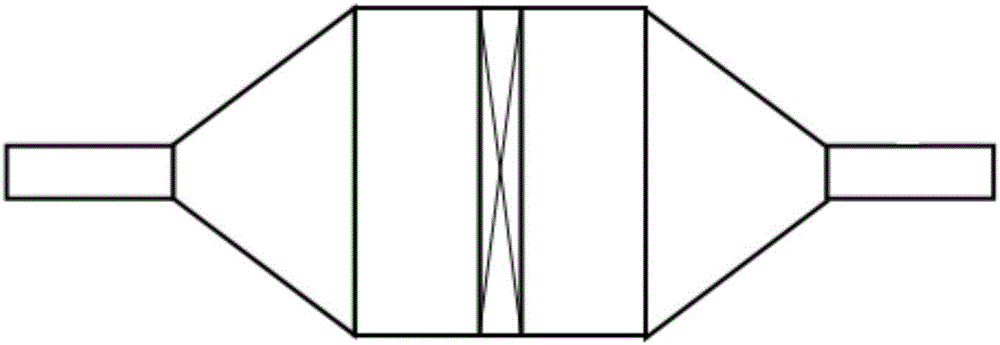

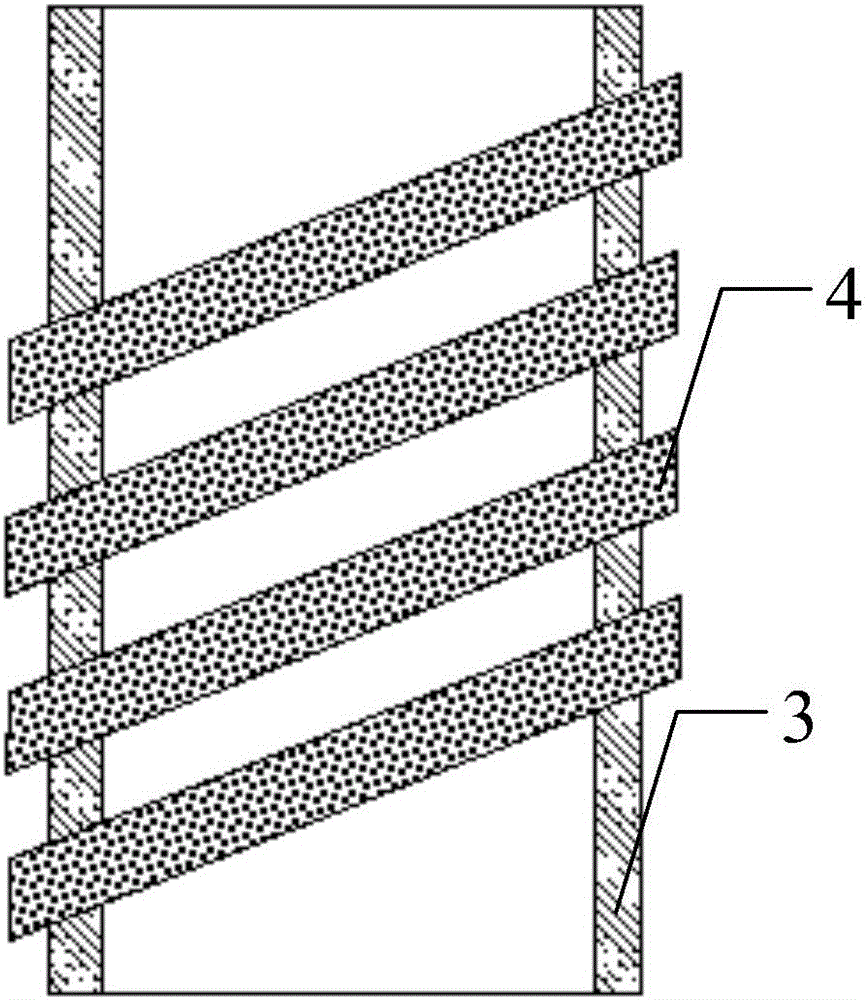

[0039] Electroslag remelting air hood assembly, see figure 1 , figure 2 and image 3 As shown, the annular sealing cover 1 is included, the inside of the annular sealing cover 1 is hollow and filled with heat insulating material, the inner side of the annular sealing cover 1 is provided with an opening, and the annular sealing cover 1 is provided with an additional Two through holes 12 are provided on the side of the tube 11 and the annular sealing cover 1 .

[0040] The annular sealing cover 1 comprises two semi-circular sealing covers with the same size and shape, one end of the two semi-circular sealing covers is hinged, and a handle is provided at the other end. Dividing the annular sealing cover into two semi-circular sealing covers facilitates the placement of the sealing cover. A sealing layer is arranged above the annular sealing cover 1 . The sealing layer is rock wool layer. Rock wool can act as a heat insulator and a seal at the same time.

[0041] The two th...

Embodiment 2

[0055] The preparation method of corrosion-resistant 410 stainless steel comprises the following steps:

[0056] (1) Molten steel making: heat the steel slag from the water-washed ball mill at 1520°C for 6 hours to make the steel slag turn into molten steel and boil;

[0057] (2) Primary refining: Refining in LF furnace for 20 minutes, testing every 10 minutes until the sulfur content is lower than 8‰;

[0058] (3) Secondary refining: In the VD furnace, pass through the argon gas to refine for 40 minutes until it does not boil;

[0059] (4) Mixing: Pass the product of step (3) into the smelting furnace, add trace elements, and continue smelting for 1 hour to obtain a smelting liquid; the ratio of the added weight of the trace elements to the total weight of the raw materials is: Cu 0.16%, Mg 1.16 %, Ti 0.06%, Sr 0.18%, Zr 0.28%, B 0.50%, V 0.54%, Zn 0.31%, Re 0.15%, Sn 0.42%, Pb 0.68%, Be 0.25%, Sc 0.21%, Li 0.53% , Ni 0.72%, La 0.03%;

[0060] (5) Pouring: pour the smeltin...

Embodiment 3

[0065] The preparation method of corrosion-resistant 410 stainless steel comprises the following steps:

[0066] (1) Molten steel making: heat the steel slag from the water-washed ball mill at 1530°C for 4 hours to make the steel slag turn into molten steel and boil;

[0067] (2) Primary refining: Refining in LF furnace for 40 minutes, testing once every 10 minutes until the sulfur content is lower than 8‰;

[0068] (3) Secondary refining: In the VD furnace, pass through the argon gas and refine for 20 minutes until it does not boil;

[0069] (4) Mixing: Pass the product of step (3) into the smelting furnace, add trace elements, and continue smelting for 2 hours to obtain a smelting solution; the ratio of the added weight of the trace elements to the total weight of the raw materials is: Cu 0.18%, Mg 1.18 %, Ti 0.08%, Sr0.16%, Zr 0.26%, B 0.46%, V 0.56%, Zn 0.35%, Re 0.18%, Sn 0.38%, Pb 0.66%, Be0.23%, Sc 0.23%, Li 0.55% %, Ni 0.76%, La 0.01%;

[0070] (5) Pouring: pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com