A steam cracking method

A technology of steam and cracking furnace, applied in the field of steam cracking, which can solve the problems of low thermal efficiency, high energy consumption and low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment is to illustrate adopting the method of the present invention to carry out steam cracking.

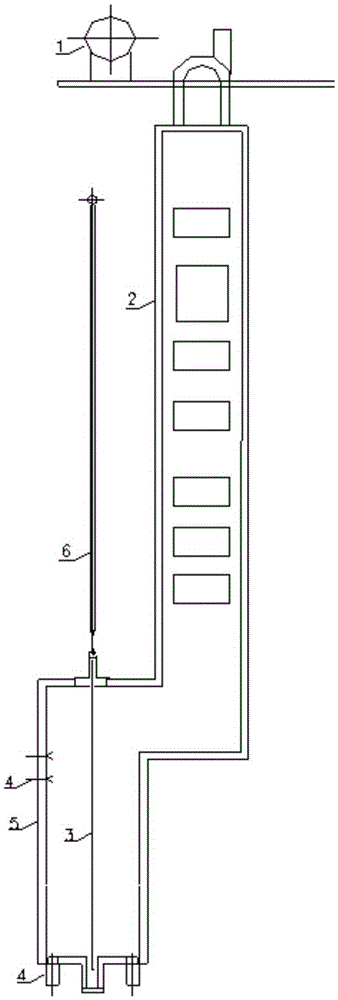

[0056] use figure 1 Shown steam cracking schematic diagram carries out cracking reaction, and concrete process comprises:

[0057] This method is implemented in the cracking furnace that contains blower fan 1 and quenching boiler 6, and described cracking furnace comprises convection section 2 and radiation section 5, and the cracking raw material naphtha of 60 ℃ enters after being vaporized and preheated through convection section 2 by convection section 2. The radiant furnace tube row 3 composed of two-pass radiant furnace tubes carries out the pyrolysis reaction, wherein the temperature at which naphtha is preheated in the convection section, that is, the crossover temperature (XOT) of the cracking furnace is 598°C, and the outlet temperature of the radiant section of the cracking furnace is 598°C. (COT) is 841°C;

[0058] Wherein, a radiant furnace tube row...

Embodiment 2

[0071] This embodiment is to illustrate adopting the method of the present invention to carry out steam cracking.

[0072] Steam cracking was carried out in the same manner as in Example 1.

[0073] The difference is:

[0074] The bottom burner supplies 80% of the total heat supply to the material in the tube row of the radiant furnace;

[0075] Oxygen-enriched air is used as the combustion-supporting gas, and the oxygen concentration contained in the oxygen-enriched air is 32% by volume (V / V).

Embodiment 3

[0086] This embodiment is to illustrate adopting the method of the present invention to carry out steam cracking.

[0087] Carry out steam cracking according to the same method as Example 1, the difference is that the bottom burner accounts for 85% of the total heat supply to the material in the tube row of the radiant furnace; oxygen-enriched air is used as the combustion-supporting gas, and The oxygen concentration contained in the oxygen-enriched air is 33% by volume (V / V);

[0088] Among them, the furnace tube in the radiant section adopts two-pass furnace tubes, and the first pass is two parallel vertical inlet pipes, and the second pass is a vertical outlet pipe, forming a 2-1 type radiant furnace tube, and the furnace tube The inlet diameter is 45mm, the outlet diameter of the furnace tube is 49.5mm, the length of the furnace tube is 12.8m, and the furnace tube adopts bottom-in and top-out; then the pyrolysis product is selectively collected through the quenching boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com