H2S gas sensitive sensor and preparation method of Co-doped TiO2 nano-tube array films

A technology of nanotube array and gas sensor, which is applied in the field of electronic gas sensor, which can solve the problems of device difficulty and limit the application of sensors, and achieve the effects of short response/recovery time, simple preparation process, and improved gas sensor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

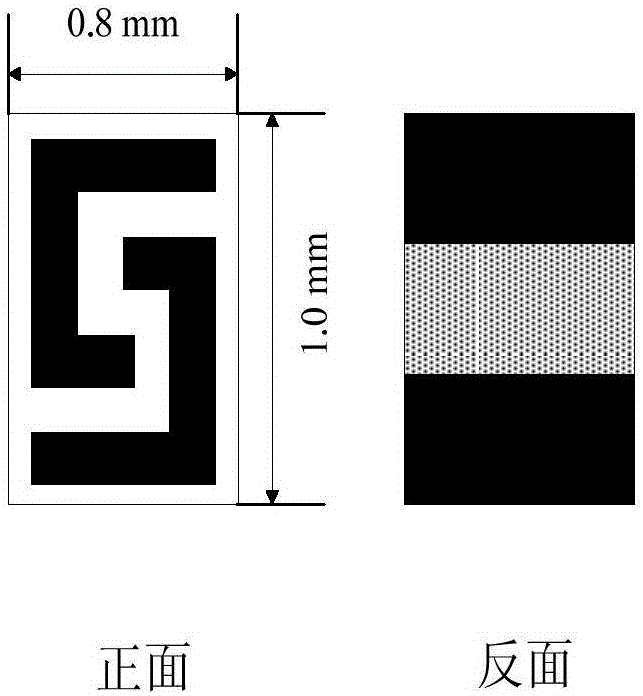

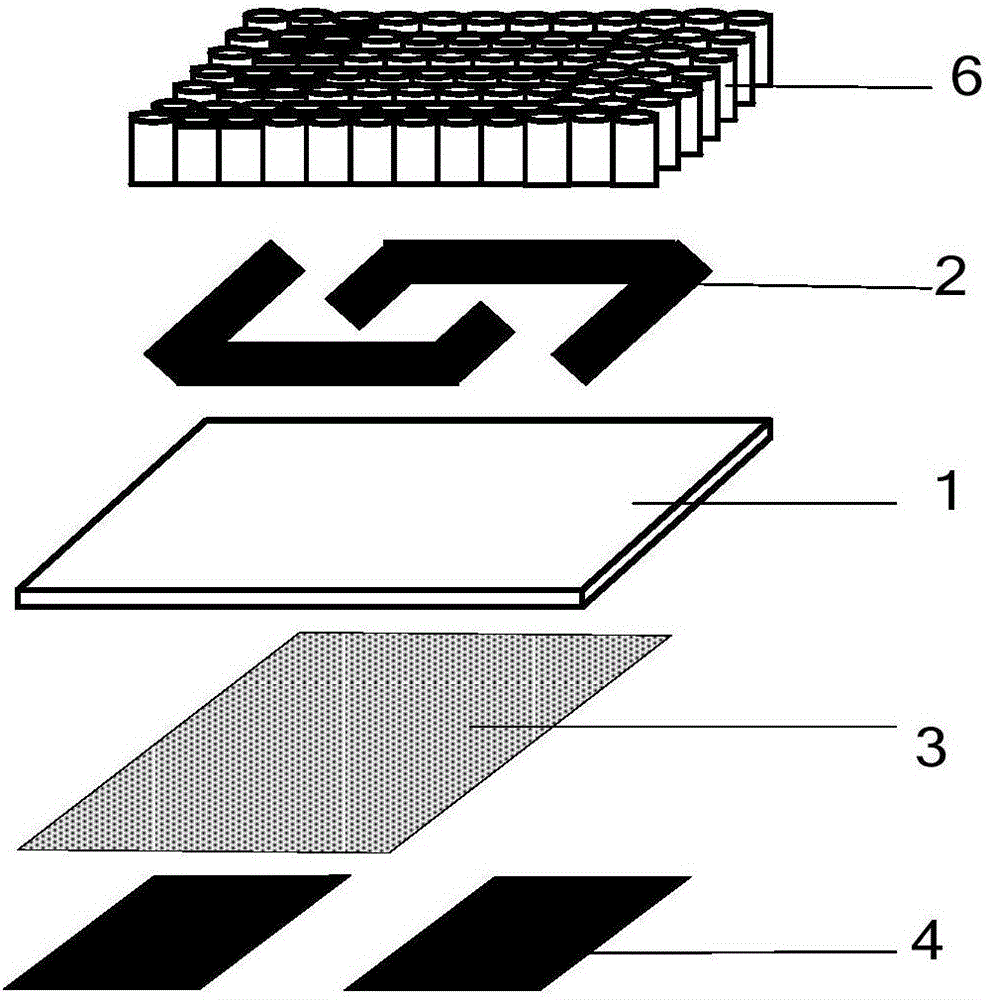

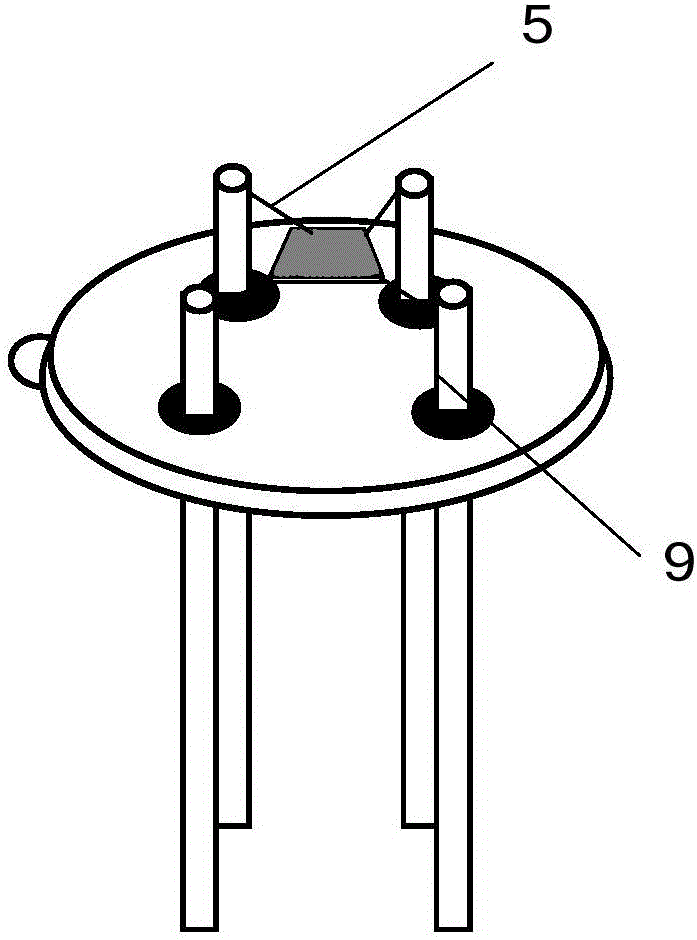

[0037] The preparation of embodiment 1 sensor

[0038] The titanium foil (0.01 mm) was ultrasonically cleaned in acetone, ethanol, and deionized water for 10 min in order to remove the oil on the surface of the titanium foil, and finally dried naturally for later use. The pretreated titanium foil was connected to the positive electrode of the power supply, and the platinum electrode was connected to the negative electrode, and the distance between the two electrodes was 2.5 cm. Place the two poles in the electrolyte, which contains 0.55 wt% NH 4 An ethylene glycol solution of F and 20 wt% deionized water was anodized at 30 V for 2 h at room temperature.

[0039] After the anodic oxidation, cobalt chloride was added to the electrolyte to make the concentration 0.05 M, and the nanotube array was soaked for 1 h. After the reaction, the prepared sample was washed with deionized water, dried naturally and placed in a horse. In the Furnace, in the air atmosphere, the temperature w...

Embodiment 2

[0042] The preparation of embodiment 2 sensor

[0043] The titanium foil (0.01 mm) was ultrasonically cleaned in acetone, ethanol, and deionized water for 10 min in order to remove the oil on the surface of the titanium foil, and finally dried naturally for later use. The pretreated titanium foil was connected to the positive electrode of the power supply, and the platinum electrode was connected to the negative electrode, and the distance between the two electrodes was 2.5 cm. Place the two poles in the electrolyte, which contains 0.55 wt% NH 4 An ethylene glycol solution of F and 20 wt% deionized water was anodized at 30 V for 2 h at room temperature.

[0044] After the anodic oxidation, cobalt chloride was added to the electrolyte to make the concentration 0.1 M, and the nanotube array was soaked for 2 h. After the reaction, the prepared sample was washed with deionized water, dried naturally and placed in a horse. In the Furnace, in the air atmosphere, the temperature wa...

Embodiment 3

[0047] The preparation of embodiment 3 sensor

[0048] The titanium foil (0.01 mm) was ultrasonically cleaned in acetone, ethanol, and deionized water for 10 min in order to remove the oil on the surface of the titanium foil, and finally dried naturally for later use. The pretreated titanium foil was connected to the positive electrode of the power supply, and the platinum electrode was connected to the negative electrode, and the distance between the two electrodes was 2.5 cm. Place the two poles in the electrolyte, which contains 0.55 wt% NH 4 An ethylene glycol solution of F and 20 wt% deionized water was anodized at 30 V for 2 h at room temperature.

[0049] After the anodic oxidation, cobalt chloride was added to the electrolyte to make the concentration 0.1 M, and the nanotube array was soaked for 3 h. After the reaction, the prepared sample was washed with deionized water, dried naturally and placed in a horse. In the Furnace, in the air atmosphere, the temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com