A kind of preparation method of metal molybdenum nano sheet

A nanosheet and metal technology, which is applied in the field of preparation of metal molybdenum nanosheets, can solve the problems of limiting the large-scale production of nanostructured materials, requiring high control precision of growth parameters and poor reproducibility, and meeting the requirements of short preparation period and preparation environment. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

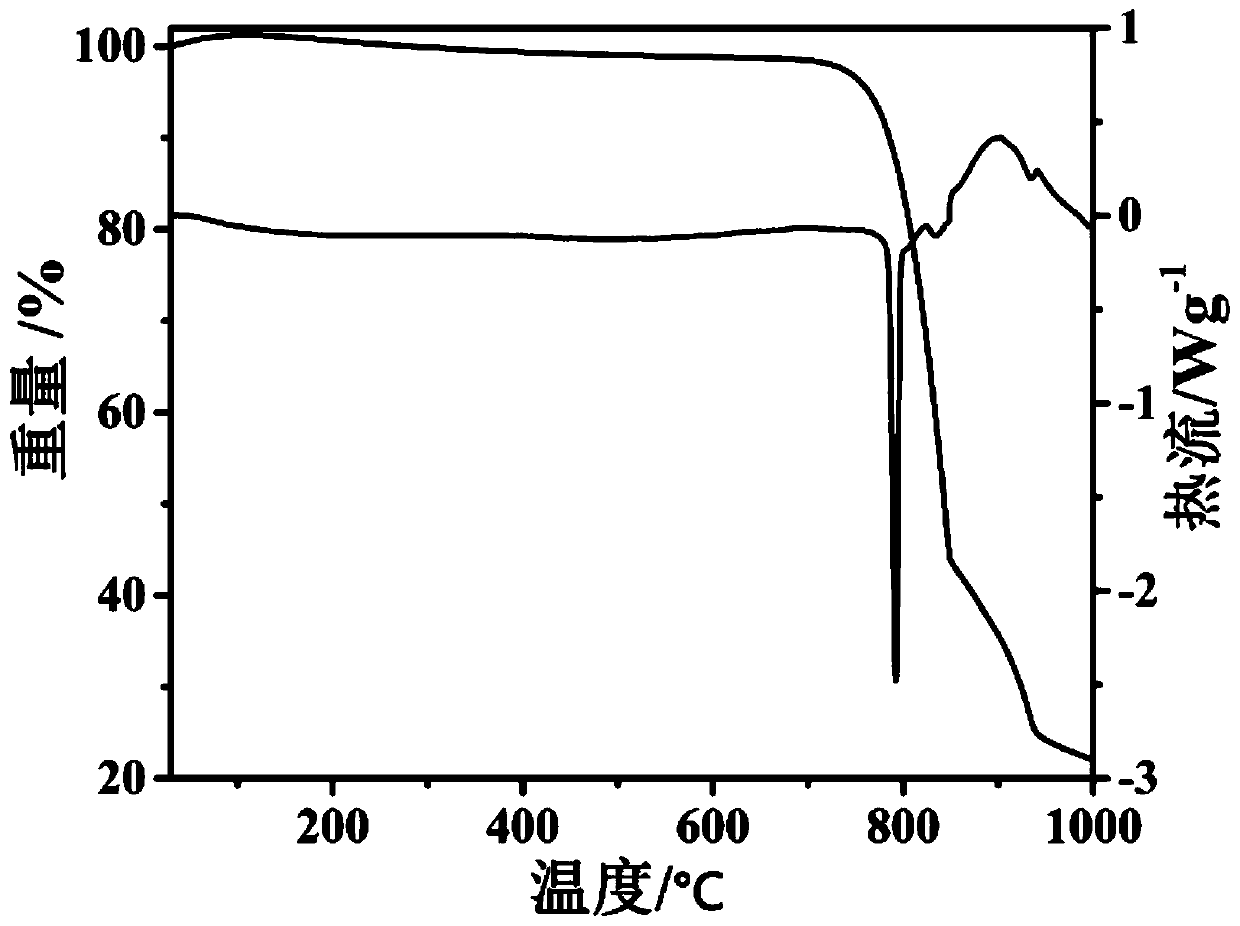

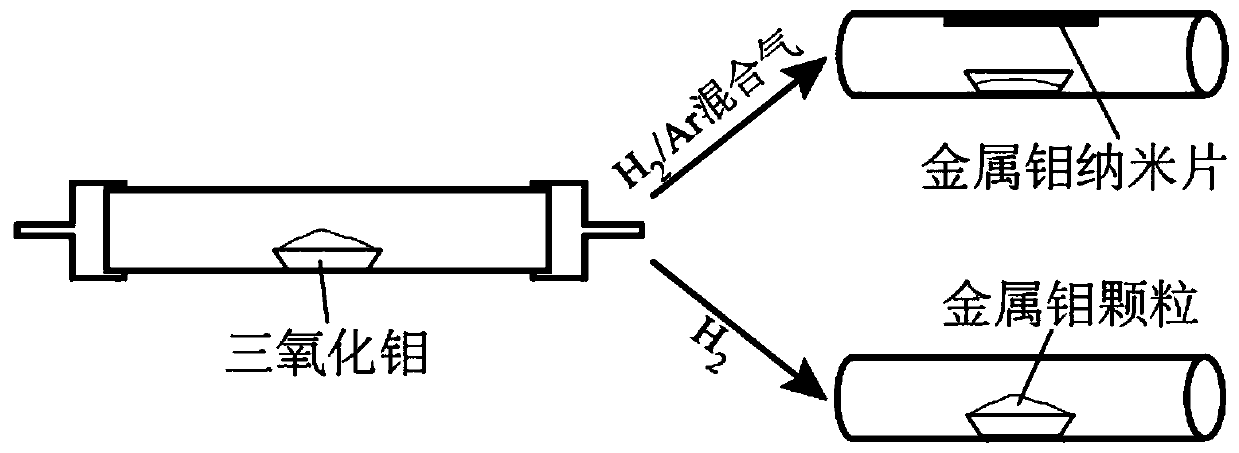

[0032] use as figure 1 The thermogravimetric-differential thermal analysis curve of shown molybdenum trioxide, analyze the sublimation law of molybdenum trioxide; And adopt image 3 The schematic diagram of the process flow is shown for the preparation of metallic molybdenum nanosheets.

[0033] Put the molybdenum trioxide powder without any treatment in the porcelain boat, put the porcelain boat into the quartz tube in the effective heating area of the tube furnace, use the vacuum pump to exhaust the air in the quartz tube, and then inject 10vol%H 2 / Ar gas, 10vol% H during heating 2 / Ar gas flow rate is maintained at 10 sccm, and the heating rate is controlled at 20°C / min;

[0034] When the temperature of the tube furnace reaches 900°C, adjust the flow of 10vol%H 2 The amount of / Ar is a flow rate of 100 sccm, heat preservation for 2 hours, and cool to room temperature after the reaction to obtain metal molybdenum nanosheets.

[0035] By XRD results ( Figure 4 ) char...

Embodiment 2

[0040] Molybdenum nanosheets prepared according to the method in Example 1. The difference is that the reaction temperature is 790°C, and when the temperature of the tube furnace reaches 790°C, 10vol%H 2 The flow rate of / Ar is 100sccm, and after the reaction, the tube furnace is closed and cooled to room temperature to obtain metallic molybdenum nanosheets.

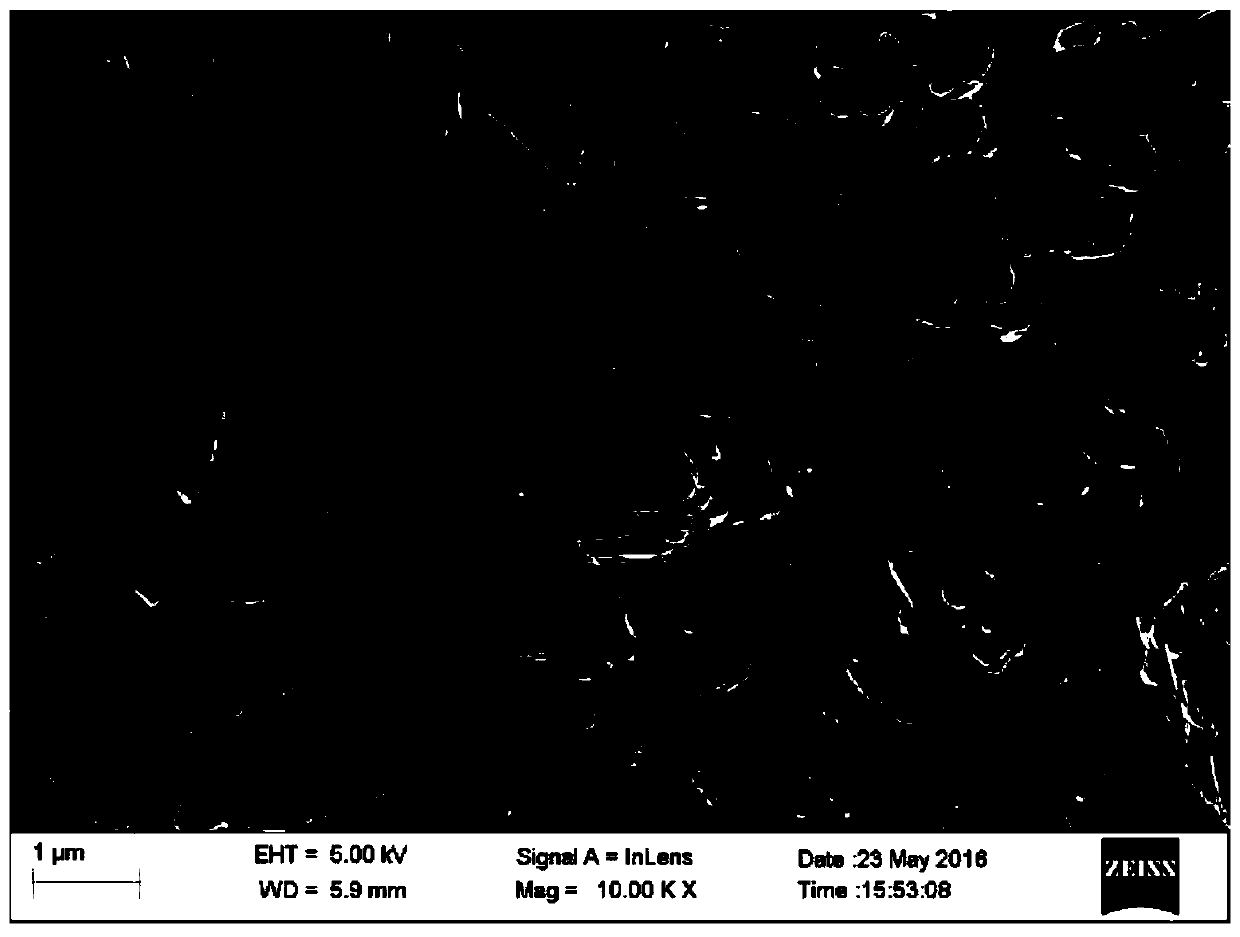

[0041] The product obtained in this embodiment is similar to the result of Example 1, and the metal molybdenum nanosheets have also grown; the SEM image of the prepared metal molybdenum nanosheets is as follows Figure 10 , microscopically, the size is uniform and the size is 0.1~2μm, the thickness is <100nm, and the edge has a large number of dendritic structures.

Embodiment 3

[0043] Molybdenum nanosheets prepared according to the method in Example 1. The difference is that the reaction temperature is 1000°C, when the temperature of the tube furnace reaches 1000°C, adjust the flow of 10vol%H 2 The flow rate of / Ar is 100sccm, and after the reaction, the tube furnace is closed and cooled to room temperature to obtain metallic molybdenum nanosheets.

[0044] The product obtained in this embodiment is similar to the result of Example 1, and the metal molybdenum nanosheets have also grown; the SEM image of the obtained metal molybdenum nanosheets is as follows Figure 11 As shown, it is packed and fluffy sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com