Low-cost ZBAN quaternary system fluoride optical glass and preparation method thereof

A technology of optical glass and fluoride, which is applied in the field of preparation of high-performance ZBAN system fluoride glass, can solve the problems of difficulty in preparing fluoride glass and high cost, achieve high efficiency of raw material allocation, reduce production cost, and reduce loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

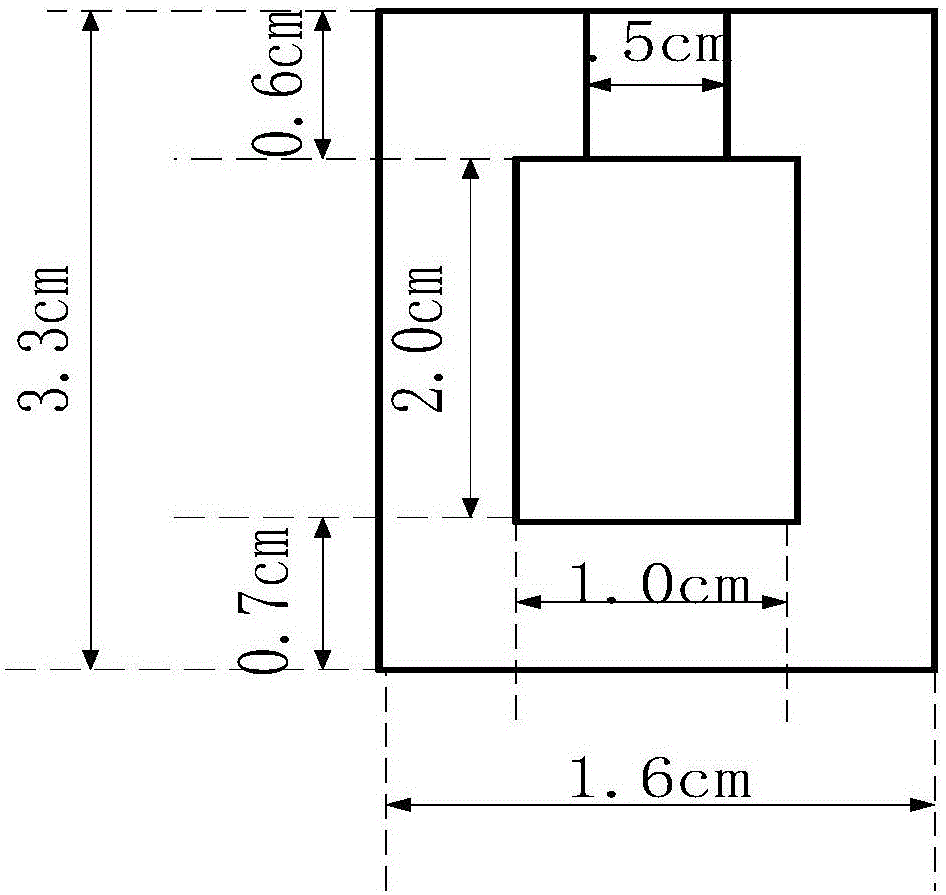

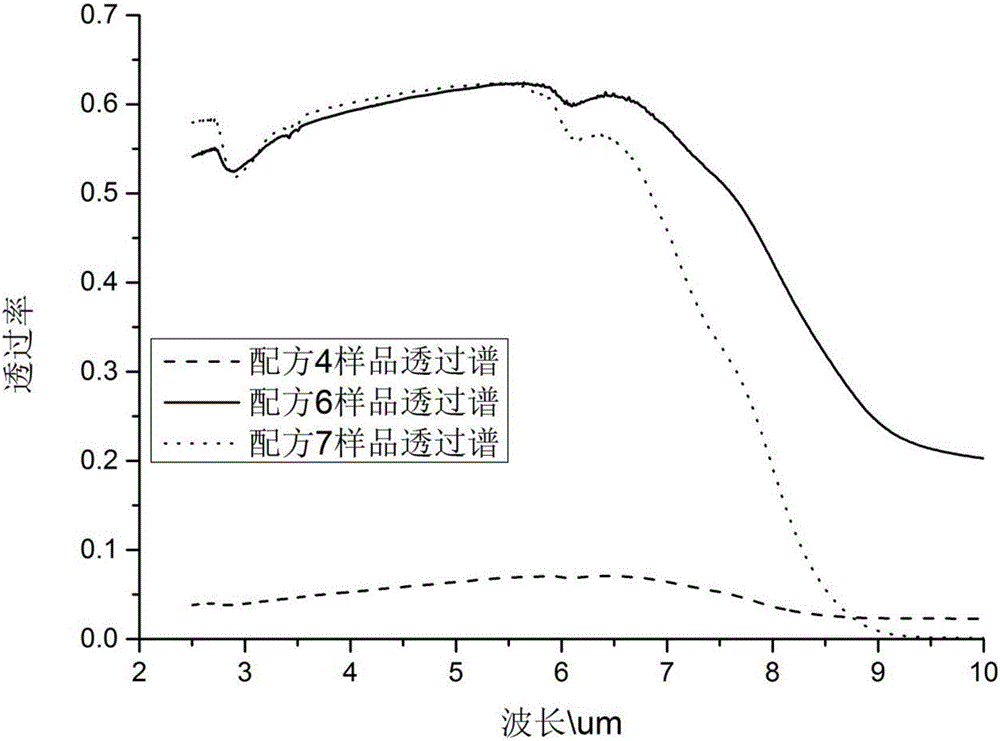

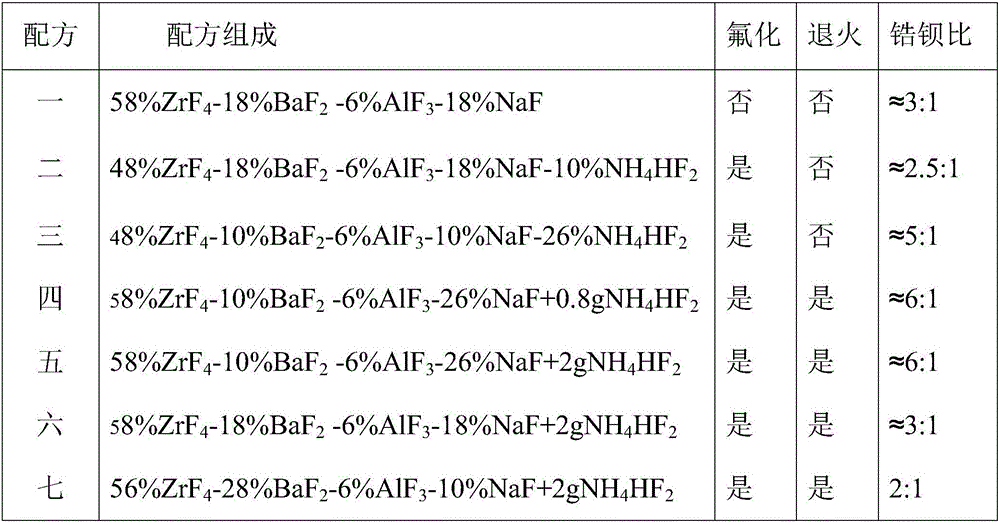

[0023] Effect of Raw Material Ratio on Glass Preparation.

[0024] For the quaternary fluoride system, zirconium fluoride and barium fluoride are the skeletons of the glass system, which directly determine whether a high-transparency bulk fluoride glass can be finally produced. Compared with formula five, the main change of formula six is to increase the molar ratio of zirconium fluoride and barium fluoride to 3:1. According to formula 6, a transparent glass sheet with a thickness of more than 5 mm was prepared for the first time. Experiments have proved that the fluoride system under this formula has strong glass-forming ability and low crystallinity. On the basis of formula six, the molar ratio of zirconium fluoride and barium fluoride was further lowered to 2:1, and formula seven was obtained, and a large piece of fluoride glass with a thickness of more than 5mm and good transparency was made again, and the formula was found The optical transparency and comprehensive mec...

Embodiment 2

[0031] Effect of fluorination treatment on glass preparation.

[0032] The melting process can be divided into two stages: no fluorination treatment and adding fluorination treatment during the melting process. The fluorination treatment is to add NH by 20%-40% of the total mass of raw materials when preparing raw materials 4 HF 2 , Let the raw materials stay in the low temperature zone (320-400 degrees) for 20-40 minutes, and then start to heat up and melt. Ammonium bifluoride decomposes in the low-temperature fluorination stage to produce ammonia and hydrogen fluoride. On the one hand, ammonia gas can take away oxygen and moisture in the crucible;

[0033] For the existing preparation process, generally by constructing a vacuum operation chamber or continuously passing NF 3 Such as auxiliary atmosphere to maintain an oxygen-free and dry environment during the fluoride glass melting process, which undoubtedly increases the cost of the experiment and the difficulty of opera...

Embodiment 3

[0036] Effect of annealing process on glass preparation.

[0037] The purpose of annealing is to improve the cracking of the cast glass and improve the transparency of the glass. The annealing process refers to preheating the metal mold in No. 2 muffle furnace before pouring the molten glass, the temperature is 100-250°C, and the preheating time is 10-30 minutes. When pouring, use the crucible tongs to take out the crucible in the No. 1 muffle furnace, open the crucible cover, pour the molten glass into the metal mold taken out of the No. 2 furnace, and then return the metal mold to 100-250 degrees In the No. 2 furnace, close the muffle furnace after heating for 30-100 minutes, and let it cool down to room temperature naturally.

[0038] The glass raw material was prepared according to formula 4, and after the melting and annealing process, small glass pieces were successfully obtained; the reason why the glass was not fully formed was due to insufficient annealing time, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com