Fertilizer containing magnesium sulfate and preparation method thereof

A magnesium sulfate and fertilizer technology, applied in nitrate fertilizers, ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, etc., can solve problems such as eutrophication of water bodies, threats to human health, and loss of chemical fertilizers, so as to promote growth and effectively Conducive to the absorption of nutrients and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

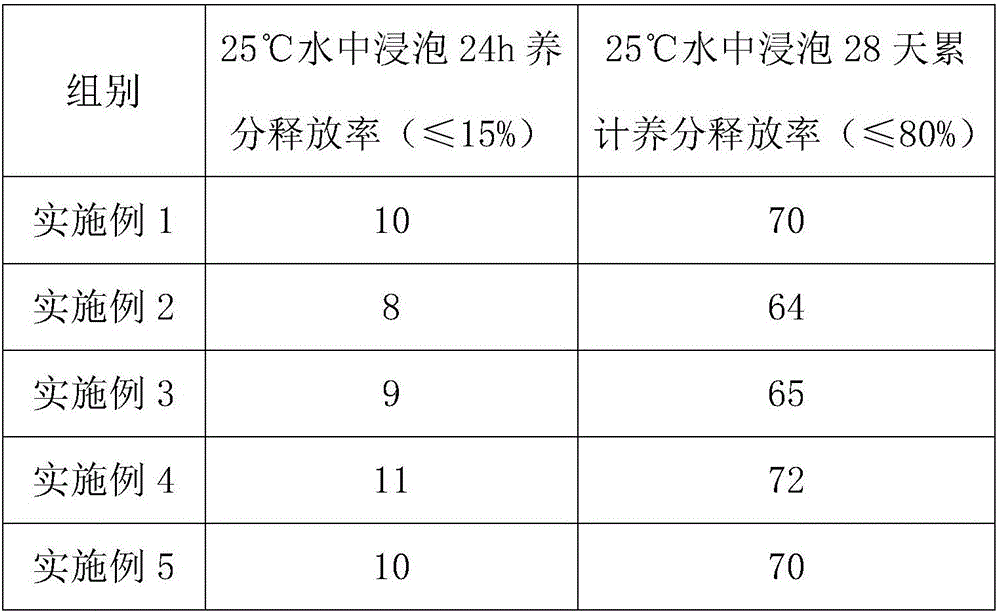

Examples

Embodiment 1

[0023] A kind of fertilizer containing magnesium sulfate, its raw material comprises by weight: 6.5 parts of urea, 25 parts of potassium nitrate, 12 parts of potassium monohydrogen phosphate, 13 parts of ammonium dihydrogen phosphate, 6.5 parts of diatomaceous earth, 0.2 part of potassium borate, sulfuric acid 0.4 parts of magnesium, 0.15 parts of calcium chloride, 0.15 parts of zinc sulfate, 0.4 parts of sodium molybdate, 5 parts of polyvinyl alcohol, 25 parts of soybean straw, 9 parts of soybean meal, 9 parts of cassava residue, 0.25 parts of EM bacterial agent, coating material 15 servings.

[0024] The preparation method of the above-mentioned magnesium sulfate-containing fertilizer may further comprise the steps:

[0025] S1. Mix soybean straw, soybean meal, and cassava residue evenly, sterilize, add EM bacterial agent aqueous solution, mix evenly, heat up to 36°C, keep warm for 50 days, dry, and pulverize to obtain organic fertilizer;

[0026] S2, take urea, spray atomi...

Embodiment 2

[0028] A kind of fertilizer containing magnesium sulfate, its raw material comprises by weight: 8 parts of 10 mesh urea, 20 parts of potassium nitrate, 15 parts of potassium monohydrogen phosphate, 10 parts of ammonium dihydrogen phosphate, 5 parts of 300 mesh diatomite, potassium borate 0.3 parts, 0.3 parts of magnesium sulfate, 0.2 parts of calcium chloride, 0.1 parts of zinc sulfate, 0.5 parts of sodium molybdate, 4 parts of polyvinyl alcohol, 30 parts of soybean straw, 8 parts of soybean meal, 10 parts of cassava dregs, 0.2 parts of EM bacterial agent , 12 parts of 150-mesh coating material;

[0029] Among them, during the preparation of the coating material, itaconic acid and acrylic acid were dissolved in water in a nitrogen atmosphere, the pH was adjusted to 7.5 with aqueous sodium hydroxide solution, and ammonium persulfate, N,N-methylenebispropylene Amide and humic acid were mixed evenly, then polyvinyl alcohol was added to mix evenly, the temperature was raised to 70...

Embodiment 3

[0034] A kind of fertilizer containing magnesium sulfate, its raw material comprises by weight: 5 parts of 20 mesh urea, 30 parts of potassium nitrate, 10 parts of potassium monohydrogen phosphate, 15 parts of ammonium dihydrogen phosphate, 8 parts of 200 mesh diatomite, potassium borate 0.1 part, 0.5 part of magnesium sulfate, 0.1 part of calcium chloride, 0.2 part of zinc sulfate, 0.3 part of sodium molybdate, 6 parts of polyvinyl alcohol, 20 parts of soybean straw, 10 parts of soybean meal, 8 parts of cassava residue, 0.3 part of EM bacterial agent , 18 parts of 100-mesh coating material;

[0035] Among them, during the preparation of the coating material, itaconic acid and acrylic acid are dissolved in water in a nitrogen atmosphere, the pH is adjusted to 6.5 with aqueous sodium hydroxide solution, and ammonium persulfate, N,N-methylenebispropylene Amide and humic acid were mixed evenly, then polyvinyl alcohol was added to mix evenly, the temperature was raised to 80°C, ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com