A reactor core and its preparation process

A preparation process and reactor technology, applied in the manufacture of inductors/transformers/magnets, transformer/inductor cores, circuits, etc., can solve problems such as cumbersome procedures, expansion of magnetic vibration sound sources, looseness between chips, etc., and achieve simple process Ease of operation, elimination of noise sources, and enhancement of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

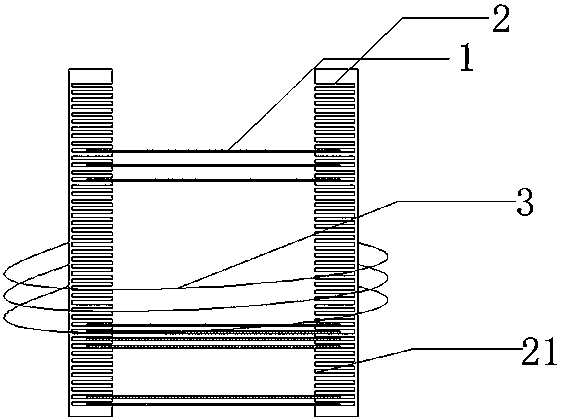

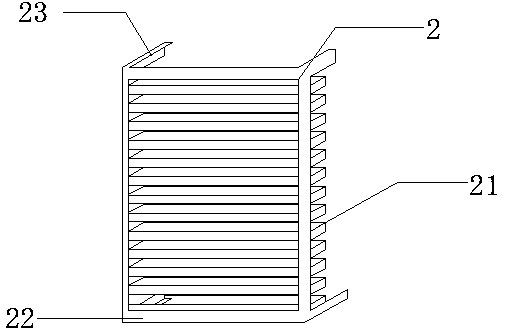

[0018] A reactor core, comprising a number of silicon steel sheets 1, a support frame 2 made of chromium steel and a latitude-free belt 3, the support frame 2 includes a vertical frame surface 22, frame legs 23 perpendicular to the frame surface 22, and The platform 21 parallel to the frame leg 23; the distance between two adjacent platforms 21 on the support frame 2 is equal, and the spacing is 1.1-1.3 times the thickness of the silicon steel sheet 1; the upper and lower si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com