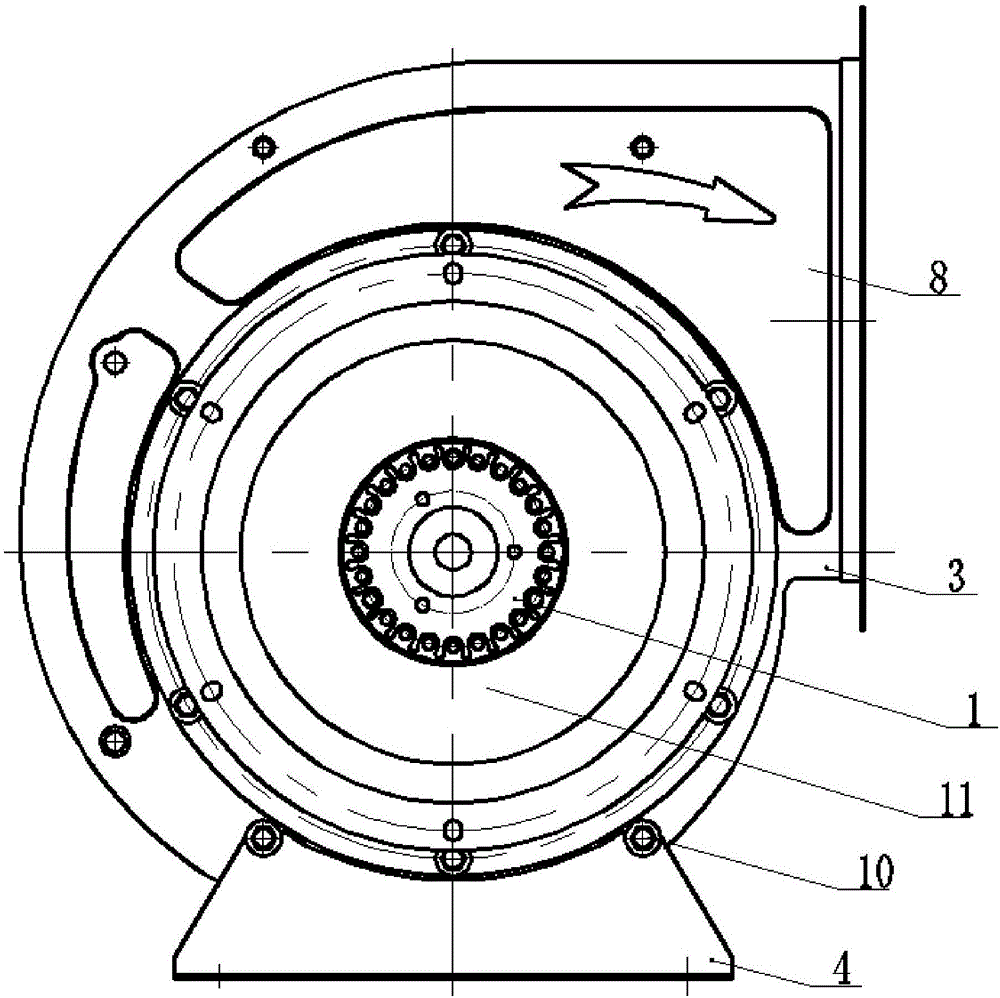

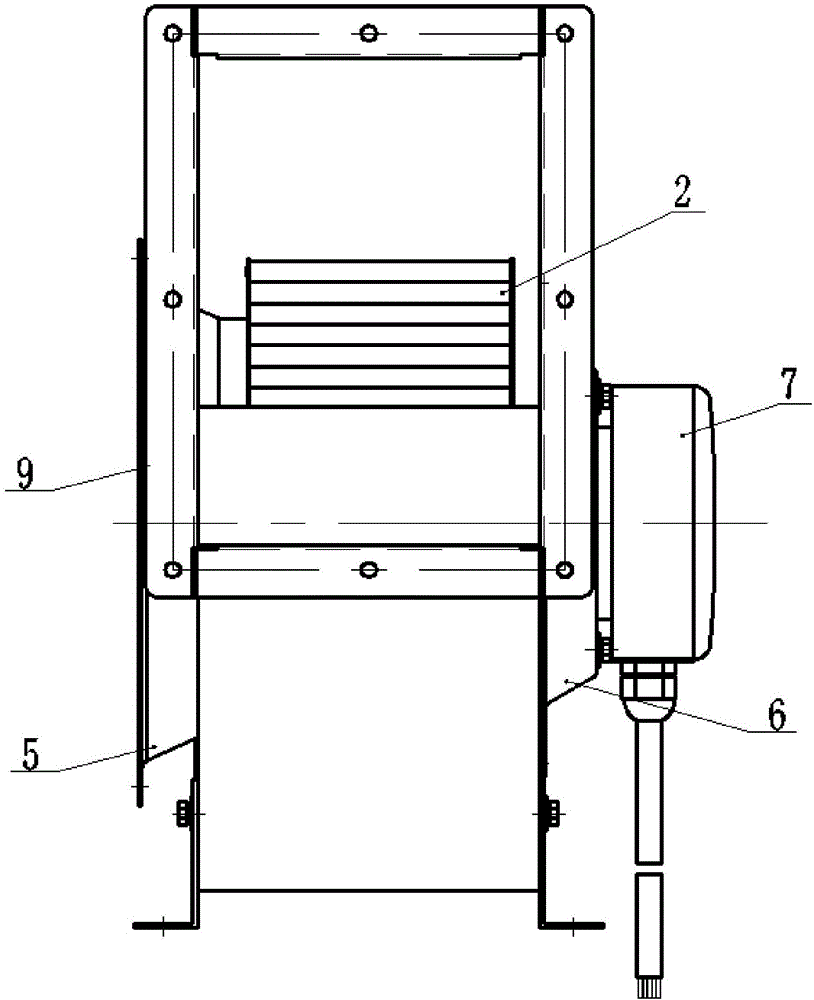

Non-oil-sticking fan impeller

A technology for fan impellers and impellers, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high maintenance cost of exhaust gas, environmental pollution, long production cycle, etc., to improve value and service life, and to achieve good surface finish , The effect of preventing the surface from sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for an oil-free fan impeller, comprising the following steps:

[0029] (1) Degrease the workpiece, and then derust and clean the workpiece through sandblasting and metal spraying;

[0030] (2) Then the rust-removed and cleaned workpieces pass through the inner painting line, which automatically removes dust in real time; the workpieces are preheated and then sprayed with primer (nano Teflon), and then dried and cooled after the primer is sprayed; Then spray the intermediate paint (nano Teflon), spray the top coat (nano Teflon), and then go through the high temperature tunnel furnace for sintering and cooling, then check the off-line

[0031] (3) After that, put the workpiece into the outer painting line, spray the outer paint (nano Teflon) after preheating, and then sinter in the high temperature furnace, cool down and check off the assembly line.

[0032] In the step (3), the sintering temperature of the single-layer oily high-temperature exterior...

Embodiment 2

[0034] A preparation method for an oil-free fan impeller, comprising the following steps:

[0035] (1) Degrease the workpiece, and then derust and clean the workpiece through sandblasting and metal spraying;

[0036] (2) Then the rust-removed and cleaned workpieces pass through the inner painting line, which automatically removes dust in real time; the workpieces are preheated and then sprayed with primer (nano Teflon), and then dried and cooled after the primer is sprayed; Then spray the intermediate paint (nano Teflon), spray the top coat (nano Teflon), and then go through the high temperature tunnel furnace for sintering and cooling, then check the off-line

[0037] (3) After that, put the workpiece into the outer painting line, spray the outer paint (nano Teflon) after preheating, and then sinter in the high temperature furnace, cool down and check off the assembly line.

[0038] In the step (3), the sintering temperature of the single-layer water-based exterior paint is ...

Embodiment 3

[0040] A preparation method for an oil-free fan impeller, comprising the following steps:

[0041] (1) Degrease the workpiece, and then derust and clean the workpiece through sandblasting and metal spraying;

[0042] (2) Then the rust-removed and cleaned workpieces pass through the inner painting line, which automatically removes dust in real time; the workpieces are preheated and then sprayed with primer (nano Teflon), and then dried and cooled after the primer is sprayed; Then spray the intermediate paint (nano Teflon), spray the top coat (nano Teflon), and then go through the high temperature tunnel furnace for sintering and cooling, then check the off-line

[0043] (3) After that, put the workpiece into the outer painting line, spray the outer paint (nano Teflon) after preheating, and then sinter in the high temperature furnace, cool down and check off the assembly line.

[0044] In the step (3), the sintering temperature of the two-layer water-based non-stick outer paint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com