Composite isolation membrane for lithium-ion battery and preparation method of composite isolation membrane

A lithium-ion battery, separator technology, applied in secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc., can solve the problems of low porosity, poor safety, low melting point, etc. High liquid absorption rate, high liquid retention rate, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

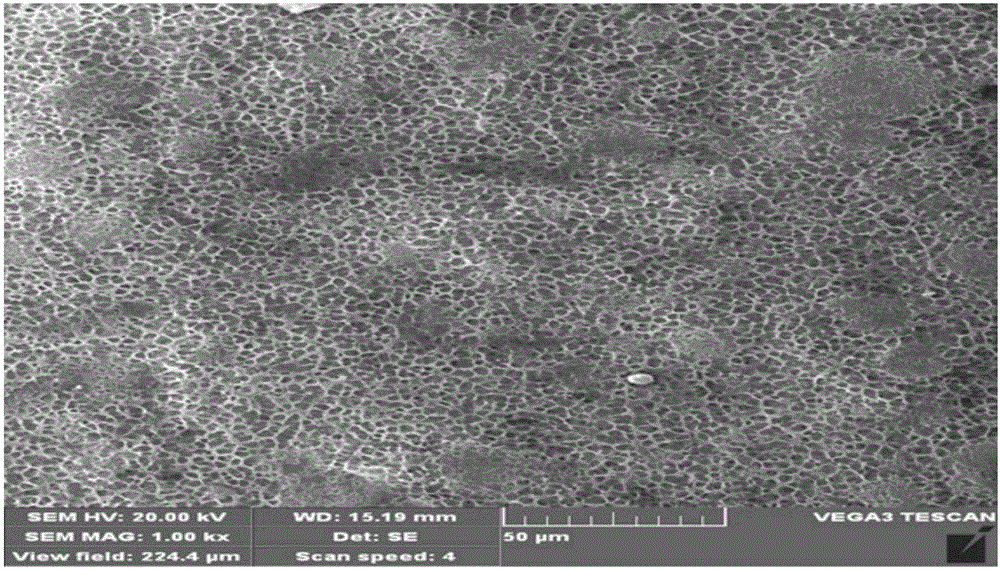

[0033] Composite diaphragm for batteries, a film layer with a thickness of 40 μm is prepared by the wet roller scraping continuous coating method from the slurry, and the slurry includes the following components: 70% polyvinylidene fluoride, 5% coupling agent, plasticizer 8% agent, 17% skeleton filler, among which vinyl trisilane is used as coupling agent, dibutyl phthalate or dioctyl phthalate is used as plasticizer, and silica is used as skeleton filler. After the parts are taken according to the proportion, they are prepared sequentially through vacuum slurry, and after wet roller brushing to prepare a film, a film layer with a thickness of 40 μm is obtained, and the obtained film layer is laminated with the positive and negative plates of the lithium-ion battery to form Battery unit, the battery unit is placed in a three-stage phase separation device for extraction, the extraction agent is methanol, the extraction temperature is 40°C, the vacuum degree of the extraction cha...

Embodiment 2

[0035] The components are taken according to the following proportions: polyvinylidene fluoride 70%, the inorganic filler of the skeleton is SiO2 17%, dibutyl phthalate 8%, vinyltrisilane 5% and formed after mixing and roller scraping coating. film, film thickness m. The separator and the positive and negative electrodes are laminated in the order of negative electrode-diaphragm-positive electrode (double-sided)-diaphragm-negative electrode to form a battery unit. The battery unit is placed in a three-stage phase separation device for extraction to form a porous structure. Methanol is used as the extraction agent, the temperature is controlled at 40°C, the system maintains a vacuum of -0.06MPa, and the microwave vibration frequency is 30-40Hz. Phase separation was achieved through primary, secondary, and tertiary extractions, respectively. The concentration of extractant in the primary solvent chamber is 91%, and the phase separation time is 45min; the concentration of extrac...

Embodiment 3

[0037]Composite diaphragm for batteries, a film layer with a thickness of 80 μm is prepared by the wet roller scraping continuous coating method from the slurry, and the slurry includes the following components: 70% polyvinylidene fluoride, 5% coupling agent, plasticizer 8% agent, 17% skeleton filler, among which vinyl trisilane is used as coupling agent, dibutyl phthalate or dioctyl phthalate is used as plasticizer, and silica is used as skeleton filler. After the parts are taken according to the proportion, they are prepared sequentially through vacuum slurry, and after wet roller brushing to prepare a film, a film layer with a thickness of 40 μm is obtained, and the obtained film layer is laminated with the positive and negative plates of the lithium-ion battery to form Battery unit, the battery unit is placed in a three-stage phase separation device for extraction, the extraction agent is methanol, the extraction temperature is 40°C, the vacuum degree of the extraction cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com