Durable flame-retardant finish method for cotton fabric based on ultraviolet light curing reaction

A curing reaction and flame retardant finishing technology, applied in physical treatment, flame retardant fiber, fiber treatment, etc., can solve the problems of difficult wall thickness control, high preparation cost, stiff hand feeling, etc., and achieve good application prospects and flame retardant effect Obvious, simple and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

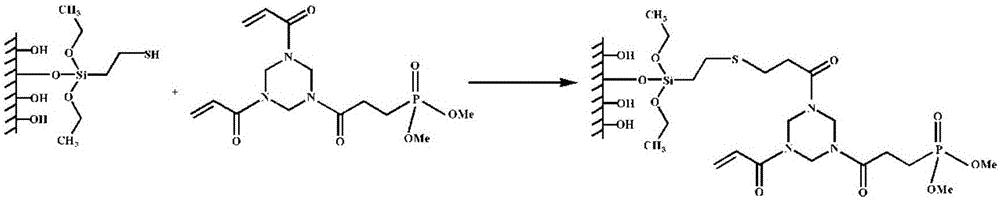

[0034] Use 3-mercaptopropyltriethoxysilane to modify the cotton fabric, and react with the synthetic flame retardant DHTP to make the cotton have good flame retardant properties. The specific steps are:

[0035] (1) Pre-processing stage:

[0036] ①Prepare 15g / L sodium hydroxide and 7g / L PingPingO solution, and wash the cotton fabric for 20min at 70°C;

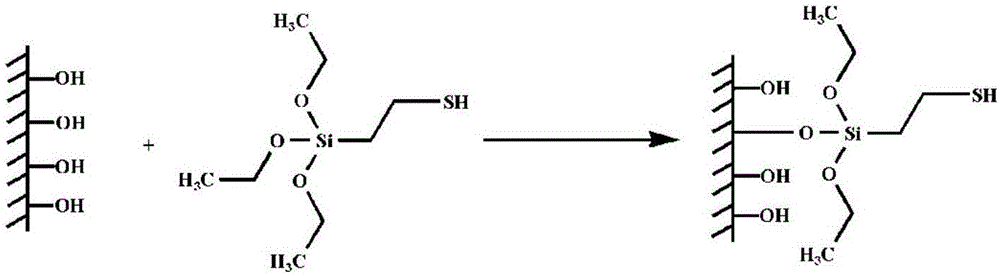

[0037] ②Prepare 1wt% 3-mercaptopropyltriethoxysilane ethanol / water mixed solution (80:20 by volume), adjust the pH to 3.5 with acetic acid, seal the beaker with a thin film, and place it in a constant temperature magnetic stirring water bath for 25 ℃ shaking treatment for 30 minutes, and then soak the washed cotton fabric in the solution for 3 minutes.

[0038] ③Take out the cotton fabric and bake it at a high temperature of 120°C for 5 minutes.

[0039] (2) Synthesis stage

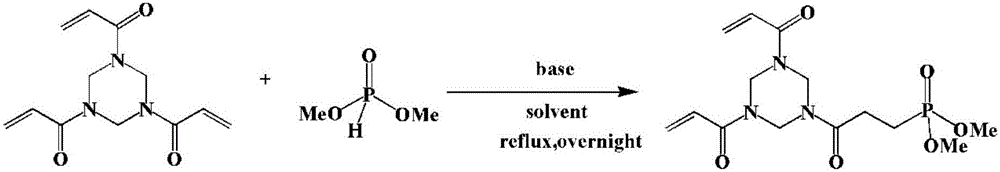

[0040] ① Dissolve THAT and DP in chloroform, place in a constant temperature magnetic stirring water bath, condense and reflux, add DBU dropwise at 65°...

Embodiment 2

[0048] Use 3-mercaptopropyltriethoxysilane to modify the cotton fabric, and react with the synthetic flame retardant DHTP to make the cotton have good flame retardant properties. The specific steps are:

[0049] (1) Pre-processing stage:

[0050] ①Prepare 15g / L sodium hydroxide and 7g / L PingPingO solution, and wash the cotton fabric for 20min at 70°C;

[0051] ②Prepare 2wt% 3-mercaptopropyltriethoxysilane ethanol / water mixed solution (volume ratio 80:20), adjust the pH to 3.5 with acetic acid, seal the beaker with a film, place it in a constant temperature magnetic stirring water bath, 25 ℃ shaking treatment for 30 minutes, and then soak the washed cotton fabric in the solution for 3 minutes.

[0052] ③Take out the cotton fabric and bake it at a high temperature of 120°C for 5 minutes.

[0053] (2) Synthesis stage

[0054] ① Dissolve THAT and DP in chloroform, place in a constant temperature magnetic stirring water bath, condense and reflux, add DBU dropwise at 65°C, TAHT:D...

Embodiment 3

[0062] Use 3-mercaptopropyltriethoxysilane to modify the cotton fabric, and react with the synthetic flame retardant DHTP to make the cotton have good flame retardant properties. The specific steps are:

[0063] (1) Pre-processing stage:

[0064] ①Prepare 15g / L sodium hydroxide and 7g / L PingPingO solution, and wash the cotton fabric for 20min at 70°C;

[0065] ②Prepare 5wt% 3-mercaptopropyltriethoxysilane ethanol / water mixed solution (volume ratio 80:20), adjust the pH to 3.5 with acetic acid, seal the beaker with a film, place it in a constant temperature magnetic stirring water bath, 25 ℃ shaking treatment for 30 minutes, and then soak the washed cotton fabric in the solution for 3 minutes.

[0066] ③Take out the cotton fabric and bake it at a high temperature of 120°C for 5 minutes.

[0067] (2) Synthesis stage

[0068] ① Dissolve THAT and DP in chloroform, place in a constant temperature magnetic stirring water bath, condense and reflux, add DBU dropwise at 65°C, TAHT:D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com