Plate-fin type cold storage apparatus

A cold storage device, plate-fin type technology, applied in the field of cold storage devices, can solve the problems of slow storage/discharging rate and inability to respond quickly, and achieve the effect of reducing energy exchange, satisfying rapid cooling rate, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

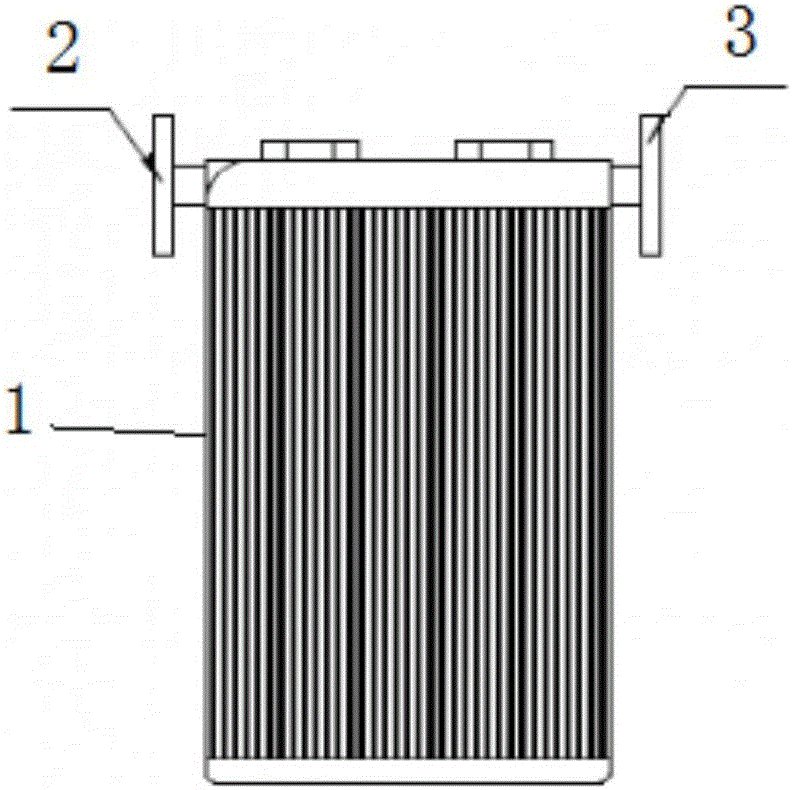

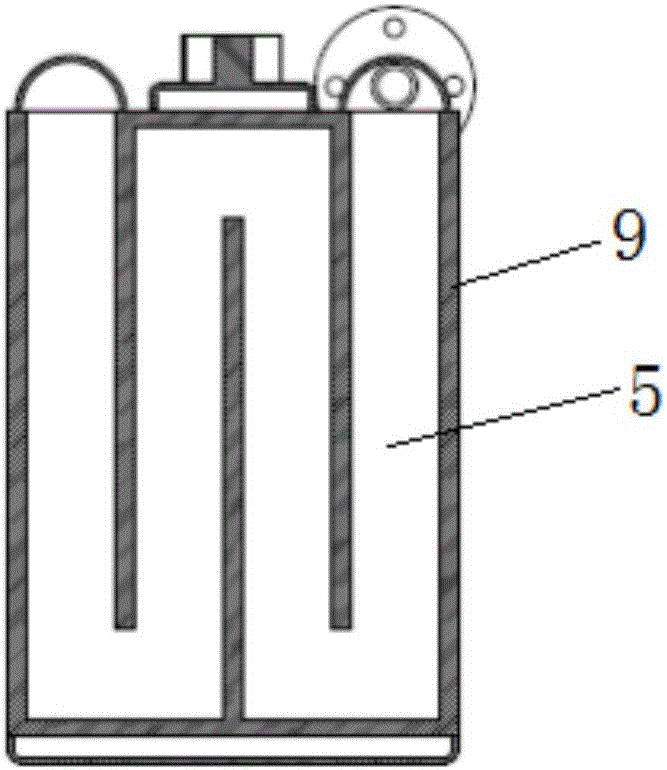

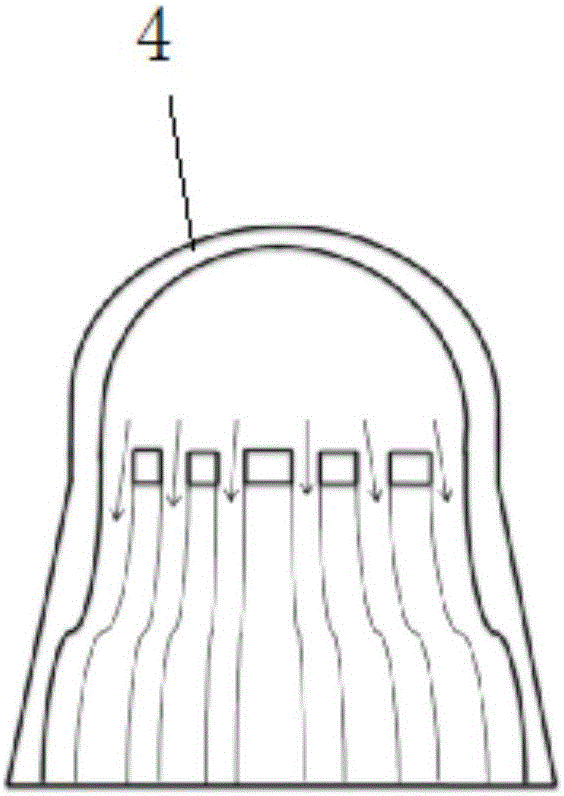

[0027] Such as Figure 1-6 As shown, a plate-fin cold storage device includes a shell 1, which is provided with a flow medium inlet 2 and a flow medium outlet 3, and the shell 1 is provided with a flow distribution device 4 and a multi-layer microchannel cold plate 5 , the microchannel cold plate 5 is provided with a flow medium channel 10, the front end of the flow distribution device 4 is sealed and connected with the flow medium inlet 2, and the two ends of each layer of the microchannel cold plate 5 are respectively sealed with the end of the flow distribution device 4 and the flow medium outlet 3 For connection, fins 6 are obliquely arranged between adjacent two layers of microchannel cold plates 5 , louver structures 7 are arranged on the fins 6 , and paraffin wax 8 is filled between each fin 6 .

[0028] The microchannel cold plate 5 is made of high thermal conductivity aluminum alloy material, bent into a serpentine shape in the housing 1 and separated by baffles 9 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com