Efficient steel strand wire stay cable saddle

A technology of steel strands and stay cables, applied in the field of bridge structures, can solve the problems of unfavorable steel strands continuing to use, affecting bridge and traffic safety, unbalanced cable force of stay cables, etc., so as to improve the anti-slip performance, prevent the The effect of slippage and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

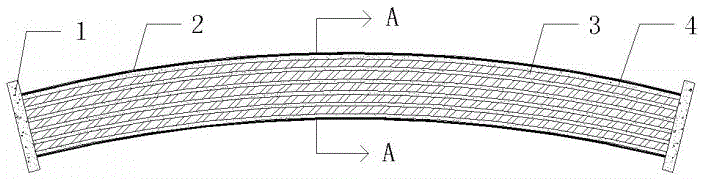

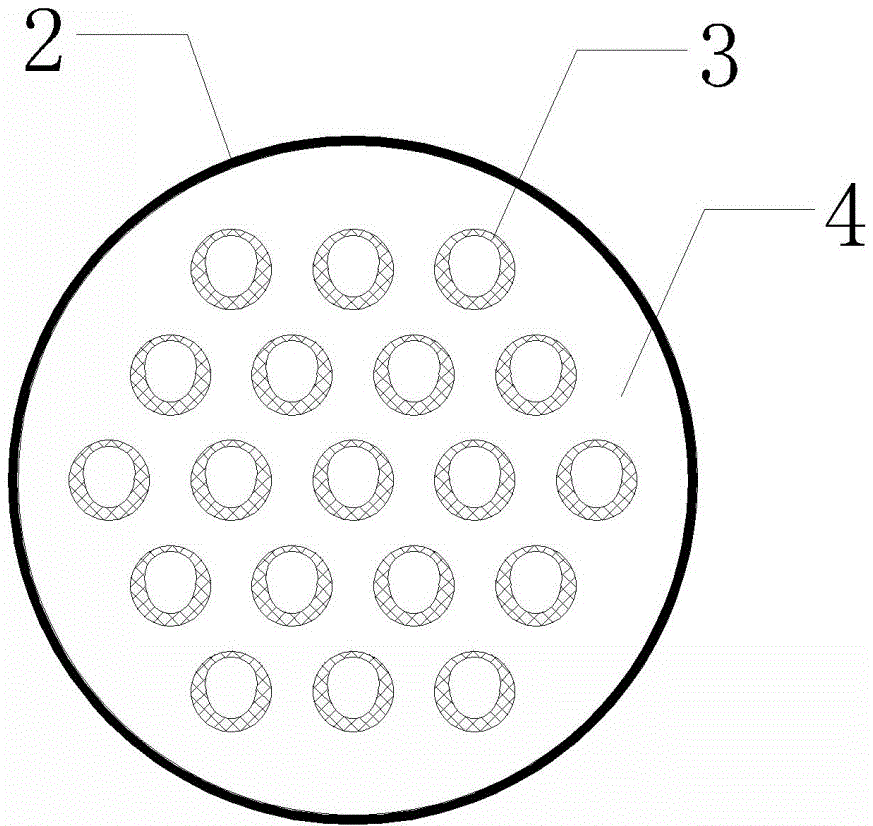

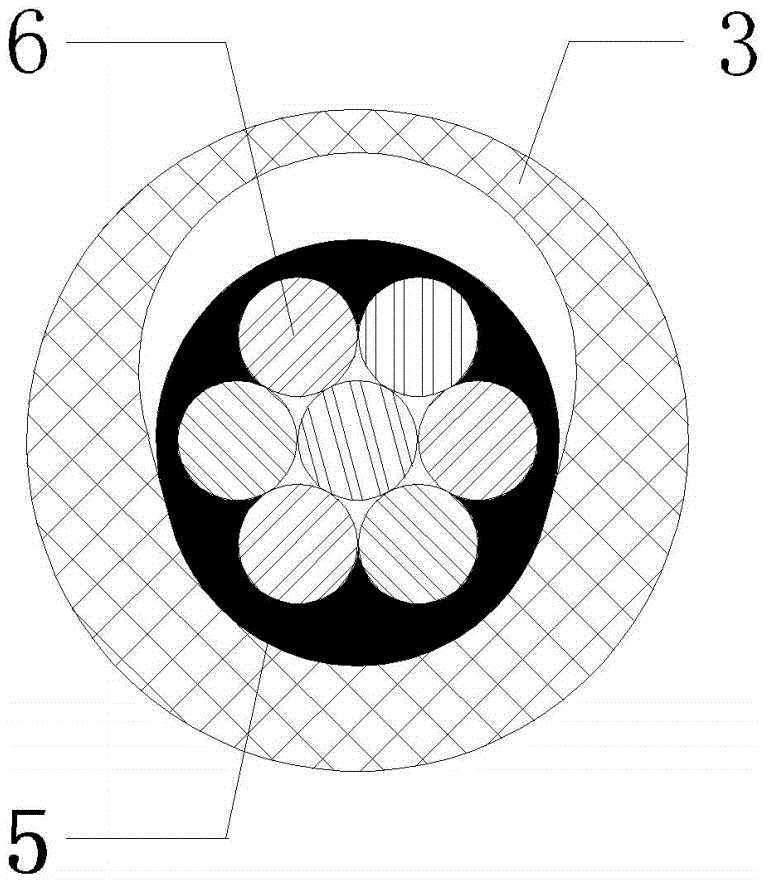

[0017] For the schematic diagram corresponding to this embodiment, see figure 1 , figure 2 with image 3 . The stay cable saddle in the present invention comprises a steel strand 6 , an anchor backing plate 1 , a sleeve 2 , a wire dividing tube 3 , a filling material 4 and a soft metal layer 5 . The filler 4 between the sleeve 2 and the splitter tube 3 is a modified epoxy resin, which is formed by curing the injected modified epoxy resin slurry after the splitter tube 3 is positioned accurately in the sleeve 2 . The outer circumference of the split tube 3 is circular, the upper and lower parts of the inner wall are arc-shaped with different radii, the top is large and the bottom is small, and the middle part is a special-shaped structure with an oblique cut surface. The material of the split tube 3 is high-strength aluminum; A circle of soft metal layer 5 on the periphery of 6 is tin, which is pressed to the periphery of the steel strand 6 in advance, and then correspondin...

Embodiment 2

[0019] For the schematic diagram corresponding to this embodiment, see figure 1 , figure 2 with image 3 . The difference between this embodiment and the first embodiment is that the steel strand 6 is a steel strand with a protective layer specially used for external prestressing. It is necessary to measure the range of the corresponding cable saddle section according to the design data before installing the steel strand 6 on site, strip off the protective layer, and then squeeze the tin band around the steel wire bundle to wrap the steel strand 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com