Manufacturing method of halogen-free, phosphorus-free, environment-friendly and flame-retardant paper-based copper clad laminate

A flame-retardant, copper-clad laminate technology, applied in chemical instruments and methods, paper/cardboard layered products, adhesive types, etc., can solve problems such as environmental pollution, high prices of phosphorus-containing compounds, and copper-clad laminates are susceptible to moisture, etc. Achieving the effect of cost reduction and heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

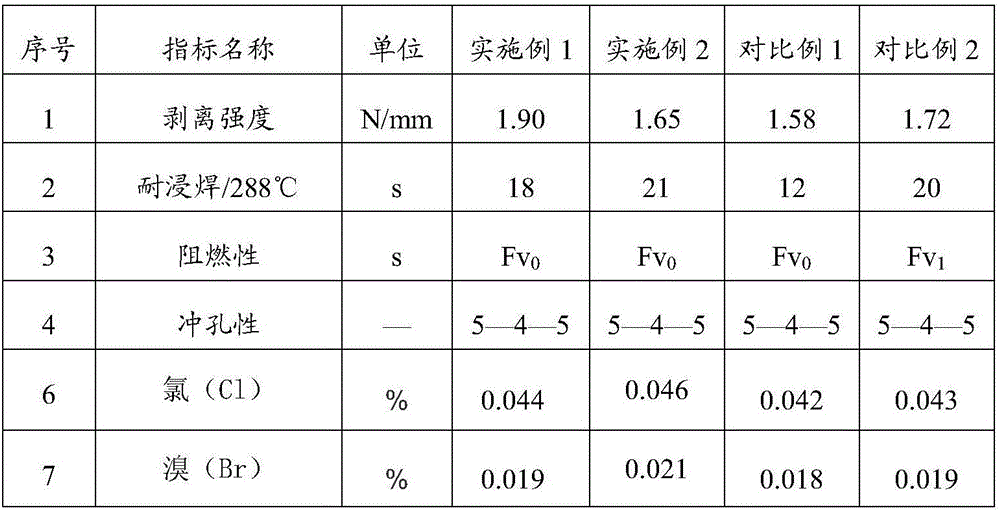

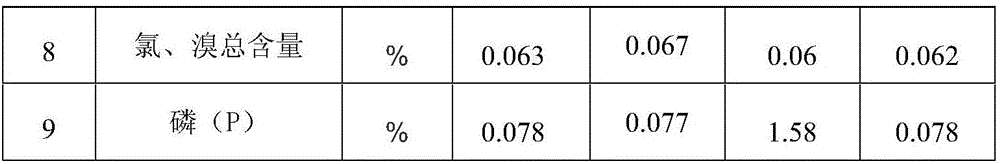

Examples

Embodiment 1

[0023] A method for preparing a halogen-free, phosphorus-free, environmentally friendly flame-retardant paper-based copper-clad laminate, the steps are as follows:

[0024] (1) Preparation of nitrogen-containing phenolic resin A: 20 parts of urea, 140 parts of melamine and 300 parts of concentration of 37wt% formaldehyde solution are dropped into the reactor successively, then adding 1 part of concentration is 25wt% sodium hydroxide solution, at 90 After reacting for 50 minutes under the condition of ℃, continue to add 70 parts of methanol with a concentration of 98%, and cool down to 45 ℃ to prepare a nitrogen-containing phenolic resin A with a nitrogen content of 20%.

[0025] (2) Preparation of nitrogen-containing phenolic resin B: 100 parts of phenol, 200 parts of 2,4-diamino-6-phenyl-1,3,5-triazine and 300 parts of formaldehyde solution with a concentration of 37 wt% were put into the reactor , then add 10 parts of oxalic acid aqueous solution with a concentration of 10%,...

Embodiment 2

[0031] A method for preparing a halogen-free, phosphorus-free, environmentally friendly flame-retardant paper-based copper-clad laminate, the steps are as follows:

[0032] (1) Preparation of nitrogen-containing phenolic resin A: 50 parts of urea, 260 parts of melamine and 500 parts of concentration of 37wt% formaldehyde solution are dropped into the reactor successively, then adding 3 parts of concentration is 25wt% Sodium hydroxide solution, at 100 After reacting at ℃ for 70 minutes, continue to add 100 parts of methanol with a concentration of 98%, and cool down to 15℃ to prepare nitrogen-containing phenolic resin A with a nitrogen content of 35%.

[0033] (2) Preparation of nitrogen-containing phenolic resin B: 150 parts of phenol, 300 parts of 2,4-diamino-6-phenyl-1,3,5-triazine and 500 parts of formaldehyde solution with a concentration of 37 wt% were put into the reactor , then add 10 parts of oxalic acid aqueous solution with a concentration of 15%, and react at 100°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com