A kind of high softening point asphalt particle, its preparation method and application

A high softening point asphalt and particle technology, applied in chemical instruments and methods, construction, building components, etc., can solve the problems of poor particle deformability, complex method and process, and achieve excellent high temperature performance, improve yield and stability. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

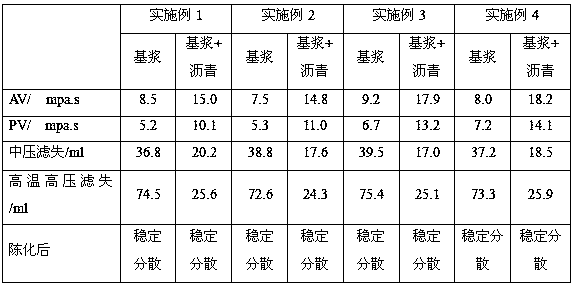

Examples

Embodiment 1

[0031] Take 400g of oxidized asphalt with a softening point of 123.4°C and add it into water and use a high-shear emulsifier to pulverize it for 30 minutes, then add 8g of stearylamine polyoxyethylene ether and 0.1g of isopropanol and continue mixing for 10 minutes to obtain asphalt liquid; The sulfur powder is placed in a sulfur-melting tank and heated to 135°C, kept for 20 minutes, and then enters the reactor. The temperature of the reactor is controlled at 540°C, and N 2 , keep the pressure at 1.0MPa. This condition was maintained for 30 minutes. Then open the discharge valve at the bottom of the reaction kettle, quickly spray the steam containing polymerized sulfur into the prepared asphalt liquid for rapid cooling, keep it at 50°C for 40 minutes, fully solidify and stabilize, and then dehydrate and pump Vacuum drying process. The resulting solid is sieved with a vibrating sieve to obtain high softening point asphalt granules.

Embodiment 2

[0033] Take 425g of solvent-deoiled asphalt with a softening point of 138.5°C and add it to water and use a high-shear emulsifier to pulverize it for 35 minutes, then add 6.5g of fatty alcohol polyoxyethylene ether (AEO-7) and 0.35g of diisopropyl yellow disulfide The orthoester continued to mix for 20 minutes to obtain asphalt liquid; put 75g of sulfur powder in a sulfur melting kettle and heat it to 140°C, keep it for 25 minutes, and then enter the reaction kettle, the temperature of the reaction kettle was controlled at 550°C, and N 2 , to maintain a pressure of 0.8MPa. This condition was maintained for 30 minutes. Then open the discharge valve at the bottom of the reaction kettle, quickly spray the steam containing polymerized sulfur into the prepared asphalt liquid for rapid cooling, keep it at 55°C for 50 minutes, fully solidify and stabilize, and then dehydrate and pump Vacuum drying process. The resulting solid is sieved with a vibrating sieve to obtain high softenin...

Embodiment 3

[0035] Take 350g of natural asphalt with a softening point of 143.6°C and add it to water and use a high-shear emulsifier to pulverize it for 40 minutes, then add 4.5g of dodecylamine polyoxyethylene ether and 0.2g of 4-chloro-1-butanol and continue mixing for 25 minutes. To obtain asphalt liquid; put 150g of sulfur powder in a sulfur melting kettle and heat it to 130°C, keep it for 45 minutes, and then enter the reaction kettle, the temperature of the reaction kettle is controlled at 580°C, and N 2 , to maintain a pressure of 0.6 MPa. This condition was maintained for 40 minutes. Then open the discharge valve at the bottom of the reaction kettle, quickly spray the steam containing polymerized sulfur into the prepared asphalt liquid for rapid cooling, keep it at 60°C for 40 minutes, fully solidify and stabilize, and then dehydrate and pump Vacuum drying process. The resulting solid is sieved with a vibrating sieve to obtain high softening point asphalt granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com