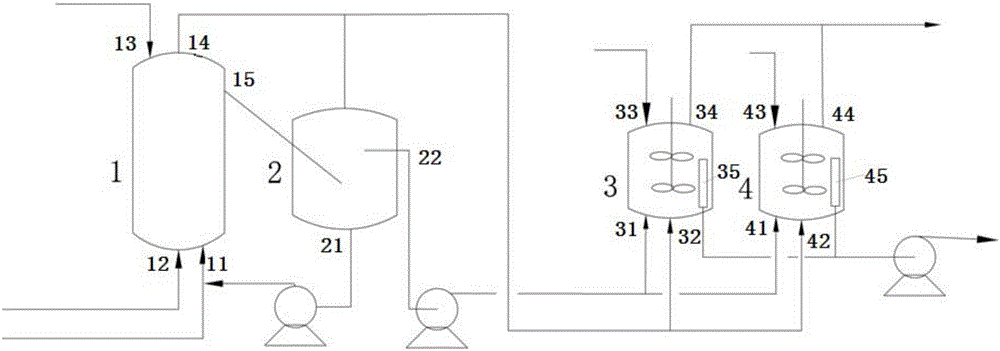

Device and method for preparing propylene oxide

A technology of propylene oxide and epoxidation reaction, which is applied in the production of bulk chemicals and organic chemistry, etc. It can solve the problems of overheating, high reaction temperature, and low selectivity of the product propylene oxide, so as to avoid the formation of hot spots , The epoxidation reaction is mild, and the effect of overcoming the problem of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Adopt the method for above-mentioned device to prepare propylene oxide:

[0061] (1) Preparation of high-strength titanium silicalite molecular sieve microspheres

[0062] TS-1 zeolite is prepared by traditional hydrothermal synthesis method: mix and stir ethyl orthosilicate, tetrabutyl titanate, isopropanol, tetrapropylammonium hydroxide and deionized aqueous solution evenly to obtain gel, gel Medium SiO 2 : TiO 2 :TPAOH:H 2 The molar ratio of O is 1:0.025:0.3:25; distill off isopropanol and ethanol generated by hydrolysis; then move the gel to a hydrothermal synthesis kettle with polytetrafluoroethylene, and crystallize at 170°C for 48h . The crystallized product was filtered, fully washed, dried in the air atmosphere at 110°C for 12 hours, and calcined in the air atmosphere at 550°C for 3 hours to obtain nanometer TS-1 zeolite.

[0063] The nanometer TS-1 zeolite is evenly dispersed in the silica sol, and then spray-dried to make high-strength microspheres with ...

Embodiment 2

[0075] The operation steps are the same as in Example 1, except that the propylene epoxidation reaction temperature in the bubble column slurry bed reactor and the stirred tank slurry bed reactor is 80-90°C. After the reaction in the bubble column slurry bed reactor 1, the conversion rate of hydrogen peroxide in the raw material is ≥ 90%; after the reaction in the stirred tank slurry bed reactor 3 or the stirred tank slurry bed reactor II 4, the reaction product is The selectivity of oxypropylene is ≥91.5%, and the total conversion rate of hydrogen peroxide is ≥99%.

Embodiment 3

[0077] The operation steps are the same as in Example 1, except that the pressure of the propylene epoxidation reaction in the bubble column slurry bed reactor and the stirred tank slurry bed reactor is 0.11 MPa. After the reaction in the bubble column slurry bed reactor 1, the conversion rate of hydrogen peroxide in the raw material is ≥ 61%; after the reaction in the stirred tank slurry bed reactor 3 or the stirred tank slurry bed reactor II 4, the reaction product is The selectivity of oxypropylene is ≥98%, and the total conversion rate of hydrogen peroxide is ≥82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com