Proton conductive MOF (metal-organic framework) structure compound and preparation method thereof

A metal-organic framework, proton conduction technology, applied in the direction of iron-organic compounds, can solve problems such as coarse pores, and achieve the effects of high thermal stability, simple preparation process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

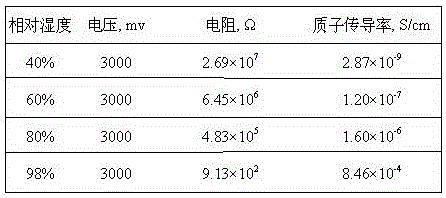

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the proton-conductive metal-organic framework compound described above is characterized in that it comprises the following steps:

[0019] (1) Fe 3 (μ 3 -O)(COOCH 3 ) 6 Synthesis: under stirring conditions, sequentially add sodium acetate, ferric nitrate, and ferrous sulfate into distilled water until the color of the solution is brown, then stop stirring, let it stand for 12-24 hours, filter, wash, and wash the filtered The cake was vacuum dried at 80°C to obtain Fe 3 (μ 3 -O)(COOCH 3 ) 6 ;

[0020] (2) the Fe described in step (1) 3 (μ 3 -O)(COOCH 3 ) 6 After mixing well with [1,1'3'1']terphenyl-4,5',4'-tricarboxylic acid and imidazole, dissolve the mixture in N,N'-diethylformamide and add acetic acid , transfer the solution to an airtight reactor and react for 30 hours under autogenous pressure at 150°C. After the reaction, cool naturally at room temperature, filter, wash, and dry to obtain a metal-organic framework compound with...

Embodiment 1

[0025] Under stirring, dissolve 24.6 grams of sodium acetate (0.3 mol) into 100 ml of distilled water to dissolve, then filter the solution under normal pressure to remove insoluble impurities, and slowly add 8.1 grams of iron nitrate (0.02 mol) to the filtrate , after it is completely dissolved, add 27.8 grams of ferrous sulfate (0.1 mol) in batches, and stir for about 1 hour. At this time, the color of the solution is brown. After that, the solution is left to settle for 12 hours, filtered under reduced pressure, and washed with distilled water. Three times, three times with absolute ethanol. Finally, the washed filter cake was vacuum-dried at 80°C to obtain 14 grams of Fe 3 (μ 3 -O)(COOCH 3 ) 6 .

[0026] 0.015 g Fe 3 (μ 3 -O)(COOCH 3 ) 6After mixing well with 0.015 g of [1,1'3'1']terphenyl-4,5',4'-tricarboxylic acid and 0.015 g of imidazole, the mixture was dissolved in 4 mL of N,N'-diethylmethyl amide, and add 0.35 ml of acetic acid, transfer the solution to a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com