Method for preparing ternary cathode material precursor by using waste lithium battery materials

A technology for waste lithium batteries and positive electrode materials, which is applied in the field of preparation of ternary positive electrode material precursors, can solve the problems of particle agglomeration of ternary material precursors, inability to effectively control the particle size and shape of ternary materials, and prevent particles from Agglomeration, improved recovery efficiency, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

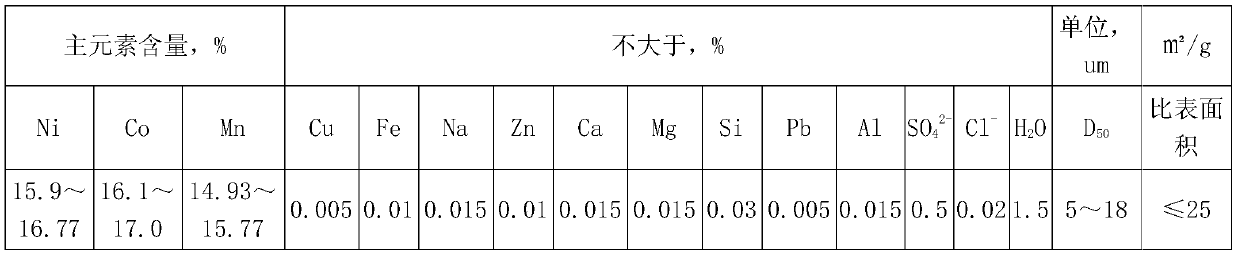

Embodiment 1

[0042] Take 50g of nickel-cobalt-lithium-manganese-manganate positive electrode strips from waste lithium-ion batteries, use nitric acid with a concentration of 8mol / L to stir and leach the positive electrode strips at 55°C for 30min, and filter after leaching to obtain a mixture of nickel, cobalt, manganese, lithium, and aluminum nitrates. solution; add diatomaceous earth, filter to remove impurities that are not dissolved by acid in the positive electrode material, and obtain a mixed solution of nickel, cobalt, manganese, and lithium nitrate; add 15wt.% ascorbic acid to the solution, control the reaction temperature at 30 ° C, and react for 2 hours; After the reaction, use sodium hydroxide solution to adjust the pH value of the solution to 5 to form aluminum hydroxide precipitates. After maintaining for 30 minutes, add diatomaceous earth and filter to remove the aluminum hydroxide precipitates to obtain a mixture containing only divalent nickel, cobalt, manganese and lithium n...

Embodiment 2

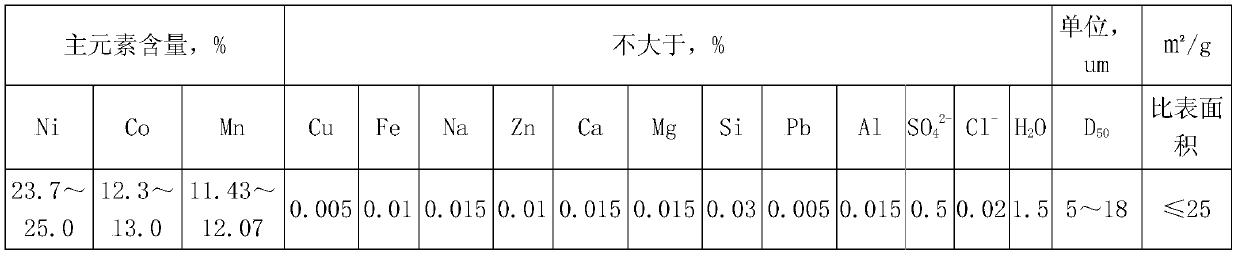

[0046] Get 50g of lithium cobalt oxide and lithium nickel cobalt manganese oxide positive electrode belt of waste lithium ion battery, adopt the nitric acid that concentration is 6mol / L when stirring and leaching 40min to positive electrode belt at 60 ℃, filter after leaching to obtain nickel, cobalt, manganese, lithium, Aluminum nitrate mixed solution; add diatomaceous earth, filter to remove impurities that are not dissolved by acid in the positive electrode material, and obtain nickel, cobalt, manganese, and lithium nitrate mixed solution; add 15wt.% ascorbic acid to the solution, and control the reaction temperature to 40°C , reacted for 1.5h; after the reaction, use sodium hydroxide solution to adjust the pH value of the solution to 4.5 to form aluminum hydroxide precipitate, keep it for 40min, add diatomaceous earth and filter to remove the aluminum hydroxide precipitate, and obtain a solution containing only divalent nickel, cobalt, and manganese Mix solution with lithiu...

Embodiment 3

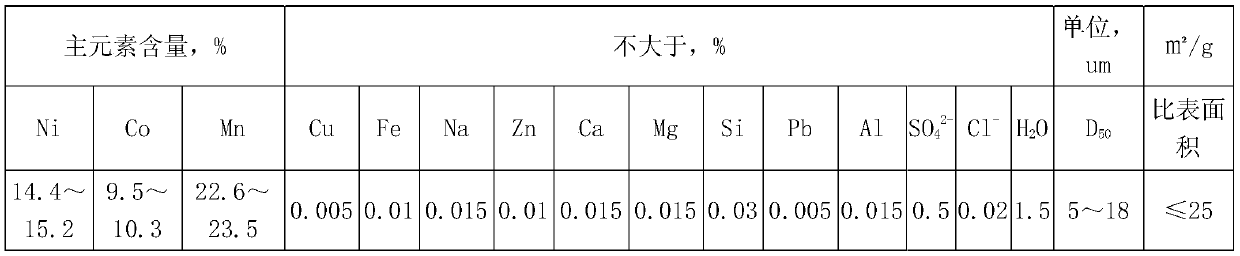

[0050] Take 50g of nickel-cobalt-lithium-manganese-manganate positive electrode strips from waste lithium-ion batteries, use nitric acid with a concentration of 4mol / L to stir and leach the positive electrode strips at 60°C for 50min, and filter after leaching to obtain a mixture of nickel, cobalt, manganese, lithium, and aluminum nitrates. solution; add diatomaceous earth, filter to remove impurities that are not dissolved by acid in the positive electrode material, and obtain a mixed solution of nickel, cobalt, manganese, and lithium nitrate; add 10wt.% ascorbic acid to the solution, control the reaction temperature at 50°C, and react for 1.5h After the reaction, use sodium hydroxide solution to adjust the pH value of the solution to 4, generate aluminum hydroxide precipitate, add diatomaceous earth and filter to remove the aluminum hydroxide precipitate after keeping for 40min, and obtain only divalent nickel, cobalt, manganese and lithium nitrate Mix the solution; add nicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com