Thermal desorption-gas phase separation-thermal pyrolysis system based on phenylated derived organic mercury

A gas-phase separation and thermal desorption technology, applied in the preparation of test samples, etc., can solve problems such as poor gasification, condensation of samples in pipelines, and inability to meet separation requirements, so as to reduce analysis costs, low prices, and save experiments. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

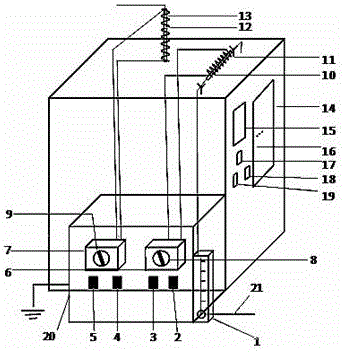

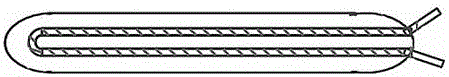

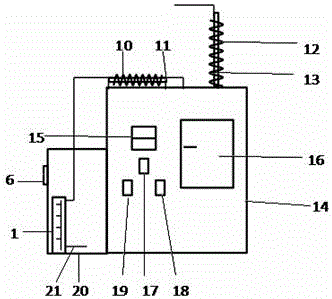

[0020] See Figure 1-5 , A thermal analysis-gas phase separation-pyrolysis system based on phenyl-derived organic mercury, comprising a column box 14 and a pressure and temperature control switch box box 20. The pressure and temperature control switch box box is arranged on one side of the column box. The column box and the pressure regulating and temperature control switch box are provided with thermal analysis components, gas phase separation components, thermal cracking components and auxiliary components; the thermal analysis components include thermal analysis heating wire switch 2, thermal analysis heating wire control time switch 3, The thermal desorption heating wire pressure regulator 6, the thermal desorption heating wire pressure regulator knob 8, the thermal desorption heating wire 10 and the Tenax adsorption tube 11, the Tenax adsorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com