Preparation method for aryl substituted p-phenylenediamine substance

A technology of p-phenylenediamines and aryl groups, which is applied in the field of preparation of aryl-substituted p-phenylenediamines, and can solve the problems of high cost, strong corrosion, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

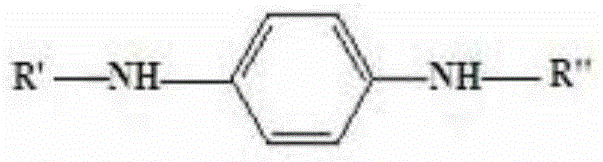

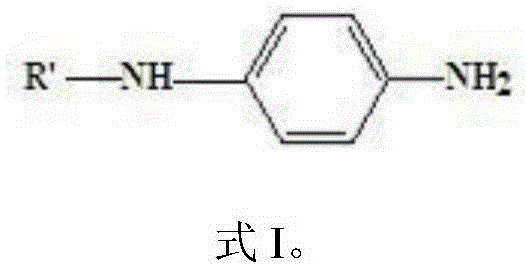

[0028] The preparation method comprises: reacting raw material A and raw material B under the action of a hydrogen acceptor and a catalyst to form aryl-substituted p-phenylenediamine substances; raw material A has the structure shown in formula I, and raw material B is cyclohexanone and / or Or o-methylcyclohexanone, the hydrogen acceptor is a hydrogen acceptor that can be converted into raw material B by hydrogen;

[0029]

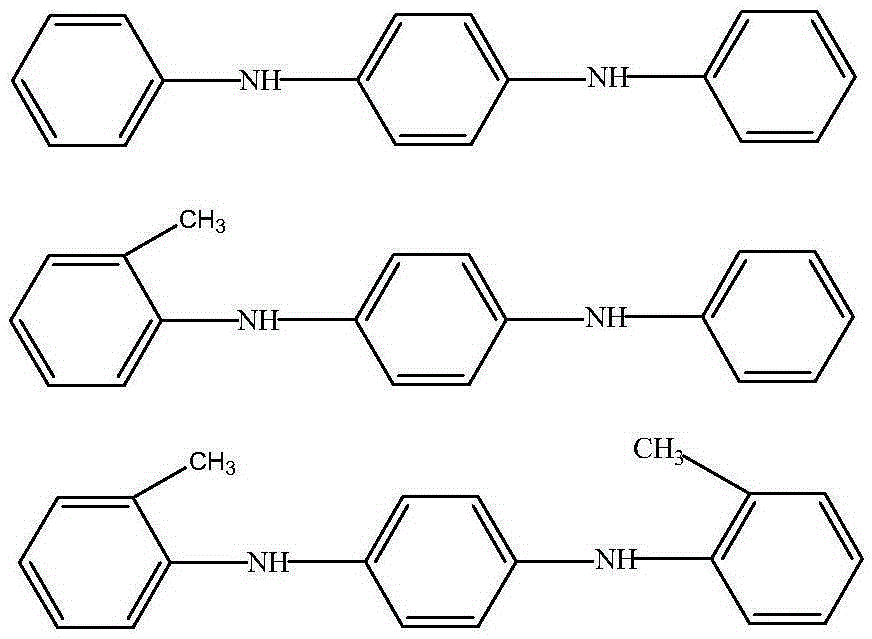

[0030] The above preparation method provided by the present invention reacts raw material A having the structure of formula I with raw material B (cyclohexanone and / or o-methylcyclohexanone) to generate aryl-substituted p-phenylenediamines. Specifically, both cyclohexanone and o-methylcyclohexanone can undergo a dehydrogenation reaction under the action of a catalyst, and at the same time replace a hydrogen atom on the amino group at the N' position in the raw material A, forming R" as phenyl or o-methyl The aryl group of phenyl is substituted p-phenylen...

Embodiment 1

[0043] Into a 500 mL autoclave were added 36.8 g (0.2 mol) of N-phenyl-p-phenylenediamine, 94.1 g (1 mol) of phenol, 2.0 g (0.02 mol) of cyclohexanone and 1.3 g of dry Pd / C (containing 5 wt% Pd) Catalyst; start stirring, replace with nitrogen for 3 times, then heat up to 220°C, keep warm for 6 hours, then cool down to room temperature and discharge, filter and recover the catalyst, distill the filtrate under reduced pressure to remove unreacted phenol and cyclohexanone, and obtain a distillation raffinate of 51.7 g, the content of N,N'-diphenyl-p-phenylenediamine was 94.1% as measured by sampling, and the calculated yield was 93.6%.

Embodiment 2 to 5

[0045] Using the same raw materials and process conditions as in Example 1 to prepare N,N'-diphenyl-p-phenylenediamine, the difference is that the relationship between the amount of each raw material is different (wherein the amount of N-phenyl-p-phenylenediamine is kept weight unchanged). Concrete dosage relation and product situation are as follows:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com