Magnesia-alumina spinel-silicon nitride-based honeycomb ceramic heat-absorbing body and preparation method thereof

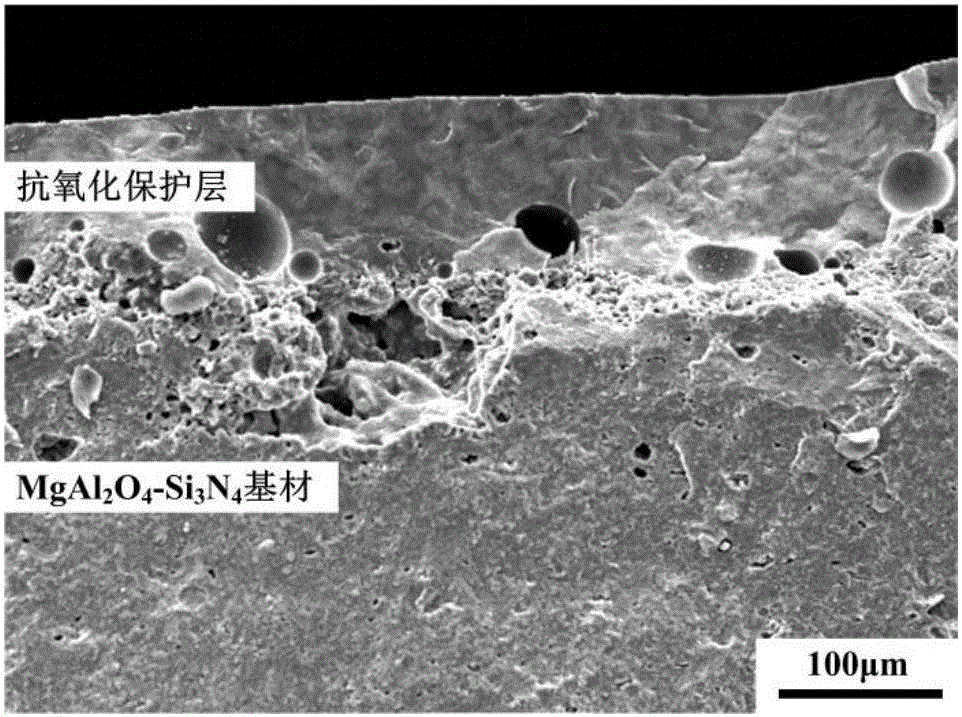

A magnesium-aluminum spinel, honeycomb ceramic technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of poor anti-oxidation performance, low solar light absorption rate, etc., achieve good anti-oxidation performance and improve absorption effect , the effect of increasing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An aluminum spinel-silicon nitride-based honeycomb ceramic heat absorber material, the preparation method of which comprises the following steps:

[0036] 1) Raw material processing: Si3 N 4 、Al 2 o 3 , MgO and TiO 2 The powders are dried at 100°C for standby use, and the particle size of the four powders is 40 μm;

[0037] 2) Mixing of raw materials: Weigh each raw material in proportion, and the mass percentage of each raw material is: Si 3 N 4 60%, Al 2 o 3 26%, MgO 12%, TiO 2 2%, the weighed powder was mixed with a ball mill for 1 hour to obtain a mixed powder; then a plasticizer accounting for 36% of the mass of the mixed powder was added, and mixed with a kneader for 20 minutes to obtain a plastic clay;

[0038] Wherein the plasticizer is composed of carboxymethyl cellulose, tung oil and water, and each component is calculated by mass percentage: carboxymethyl cellulose 8%, tung oil 8%, water 84%;

[0039] 3) Practicing mud and aging: Put the obtained p...

Embodiment 2

[0046] An aluminum spinel-silicon nitride based honeycomb ceramic heat absorber, the preparation method of which comprises the following steps:

[0047] 1) Raw material processing: Si 3 N 4 、Al 2 o 3 , MgO and TiO 2 The powders are dried at 100°C for standby use, and the particle size of the four powders is 60 μm;

[0048] 2) Mixing of raw materials: Weigh each raw material in proportion, and the mass percentage of each raw material is: Si 3 N 4 70%, Al 2 o 3 18%, MgO8%, TiO 2 4%, the weighed powder was mixed with a ball mill for 2 hours to obtain a mixed powder; then a plasticizer accounting for 40% of the mass of the mixed powder was added, and mixed with a kneader for 30 minutes to obtain a plastic clay;

[0049] The plasticizer is composed of binder, lubricant and water, wherein the binder is mixed with carboxymethyl cellulose and polyvinyl alcohol in a mass ratio of 1:1, and the lubricant is made of tung oil and soybean oil in a ratio of 1:1 The mass ratio is m...

Embodiment 3

[0056] An aluminum spinel-silicon nitride based honeycomb ceramic heat absorber, the preparation method of which comprises the following steps:

[0057] 1) Raw material processing: Si 3 N 4 、Al 2 o 3 , MgO and TiO 2 The powders are dried at 100°C for standby use, and the particle size of the four powders is 50 μm;

[0058] 2) Mixing of raw materials: Weigh each raw material in proportion, and the mass percentage of each raw material is: Si 3 N 4 65%, Al 2 o 3 22%, MgO8%, TiO 2 5%, the weighed powder was mixed with a ball mill for 1.5 hours to obtain a mixed powder; then a plasticizer accounting for 45% of the mass of the mixed powder was added, and mixed with a kneader for 25 minutes to obtain a plastic clay;

[0059] Wherein the plasticizer is composed of polyvinyl alcohol, soybean oil and water, and each component is calculated as 9% polyvinyl alcohol, 10% soybean oil and 81% water by mass percentage;

[0060] 3) Practicing mud and aging: Put the obtained plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com