Ore dressing method of copper-cobalt ores

A beneficiation method, copper-cobalt technology, applied in the direction of chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of reducing the recovery rate of other valuable metals, waste of resources, low metal recovery rate, etc., and achieve the improvement of copper-cobalt Sorting efficiency, strong ore adaptability and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

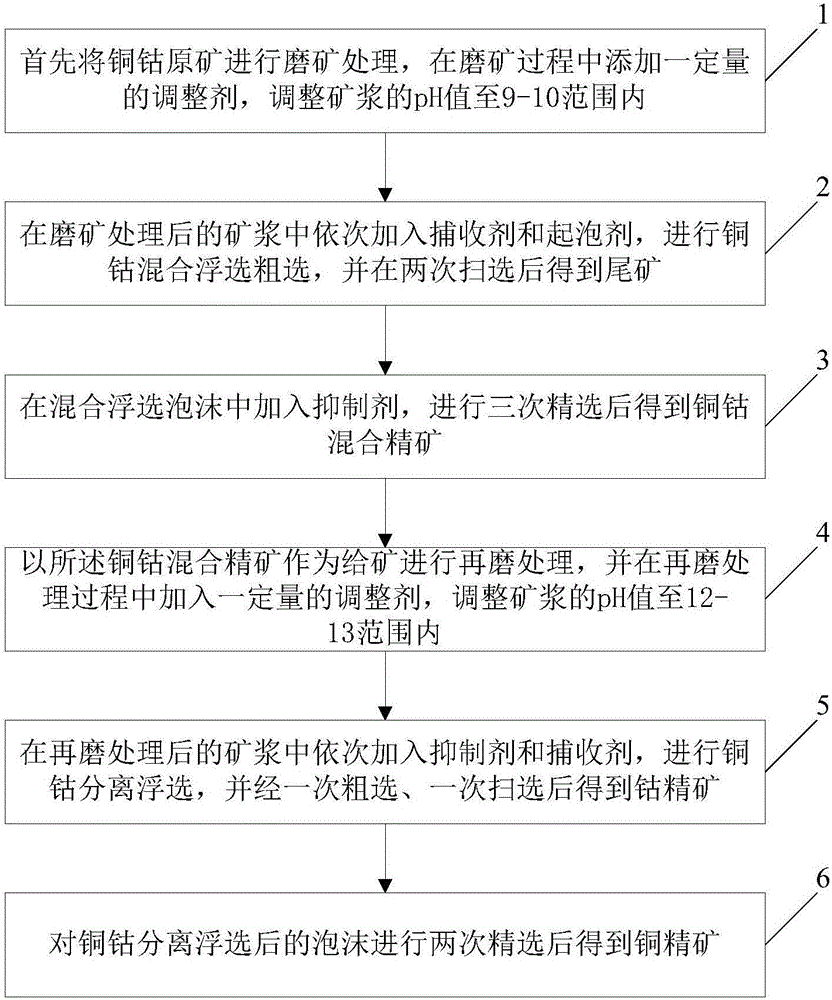

Image

Examples

Embodiment 1

[0042] Example 1. The raw ore copper grade of a copper-cobalt ore is 1.56%, and the cobalt grade is 0.12%. The process mineralogy research shows that the copper-containing minerals in this ore are mainly chalcopyrite and bornite, and the cobalt-containing minerals are mainly sulfur-copper-cobalt ore. And pyrite containing cobalt.

[0043] The ore is ground with a wet ball mill, and the particle size of the ground product is -0.074mm, accounting for 65%. Lime is added during the grinding process, and the pH value of the slurry is adjusted to 9.6. The combination of butyl xanthate and butylammonium black medicine is used as the collection The mixed flotation of copper and cobalt is carried out with terpineol oil as a foaming agent. The mixed flotation includes one roughing, two sweeping and three refining. The amount of roughing collector is 80g / t, and the amount of foaming agent is 20g / t. t, the amount of agent used for sweeping is gradually reduced to one-third of that of roug...

Embodiment 2

[0047]Example 2, the raw ore copper grade of a copper-cobalt ore is 1.62%, and the cobalt grade is 0.13%. The process mineralogy research shows that the copper-containing minerals in the ore are mainly chalcopyrite, accompanied by a small amount of bornite and chalcocite, etc., containing Cobalt minerals are mainly sulfur-copper-cobalt ore.

[0048] The ore is ground by a wet ball mill, and the particle size of the ground product is -0.074mm, accounting for 65%. Lime is added during the grinding process, and the pH value of the slurry is adjusted to 9.5. The combination of butyl xanthate and butylammonium black medicine is used as a collection The mixed flotation of copper and cobalt is carried out with terpineol oil as a foaming agent. The mixed flotation includes one roughing, two sweeping and three refining. The amount of roughing collector is 80g / t, and the amount of foaming agent is 20g / t. t, the amount of agent used for sweeping is gradually reduced to one-third of that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com