Manufacturing method of waste laminated wood

A manufacturing method and glulam technology, which are applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, can solve the problems of secondary pollution, high cost, and excessive rubber materials, and achieve increased fastening capacity and reduced The effect of increasing the amount of glue and the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The glue that present embodiment uses is made up of each component of following percentage by weight: 40% sodium silicate, 15% polyvinyl acetate, 20% polyvinyl alcohol, 15% acrylic resin, 5% pine oil and 5% sandalwood leaf powder.

[0031] The processing steps of the glulam in this embodiment are as follows:

[0032] (1) Select the wood waste after the eucalyptus processing board to process, the selected waste guarantees no rot, no insects, no cracked wood, the wood waste is put into a drying kiln with a temperature of 55°C for drying, and it is dried to Stop drying when the moisture content of the wood is 8%;

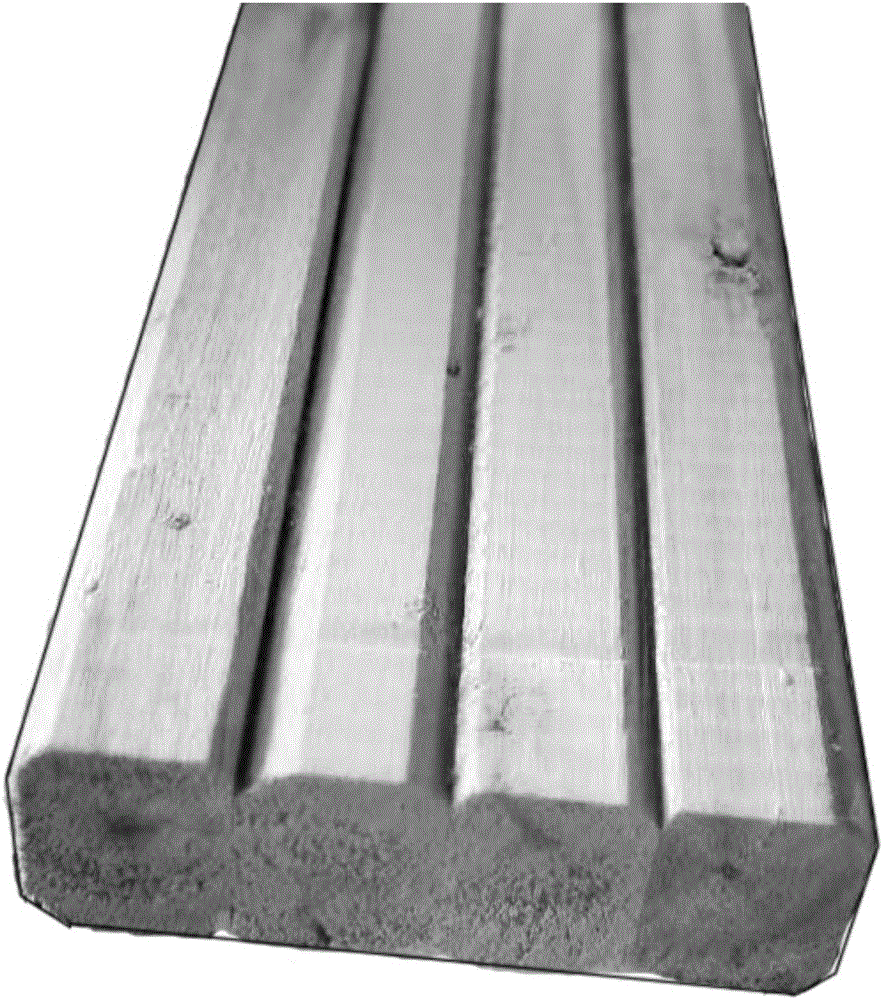

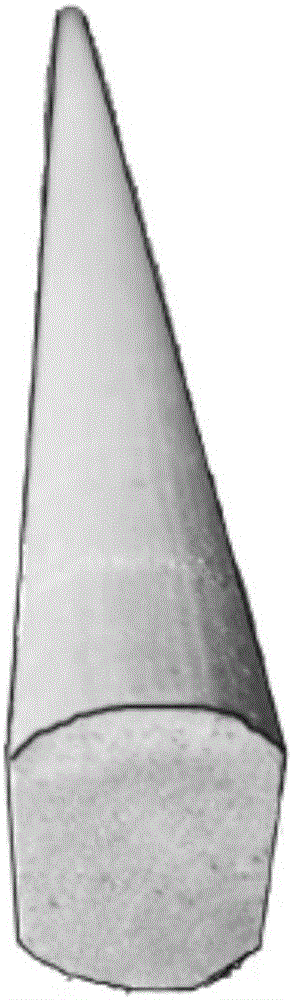

[0033] (2) Process the wood waste after stocking into a small round wooden stick, and then carry out molding to obtain a modeling wooden stick. Corresponding to two rectangular surfaces, the length of the small round wooden stick is 20cm, the diameter is 2cm, and the width of the rectangular surface is 1cm;

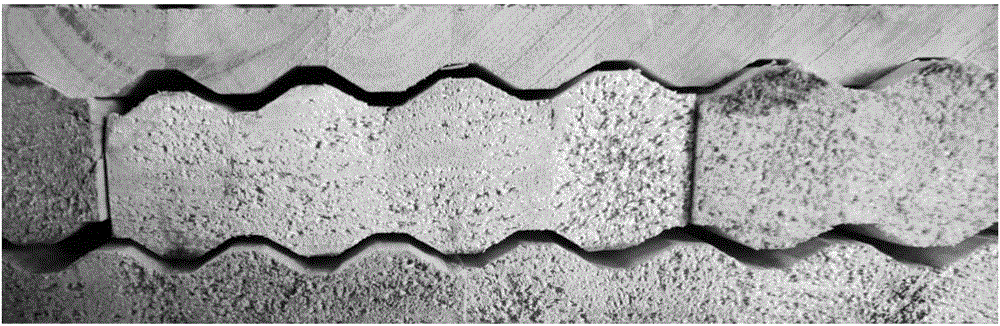

[0034] (3) Splicing and grooving a plurality of mo...

Embodiment 2

[0037] The glue that present embodiment uses is made up of each component of following percentage by weight: 38% sodium silicate, 10% polyvinyl acetate, 18% polyvinyl alcohol, 14% acrylic resin, 10% pine oil and 10% sandalwood leaf powder.

[0038] The processing steps of the glulam in this embodiment are as follows:

[0039] (1) Select the wood waste after the eucalyptus processing board to process, the selected waste guarantees no rot, no insects, no cracked wood, put the wood waste into a drying kiln with a temperature of 80°C for drying, and dry to Stop drying when the moisture content of the wood is 12%;

[0040](2) Process the wood waste after stocking into a small round wooden stick, and then carry out molding to obtain a modeling wooden stick. Corresponding to two rectangular surfaces, the length of the small round wooden stick is 30cm, the diameter is 6cm, and the width of the rectangular surface is not less than 5.5cm;

[0041] (3) Splicing and grooving a pluralit...

Embodiment 3

[0044] The glue that present embodiment uses is made up of each component of following percentage by weight: 50% sodium silicate, 12% polyvinyl acetate, 15% polyvinyl alcohol, 5% acrylic resin, 9% pine oil and 9% sandalwood leaf powder.

[0045] The processing steps of the glulam in this embodiment are as follows:

[0046] (1) Select the wood waste after the eucalyptus processing board to process, the selected waste guarantees no rot, no insects, no cracked wood, the wood waste is put into a drying kiln with a temperature of 60°C for drying, and it is dried to Stop drying when the moisture content of the wood is 11%;

[0047] (2) Process the wood waste after stocking into a small round wooden stick, and then carry out molding to obtain a modeling wooden stick. Corresponding to two rectangular surfaces, the length of the small round wooden stick is 50cm, the diameter is 3cm, and the width of the rectangular surface is 1.5cm;

[0048] (3) Splicing and grooving a plurality of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com