Acrossocheilus fasciatus puffing sinking compound feed for cage culture

A technology of net cage culture and compound feed, which is applied in the direction of animal feed, animal feed, molding or processing of animal feed, etc., can solve the problem of hindering the development of large-scale breeding of smooth-lipped fish, lack of compound feed for smooth-lipped fish, and Uneven growth and other problems, to achieve the effect of improving intestinal function, stabilizing the source of raw materials, and reducing the bait coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

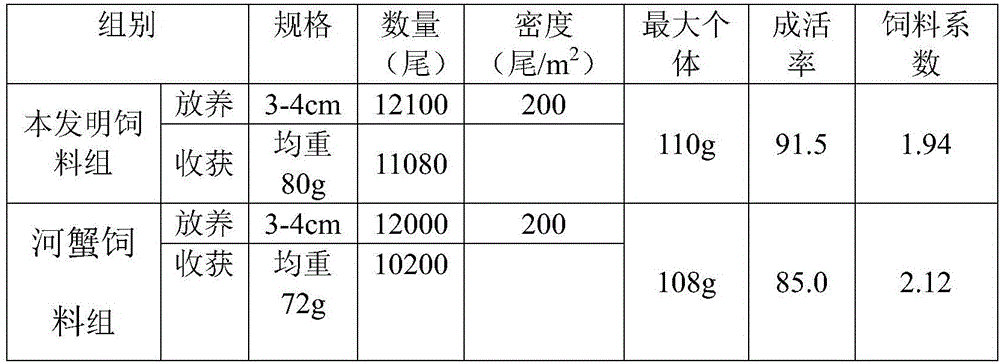

Examples

Embodiment 1

[0034]A kind of puffed lip fish extruded and sinking compound feed for net cage culture is made by mixing the following components in parts by weight: 5 parts of imported super steam red fish meal (origin: Peru, freshness≤100mg / 100g), domestic fish meal ( Freshness ≤ 120mg / 100g) 20 parts, imported meat and bone meal (origin: Uruguay, freshness ≤ 80mg / 100g) 3 parts, domestic defatted shrimp powder (freshness ≤ 100mg / 100g) 5 parts, corn gluten powder 3 parts, yeast 8 parts of flour, 20 parts of peeled soybean meal, 12 parts of imported rapeseed meal, 12 parts of flour, 10 parts of enzyme collagen short fiber, 1.3 parts of calcium dihydrogen phosphate, 0.18 parts of choline chloride, 1.5 parts of soybean oil, soybean lecithin oil 1.0 part, 0.5 part of ginger powder and allicin mixture (mixture of ginger powder and allicin according to the mass ratio of 1:1), 1 part of multidimensional mixture, 1 part of multi-mineral mixture, 0.05 part of composite antioxidant, 2 parts of bentonit...

Embodiment 2

[0040] A kind of puffed lip fish extruded and sinking compound feed for net cage culture is made by mixing the following components in parts by weight: 8 parts of imported super steam red fish meal (origin: Peru, freshness≤100mg / 100g), domestic fish meal ( Freshness ≤ 120mg / 100g) 10 parts, imported meat and bone meal (origin: Uruguay, freshness ≤ 80mg / 100g) 5 parts, domestic defatted shrimp powder (freshness ≤ 100mg / 100g) 3 parts, corn gluten powder 5 parts, yeast 5 parts of flour, 35 parts of peeled soybean meal, 5 parts of imported rapeseed meal, 16 parts of flour, 8 parts of enzyme collagen short fiber, 1.6 parts of calcium dihydrogen phosphate, 0.13 parts of choline chloride, 2.5 parts of soybean oil, soybean lecithin oil 3.0 parts, 1.5 parts of ginger powder and allicin mixture (mixture of ginger powder and allicin according to the mass ratio of 1:1), 1 part of multidimensional mixture, 1 part of multi-mineral mixture, 0.08 parts of composite antioxidant, 1 part of bentoni...

Embodiment 3

[0046] A kind of puffed lip fish extruded and sinking compound feed for net cage culture is made by mixing the following components in parts by weight: 6 parts of imported super steam red fish meal (origin: Peru, freshness≤100mg / 100g), domestic fish meal ( Freshness ≤ 120mg / 100g) 15 parts, imported meat and bone meal (origin: Uruguay, freshness ≤ 80mg / 100g) 4 parts, domestic defatted shrimp powder (freshness ≤ 100mg / 100g) 4 parts, corn gluten powder 4 parts, yeast 7 parts of flour, 30 parts of peeled soybean meal, 8 parts of imported rapeseed meal, 14 parts of flour, 9 parts of enzyme collagen short fiber, 1.5 parts of calcium dihydrogen phosphate, 0.15 parts of choline chloride, 2 parts of soybean oil, soybean lecithin oil 2 parts, 1 part of ginger powder and allicin mixture (mixture of ginger powder and allicin according to the mass ratio of 1:1), 1 part of multidimensional mixture, 1 part of multi-mineral mixture, 0.06 parts of composite antioxidant, 1.5 parts of bentonite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com