Impinging stream mixing reactor with multiple groups of layered symmetric baffles

A technology of mixing reactors and reactors, applied in fluid mixers, chemical/physical/physicochemical stationary reactors, mixers, etc., can solve the limitations of effective mixing capacity, high manufacturing cost of propellers, and limitations of impinging flow technology and other problems, to achieve the effect of improving uniformity and mixing efficiency, improving efficiency and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

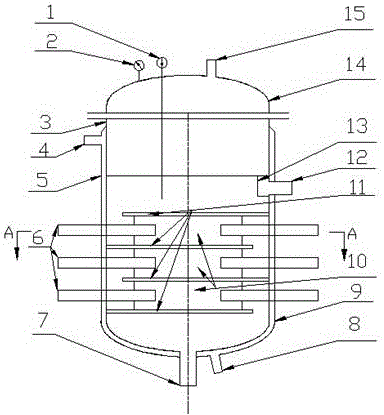

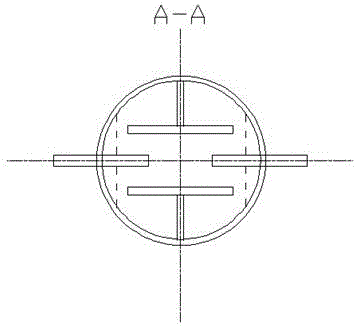

[0022] figure 1 It is a structural schematic diagram of the symmetrical baffle type impinging flow mixing reactor of the present invention.

[0023] In the figure: 1-thermometer, 2-pressure gauge, 3-kettle body, 4, 8-heat exchange medium inlet and outlet, 5-heat exchange jacket, 6-feed pipe, 7-discharge port, 9-kettle bottom , 10-symmetry baffle, 11-baffle plate, 12-overflow port, 13-overflow weir, 14-top cover, 15-gas outlet.

[0024] The reactor is composed of a kettle body 3, a feed pipe 6, an oval kettle bottom 9, and a top cover 14. The main processing material is stainless steel. 14. The lower part is an elliptical kettle bottom 9, the outer wall is provided with a heat exchange jacket 5, the top cover is provided with a gas outlet 15, a pressure gauge 2, and a thermometer 1, the gas outlet can be connected to a vent valve, and the bottom of the kettle is provided with a discharge port 7.

[0025] The working process of the present invention is as follows. Driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com