Method for cation modification and salt-free dyeing of cellulose fabric through one bath

A cellulose fiber and salt-free dyeing technology, which is applied in dyeing, fiber treatment, plant fiber, etc., can solve the problems of poor production environment, large amount of modifier, and deterioration of production environment, and achieve low cost and effective utilization The effect of high efficiency and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

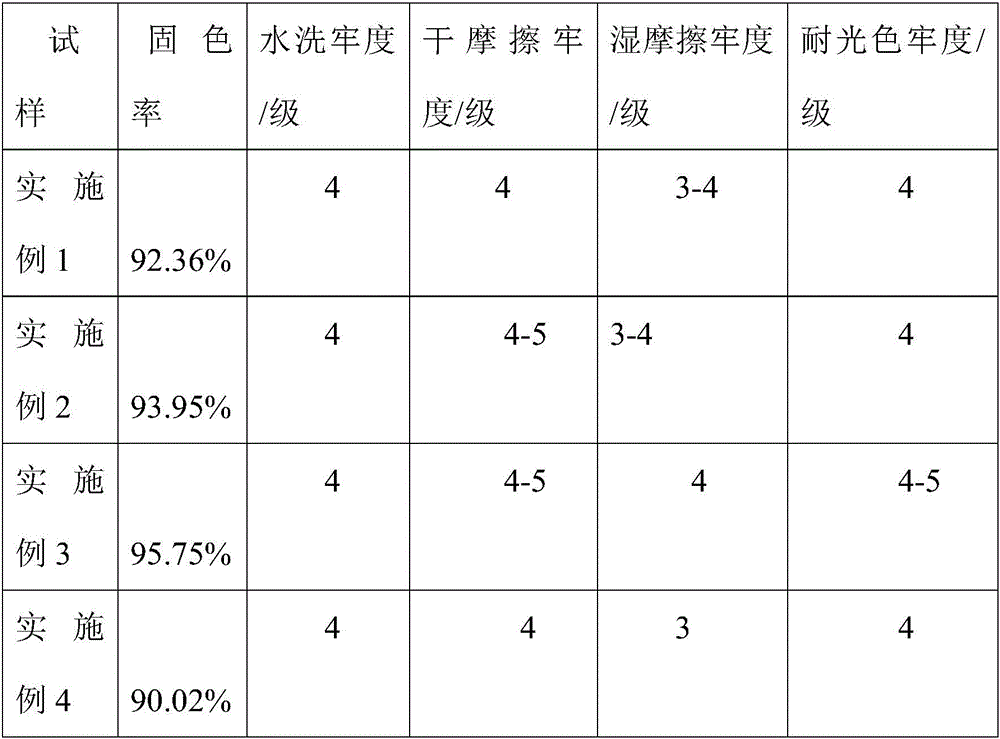

Examples

Embodiment 1

[0019] Cationic modification and salt-free dyeing of rayon twill, the specific steps are:

[0020] (1) Preparation of modified dyeing solution: dissolve sodium hydroxide and dyestuff with soft water respectively, then mix the two evenly, then add 3-chloro-2-hydroxypropyltrimethylammonium chloride to it and mix evenly, A modified dye solution is prepared. The dye prescription is: reactive deep red RF-DA: 5.5g / L, reactive navy blue RF-BF: 36.7g / L, reactive brilliant blue KN-R: 13.3g / L, sodium hydroxide concentration is 16g / L, 3- Chloro-2-hydroxypropyltrimethylammonium chloride concentration is 60g / L;

[0021] (2) Modification and salt-free dyeing of rayon twill fabric: the rayon cloth is modified and dyed by a dipping and rolling process, and the padding solution is the modified dyeing solution prepared in step (1). The rate is 60%, wrapped with plastic film after padding, and placed at room temperature for 18h.

[0022] (3) Washing: wash the cloth modified and dyed by (2) wi...

Embodiment 2

[0024] Cationic modification and salt-free dyeing of cotton poplin, the specific steps are as follows

[0025] (1) Preparation of modified dyeing solution: dissolve sodium hydroxide and dye with soft water respectively, then mix the two evenly, then add 2,3-epoxypropyltrimethylammonium chloride and mix evenly, the dye The prescription is: reactive yellow HF-4GL 150%: 7.7g / L, reactive turquoise FG 150%: 31.7g / L, reactive blue FN-R: 1.8g / L, sodium hydroxide concentration is 9g / L, 2, The concentration of 3-epoxypropyltrimethylammonium chloride is 40g / L.

[0026] (2) Modification and salt-free dyeing of cotton poplin: the cotton poplin is modified and dyed by a dipping and rolling process, the padding solution is the modified dyeing solution prepared in step (1), room temperature padding, padding The rate is 75%, wrapped with plastic film after padding, and placed at room temperature for 17h.

[0027] (3) Washing: washing the cloth after the modification and dyeing in step (2) w...

Embodiment 3

[0029] Cationic modification and salt-free dyeing of cotton / modal fabric

[0030] Preparation of modified dyeing solution: Dissolve sodium hydroxide and dye in soft water respectively, then mix the two evenly, and then add 2,3-epoxypropyltrimethylammonium chloride and 3-chloro-2-hydroxy Propyltrimethylammonium chloride and mix well, the dye prescription is: Reactive Yellow HF-4GL 150%: 2.4g / L, Reactive Turquoise FG 150%: 15.5g / L, Reactive Navy Blue 2GN: 5.4g / L . The concentration of sodium hydroxide is 7g / L, the concentration of 2,3-epoxypropyltrimethylammonium chloride is 6g / L, and the concentration of 3-chloro-2-hydroxypropyltrimethylammonium chloride is 24g / L

[0031] (2) Cotton / modal fabric modification and salt-free dyeing: the cotton / modal fabric is modified and dyed by one dipping and one padding process, and the padding solution is the modified dyeing solution prepared in step (1), which is padded at room temperature, The excess rate is 90%. After padding, it is wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com