PC/ABS (polycarbonate/acrylonitrile butadiene styrene) alloy and preparation process thereof

A preparation process and alloy technology, which is applied in the field of PC/ABS alloy and its preparation process, can solve the problems that the mechanical properties and processing properties of PC/ABS alloy cannot be significantly improved, polybutadiene is difficult to be compatible, and the physical properties are reduced. , to achieve the effect of good fluidity, not easy to flow marks, and large melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

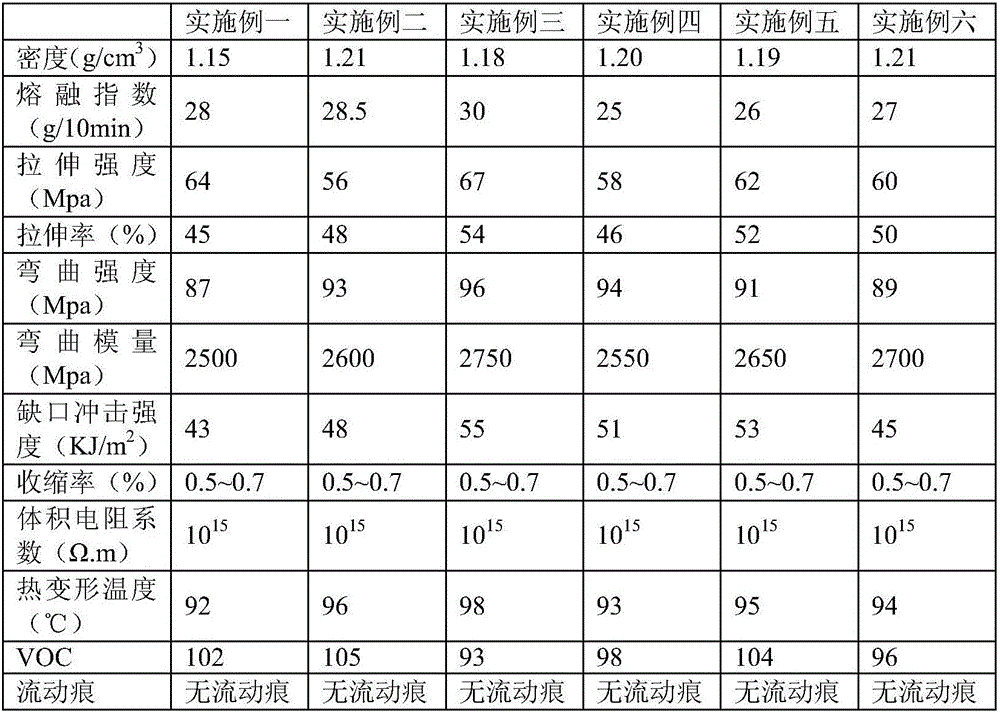

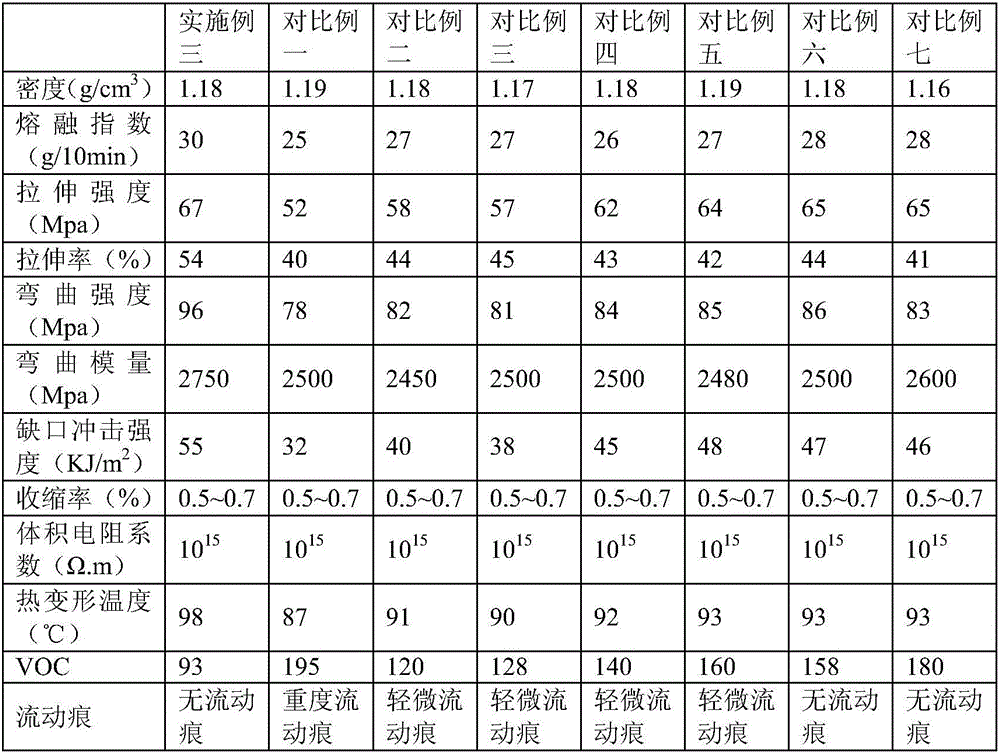

Examples

preparation example Construction

[0040] The preparation method of pomelo peel extract:

[0041] (1) Put the pomelo peel into an extraction tank after being crushed and mixed with absolute ethanol in a weight ratio of grapefruit peel: absolute ethanol = 1:1, heated to 50°C and then refluxed for 3 hours to collect the extract;

[0042] (3) Import the collected extract into a concentrator for concentration under reduced pressure at a temperature of 25°C and a vacuum of 1.0Mpa, and concentrate to 1 / 4 of the volume of the original extract;

[0043] (4) Set the rotating speed of the concentrated extract in a horizontal centrifuge as 4800r / min for centrifugal 3min;

[0044] (5) Filter and get the filtrate into the D101 macroporous resin column, the flow rate is 1.5BV / hr, wash the column with ethanol with a mass concentration of 70% until the effluent is clear, the time is 2h, collect the effluent from the macroporous resin column The clear, transparent, slightly mellow eluate, the collected eluate is 1 times the am...

Embodiment 1

[0050] (1) Dry PC at 120°C for 3.2 hours, and dry ABS at 50°C for 4 hours;

[0051] (2) Weigh 45 parts of PC, 45 parts of ABS, 5 parts of MBS, 5 parts of ABS-g-MAH, 4 parts of SMA, 1.2 parts of PET, 1 part of black masterbatch, 3 parts of adsorbent A, 4 parts of antibacterial agent, antibacterial Pour 0.2 parts of oxidant and 0.6 parts of chemical deodorant into a high-speed mixing tank, and the stirring speed is 330r / min;

[0052] (3) Add the material mixed in step (2) into the twin-screw extruder with an aspect ratio of 48:1. The temperature inside the barrel of the twin-screw extruder is: 220°C in the first zone, 240°C in the second zone, and 240°C in the third zone 240°C, 240°C in the fourth zone, 240°C in the fifth zone, 240°C in the sixth zone, 240°C in the seventh zone, 240°C in the eighth zone, 240°C at the head, and the speed of the twin-screw extruder is 330r / min. Through melt extrusion and granulation.

Embodiment 2

[0054] (1) Dry PC at 110°C for 4 hours and ABS at 80°C for 3 hours;

[0055] (2) Weigh 65 parts of PC, 35 parts of ABS, 8 parts of MBS, 2 parts of ABS-g-MAH, 3 parts of SMA, 1.5 parts of PET, 2 parts of black masterbatch, 4 parts of adsorbent C, 3 parts of antibacterial agent, antibacterial Pour 0.4 part of oxidizing agent and 0.9 part of chemical deodorant into a high-speed mixing tank, and the stirring speed is 360r / min;

[0056] (3) Add the material mixed in step (2) into the twin-screw extruder with an aspect ratio of 48:1. The temperature inside the barrel of the twin-screw extruder is: 230°C in the first zone, 230°C in the second zone, and 230°C in the third zone. 230°C, 230°C in the fourth zone, 230°C in the fifth zone, 230°C in the sixth zone, 230°C in the seventh zone, 230°C in the eighth zone, 250°C at the head, and the speed of the twin-screw extruder is 260r / min. Through melt extrusion and granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com