Self-heating type reactor used for hydrogen production by reforming and filled with high-temperature phase-change material

A high-temperature phase change and reforming hydrogen production technology, which is applied in the direction of hydrogen, hydrogen/synthesis gas production, chemical instruments and methods, etc., can solve the problems of catalyst sintering, hydrogen production performance degradation, side reaction enhancement, etc., to improve hydrogen production performance, suppression of excessive temperature, and reduction of carbon monoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

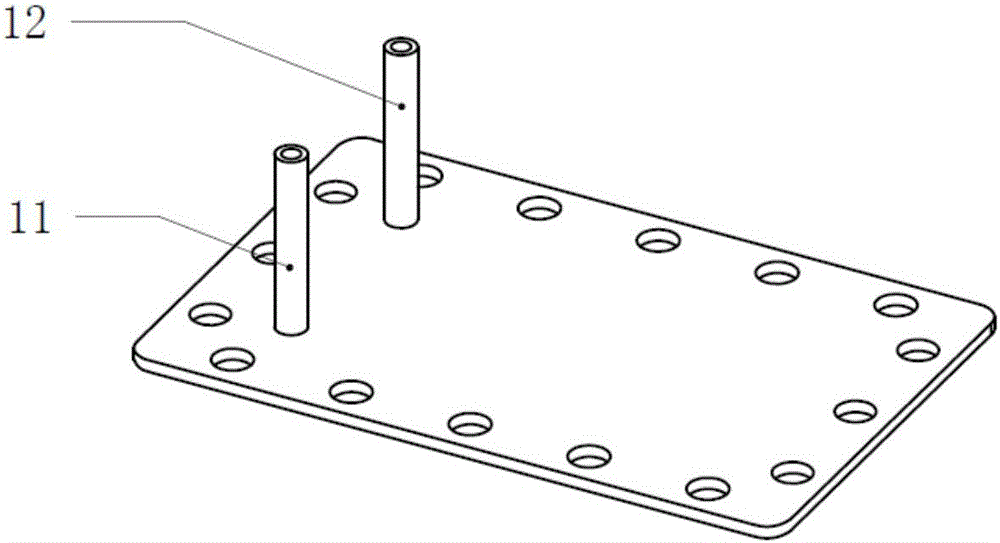

[0037] Such as figure 1 , figure 2 , Figure 11As shown, the reactor of the present invention is from top to bottom, and the upper surface is provided with the upper cover plate 1, the first graphite gasket, Upper evaporating plate 2, second graphite gasket, lower evaporating plate 3, third graphite gasket, methanol reforming hydrogen production heat absorbing plate 4 filled with high temperature phase change material on the lower surface, sealing plate 6, fourth graphite gasket , the methanol catalytic combustion plate 7 filled with high-temperature phase change material on the lower surface, the fifth graphite gasket and the lower cover plate 8 with the reformed gas outlet pipe 31 and the combustion exhaust outlet pipe 32 connected on the lower surface.

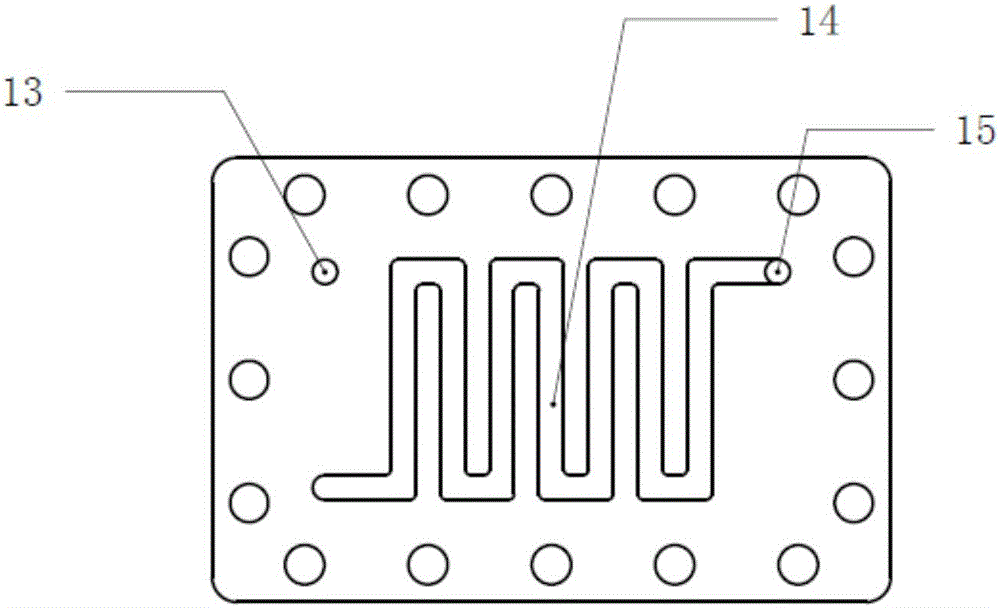

[0038] Such as image 3 , Figure 4 As shown, the upper surface of the upper evaporating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com