Method of recycling solid waste salts in chemical wastewater

A treatment method and technology for chemical wastewater, applied in chemical instruments and methods, inorganic chemistry, chlorine/hydrogen chloride, etc., can solve the problems of inability to achieve zero discharge of wastewater, groundwater and soil pollution, occupation of land resources, etc., to meet sustainable development. requirements, avoid the occupation of land resources, and reduce the degree of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

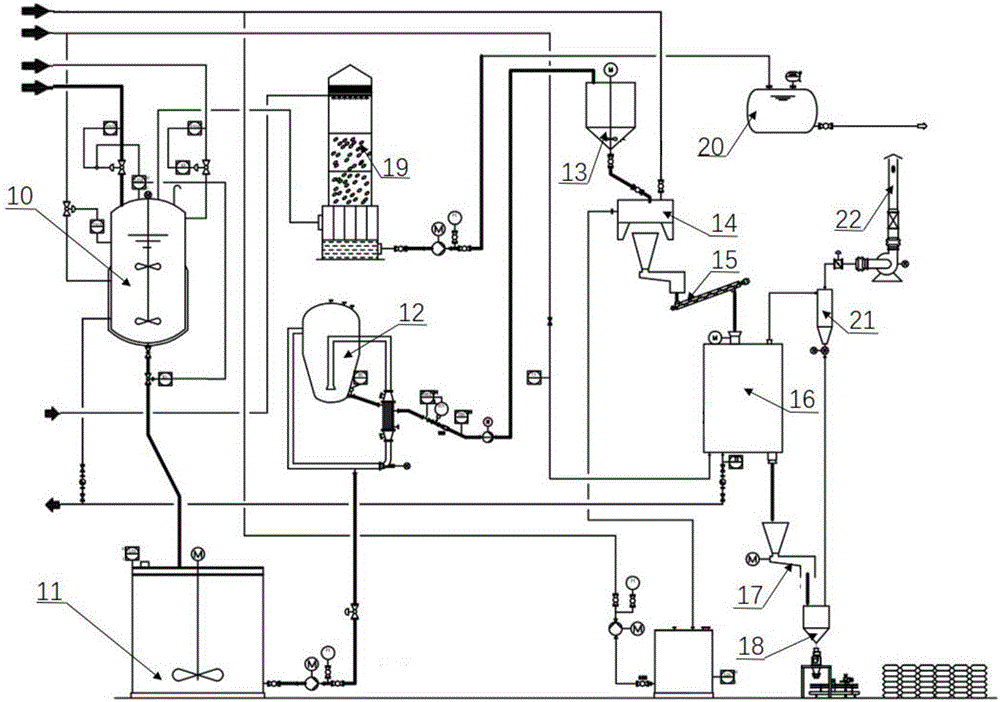

Image

Examples

Embodiment 1

[0034] Add 2.18 tons of solid waste salt to the glass-lined reactor with stirrer, thermal resistance, pressure gauge, liquid level gauge, etc., start the hydrogen chloride absorption and storage system, slowly add 3.11 tons of 90% sulfuric acid, and keep stirring Heat to 135°C by steam, and keep warm for 35min under the condition of 0.2MPa; introduce the reaction liquid into the reaction liquid storage tank containing 0.48 tons of water and mix evenly, and introduce it into the crystallizer through a pump, control the temperature of the crystallizer to 35°C, and the pressure Cooling and crystallization under the condition of 0.1MPa, the sodium bisulfate slurry is thickened through a thickener, the working pressure of the thickener is 0.1MPa, and the working temperature is 25°C, and then enters the high-purity material sling centrifuge, while centrifugal dehydration Add saturated sodium bisulfate solution for washing, the working pressure of the sling centrifuge is 0.08MPa, and ...

Embodiment 2

[0036]Add 2.18 tons of solid waste salt to the glass-lined reactor with stirrer, thermal resistance, pressure gauge, liquid level gauge, etc., start the hydrogen chloride absorption and storage system, slowly add 3.11 tons of 95% sulfuric acid, and keep stirring Heat to 150°C by steam, and keep warm for 38min under the condition of 0.4MPa; introduce the reaction solution into the reaction solution storage tank containing 0.5 tons of water and mix evenly, and introduce it into the crystallizer through a pump, control the temperature of the crystallizer to 40°C, and the pressure Cooling and crystallization under the condition of 0.2MPa, the sodium bisulfate slurry is thickened through a thickener, the working pressure of the thickener is 0.15MPa, and the working temperature is 36°C, and then enters the high-purity material sling centrifuge, while centrifugal dehydration Add saturated sodium bisulfate solution for washing, the working pressure of the sling centrifuge is 0.1MPa, an...

Embodiment 3

[0038] Add 2.18 tons of solid waste salt to the glass-lined reactor with stirrer, thermal resistance, pressure gauge, liquid level gauge, etc., start the hydrogen chloride absorption and storage system, slowly add 3.11 tons of 95% sulfuric acid, and keep stirring Heat to 142°C by steam, and keep warm for 40min under the condition of 0.3MPa; introduce the reaction liquid into the reaction liquid storage tank containing 0.52 tons of water and mix evenly, and introduce it into the crystallizer through the pump, control the temperature of the crystallizer to 38°C, and the pressure Cooling and crystallization under the condition of 0.1MPa, the sodium bisulfate slurry is thickened through a thickener, the working pressure of the thickener is 0.15MPa, and the working temperature is 38°C, and then enters the high-purity material sling centrifuge, while centrifugal dehydration Add saturated sodium bisulfate solution for washing, the working pressure of the sling centrifuge is 0.12MPa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com