Quick-change connector for cable

A cable and plug technology, applied in the field of quick-change cable joints, can solve the problems of easy loosening, slow connection speed, small axial tensile force and radial shear force, etc. Fast insertion speed and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

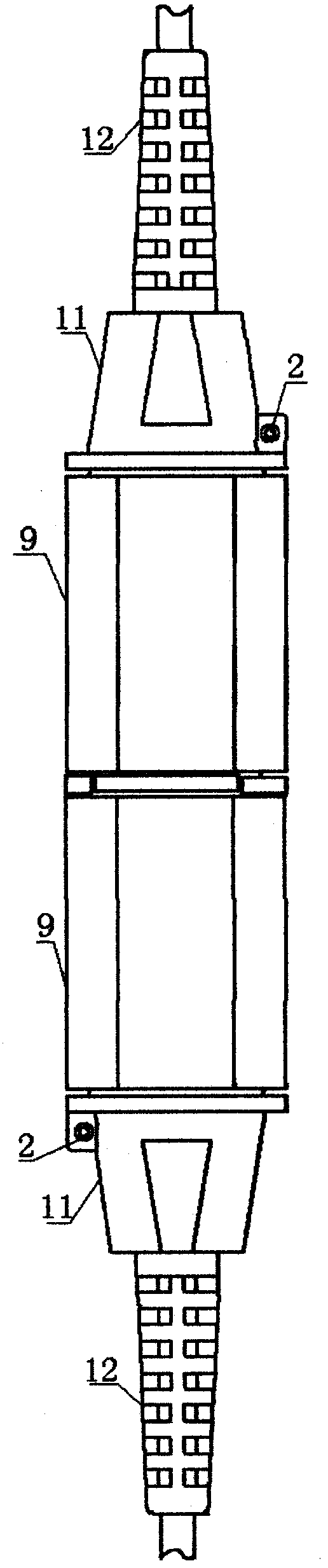

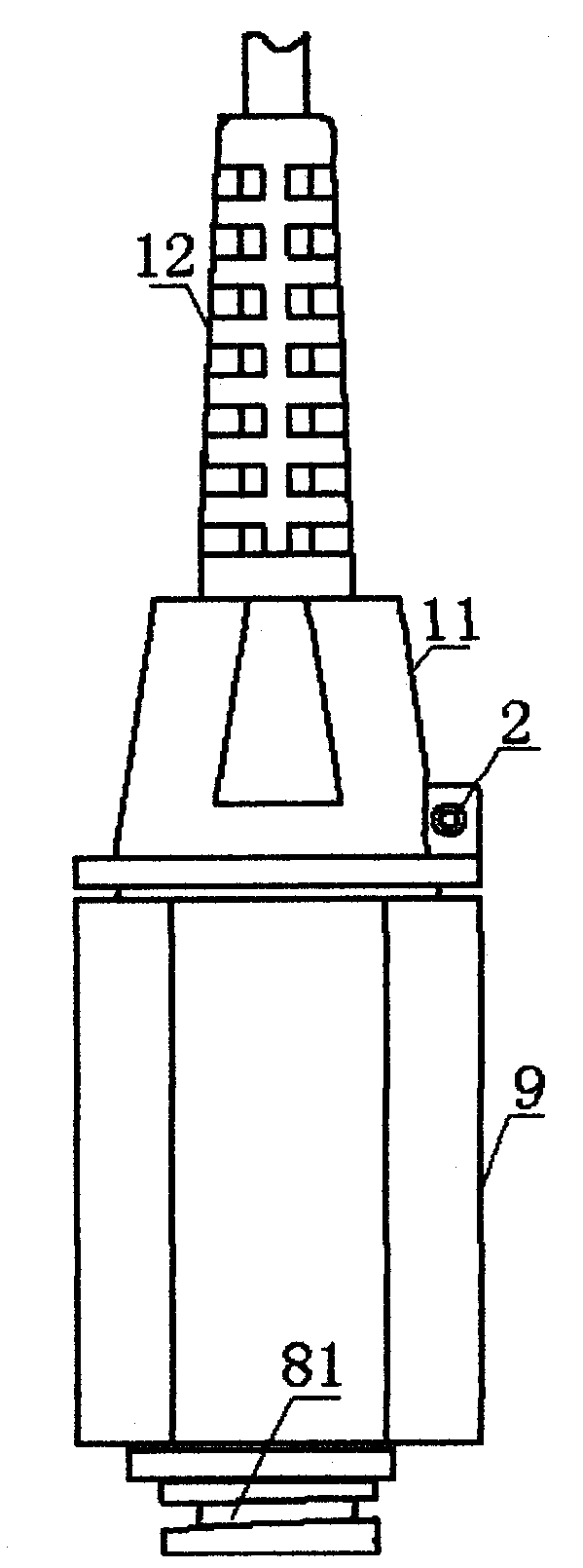

[0027] As shown in the figure, the cable quick change connector of the present invention includes a self-interconnecting plug and a protective cover 5 for the plug. The tail cap 11 of the main body 8 (bucket shape with the opening facing the back), the center of the front end of the main body 8 has a plug-in core, and the main body 8 is formed with a pair of four pairs of relatively distributed protruding forwards on the periphery of the plug-in core. One-third of the arc-shaped outer rib groove chuck 81, the inner circumference of the front end is set between the outer rib groove chuck 81 and the tail cap 11. A pair of quarters that match the outer rib groove chuck 81 of the butt plug main body 8 are provided. One of the locking handles 9 of the arc-shaped internal thread buckle 91; the front center of the protective cover 5 is fixed with an elastic plug 4 for sealing the butt joint core head, and the protective cover 5 is shaped on the outer circumference of the elastic plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com