A magnetic fiber optic coupling device

An optical fiber coupling device and magnetic technology, applied in the field of laser, can solve the problems of easy to wear end face loss, great influence of force, inability to rotate, etc., to achieve fast connection speed, high durability, increased stability and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

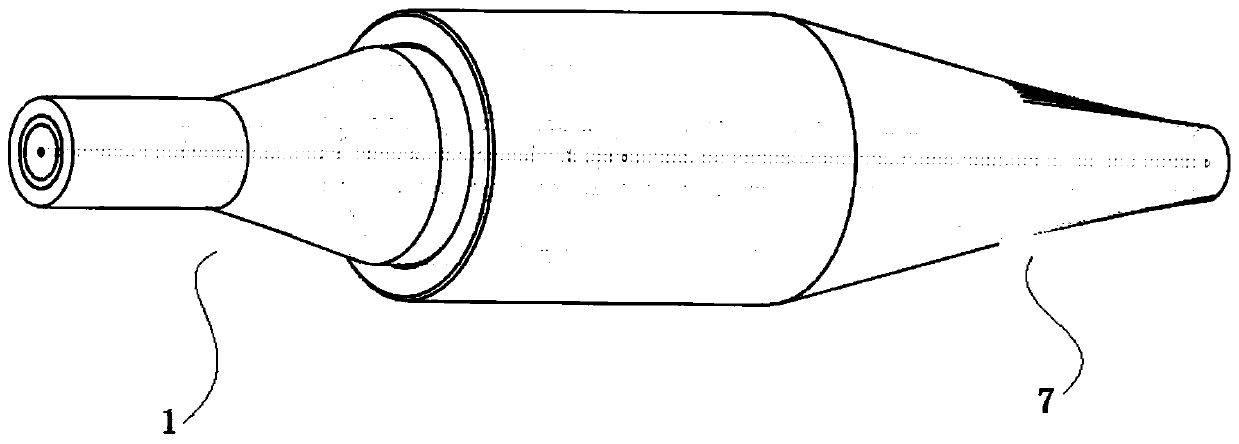

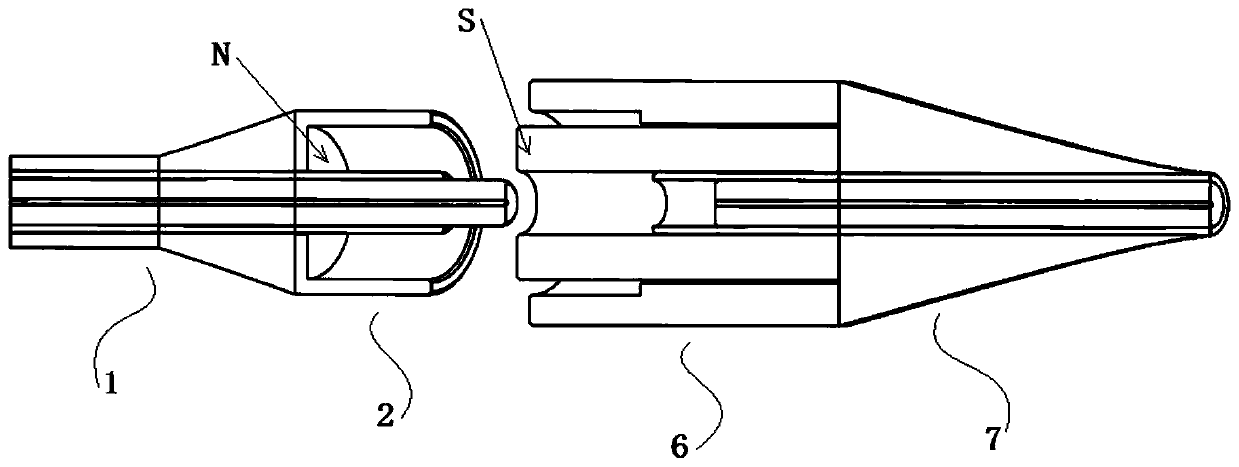

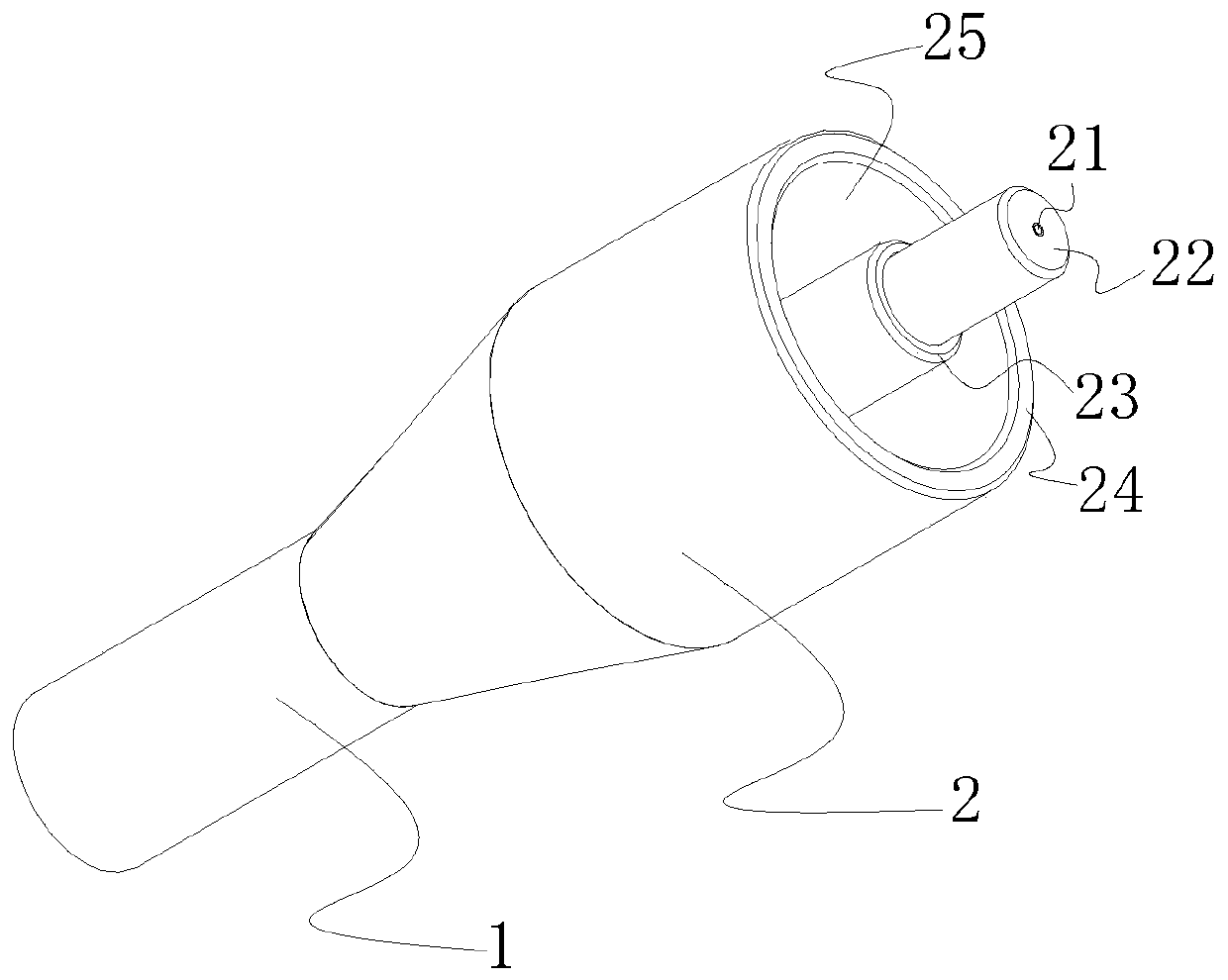

[0040] Such as Figure 1-7 As shown, a magnetic optical fiber coupling device includes a plug and a plug that are inserted into each other. The plug includes a first insertion part 2 and a first connecting part 1 that are fixedly connected to each other. The second plug-in part 6 and the second connection part 7, the free end of the first plug-in part 2 and the free end of the second plug-in part 6 are pluggably connected, and the first plug-in part 2 and the second plug-in part 6 are magnetic and magnetically opposite; the first plug-in part 2 includes a first optical fiber 21 complex and a tube wall 24 arranged outside the first optical fiber 21 complex; the The second insertion part 6 includes a composite body of the second optical fiber 61 and a sleeve disposed outside the composite body of the second optical fiber 61 .

[0041] The magnetism of the first plug-in part 2 and the second plug-in part 6 are opposite so that they can attract each other and the composite of the...

Embodiment 2

[0056] On the basis of Example 1, the method of forming the first plug-in part 2 and the second plug-in part 6 with magnetism can be: using magnetic materials to prepare the first plug-in part 2 and the second plug-in part 2 Two socket parts 6 .

[0057] The magnetic material includes any one of permanent magnetic material (such as NdFeB), soft magnetic material, gyromagnetic material and piezomagnetic material. The permanent magnet material can be NdFeB, such as N52 NdFeB.

Embodiment 3

[0059] On the basis of Example 1, the method of forming the magnetic first plug-in part 2 and the second plug-in part 6 can be: after the first plug-in part 2 and the second plug-in part 6 have been prepared, Electromagnetic magnetization is carried out on the two plug-in parts 6; that is, its magnetism is externally applied.

[0060] The materials for preparing the first plug-in part 2 and the second plug-in part 6 are ceramics, metal or stainless steel, etc., and these materials can be magnetized at a later stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com