Hydrogen sulfide vanadium removal technology

A hydrogen sulfide and process technology, applied in hydrogen sulfide, titanium halide, titanium tetrachloride and other directions, can solve the problems of high vanadium removal cost, unfavorable reaction, large amount of residue, etc., to reduce equipment and raw material costs, increase gas-liquid The effect of contacting surfaces and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

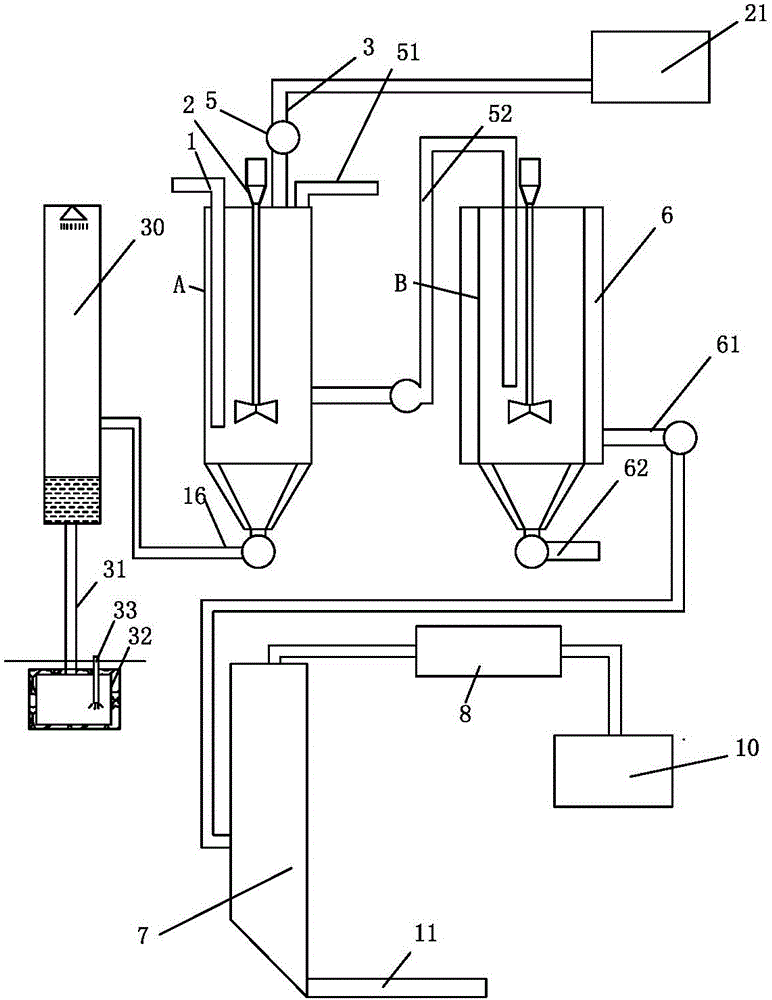

[0025] Embodiment 1: a kind of hydrogen sulfide removes vanadium process, and process step is as follows:

[0026] 1) Through crude TiCl 4 Feed pipe 51 transports crude titanium tetrachloride to reactor A, which accounts for about 70% of the volume of the reactor. The feed rate is controlled by controlling the liquid level of the reactor and the feed valve, and the feed rate is 2.5 tons / hour;

[0027] 2) Start the agitator 2 of the reactor A, and directly feed hydrogen sulfide gas and nitrogen gas into the reactor A, the hydrogen sulfide gas: crude titanium tetrachloride mass ratio is 1: 1000; by adjusting the negative pressure pipeline valve at the top of the reactor , control reactor A normal pressure reaction, hydrogen sulfide gas and crude TiCl 4 Medium VOCl 3 , ferric chloride, magnesium chloride, chromium chloride high-boiling-point impurities react to obtain the slurry-like object to be discharged from the bottom of the reactor, the discharge speed is 0.05 tons / hour, ...

Embodiment 2

[0030] Embodiment 2: a kind of hydrogen sulfide removes vanadium process, and process step is as follows:

[0031] 1) Through crude TiCl 4 The feed pipe transports crude titanium tetrachloride to the reactor A, accounting for about 80% of the volume of the reactor, and the feed rate is controlled by controlling the liquid level of the reactor and the feed valve, and the feed rate is 3.0 tons / hour;

[0032] 2) Start the agitator 2 of the reactor A, and directly feed hydrogen sulfide gas and nitrogen gas into the reactor A, the mass ratio of hydrogen sulfide gas: crude titanium tetrachloride is 2: 1000; by adjusting the negative pressure pipeline valve at the top of the reactor , control reactor A normal pressure reaction, hydrogen sulfide gas and crude TiCl 4 Medium VOCl 3 , ferric chloride, magnesium chloride, chromium chloride high-boiling impurity reaction to obtain muddy objects from the reactor bottom discharge, discharge speed 0.1 tons / hour, every 1 hour mud 1 time, m...

Embodiment 3

[0035] Embodiment 3. A hydrogen sulfide vanadium removal process, the process steps are as follows:

[0036] 1) Through crude TiCl 4 The feed pipe transports crude titanium tetrachloride to the reactor A, accounting for about 75% of the volume of the reactor, and the feed rate is controlled by controlling the liquid level of the reactor and the feed valve, and the feed rate is 2.8 tons / hour;

[0037] 2) Start the agitator 2 of the reactor A, and directly feed hydrogen sulfide gas and nitrogen gas into the reactor A, the hydrogen sulfide gas: crude titanium tetrachloride mass ratio is 1.5: 1000; by adjusting the negative pressure pipeline valve at the top of the reactor , control reactor A normal pressure reaction, hydrogen sulfide gas and crude TiCl 4 Medium VOCl 3 , ferric chloride, magnesium chloride, chromium chloride high-boiling impurity reaction obtains the mud-like object and is discharged from the reactor bottom, and the discharge speed is 0.08 tons / hour, and every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com