Automatic silk reeling machine groping end basin

The technology of a silk reeling machine and a soxue pot is applied in the field of soxie pots, which can solve the problems of short cleaning cycle of the soxue pot, and achieve the effects of saving cleaning times, reducing consumption and improving cleaning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

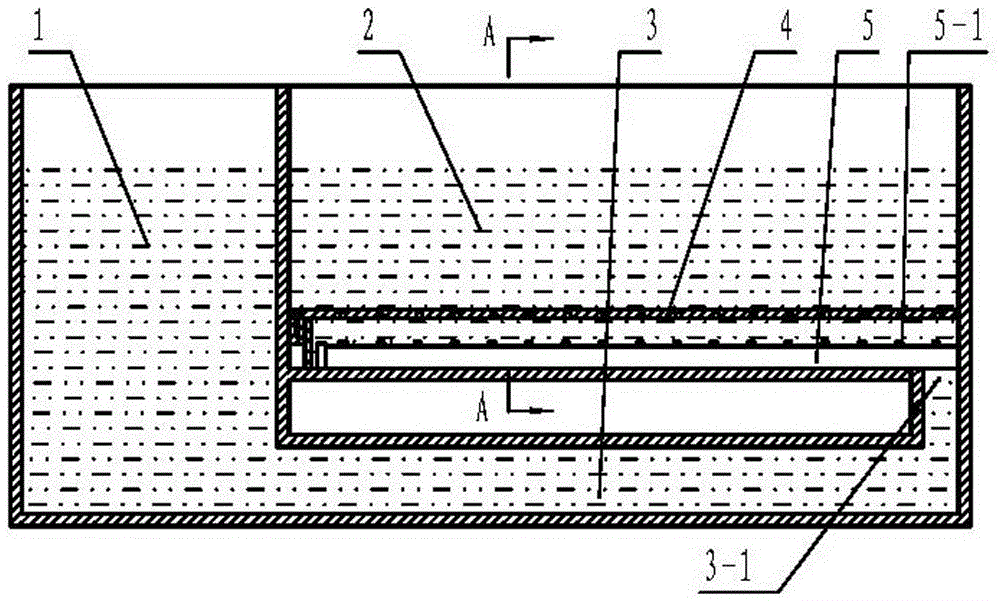

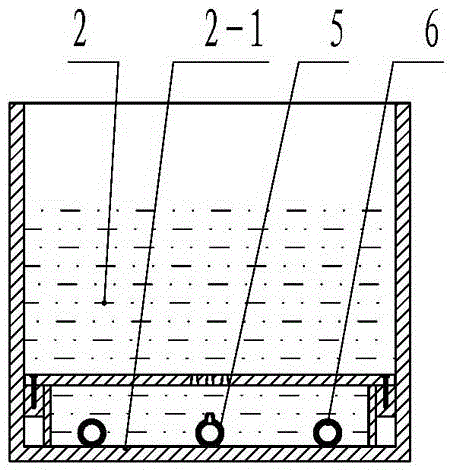

[0013] Such as figure 1 and figure 2 The shown automatic silk reeling machine Suoxu pot body 2 and water tank 1, the pot body 2 includes a bottom plate 2-1 and two steam pipes 6 arranged on the bottom plate 2-1, and a cover is provided above the two steam pipes 6 The plate 4 and the cover plate 4 are stainless steel plates; in the present embodiment, a hot water pipe 5 with a plurality of water spray heads 5-1 is provided in the two steam pipes 3, and the cover plate 4 above the water spray heads 5-1 Three rows of small through holes are arranged along the length direction of the hot water pipe 5; Above the line, the small through hole is a tapered hole with a small upper part and a larger lower part; a water inlet 3-1 is provided on the bottom plate 1-1, and the water inlet 3-1 is connected with the water tank 1 through the water inlet pipe 3 to realize the water in the pot body 2. The water is communicated with the water tank 1 through the water inlet pipe 3, so that the ...

Embodiment 2

[0015] The pitch of the three rows of small through holes is 45 mm, and the rest of the features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com