GTO catalyst used for fluidized bed and preparation method of GTO catalyst

A catalyst and fluidized bed technology, applied in the field of GTO catalyst and its preparation, can solve the problems of rapid reaction heat removal, easy to fly temperature, and low temperature olefin weight selectivity that is not easy to fly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

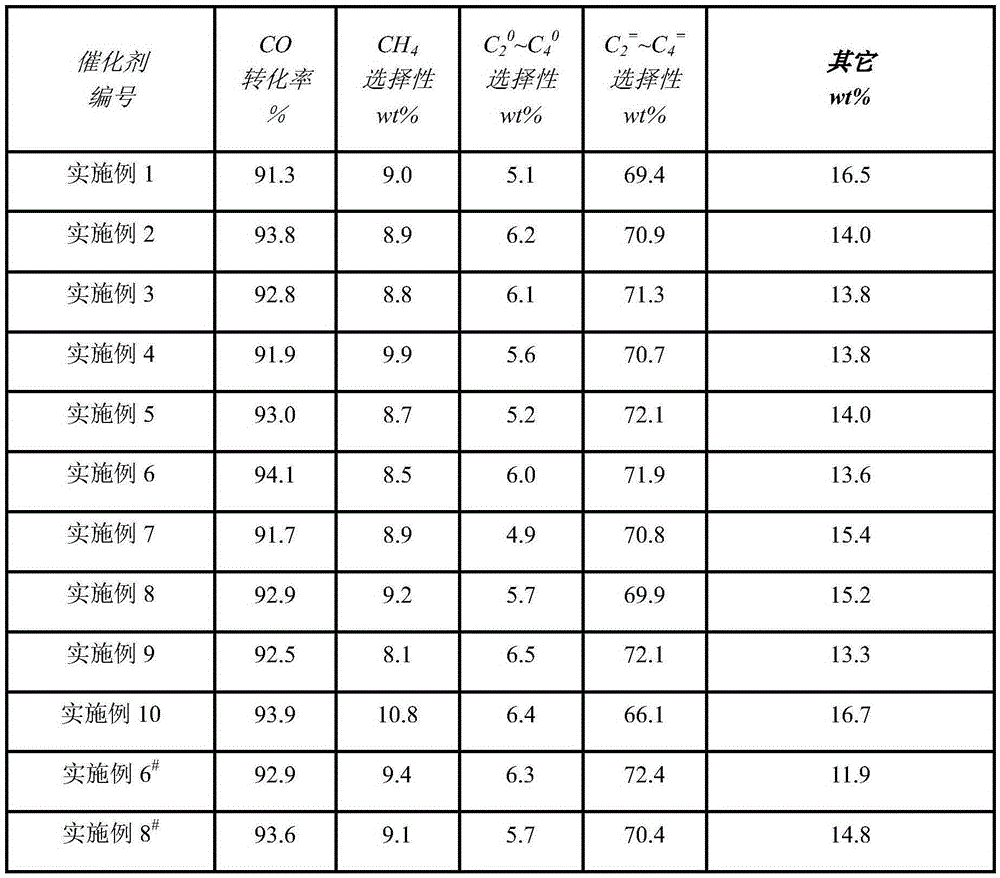

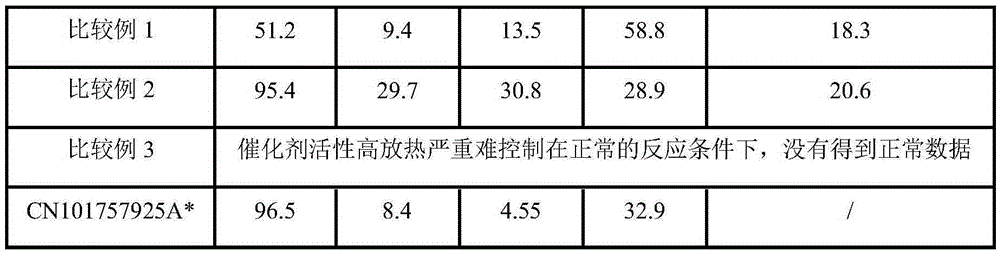

Examples

Embodiment 1

[0033] Get 606.03g iron nitrate nonahydrate and dissolve in water to make solution I; 2.23g zinc nitrate hexahydrate and 313.3g gallium nitrate nonahydrate are dissolved in water to make a solution, and then the solution is mixed with 6% by weight of ammonia solution of 700g Flow precipitation, filter the precipitation, and wash repeatedly with deionized water to obtain fresh and clean mixed oxide II of zinc oxide and gallium oxide, mix solution I and mixed oxide II to obtain slurry III; 5.31g weight content 40% ZrO 2 The sol, 0.35g calcium nitrate tetrahydrate and 0.042g potassium hydroxide are added in the slurry III, mixed and beaten, and the pH value of the slurry is adjusted to 5 with ammonia water to obtain the slurry IV (solid content 15%). The material is spray-dried and formed, the inlet temperature of the sprayer is 380°C, the outlet temperature is 230°C, and then roasted at a roasting temperature of 750°C and a roasting time of 6 hours to obtain an iron-based Fische...

Embodiment 2

[0036] Get 606.03g iron nitrate nonahydrate and dissolve in water to make solution I; 892.0g zinc nitrate hexahydrate and 3.13g gallium nitrate nonahydrate are dissolved in water to make solution, then this solution is mixed with 6% by weight of ammonia solution of 1860g Flow precipitation, filter the precipitation, and wash repeatedly with deionized water to obtain fresh and clean mixed oxide II of zinc oxide and gallium oxide, mix solution I and mixed oxide II to obtain slurry III; % ZrO 2 Sol and 38.4g magnesium nitrate hexahydrate and 4.20g potassium hydroxide join in the slurry III, mix beating, and the pH value of adjusting slurry with dilute nitric acid is 1 simultaneously, obtains slurry IV (solid content 45%), the The slurry is spray-dried and shaped, the inlet temperature of the sprayer is 200°C, the outlet temperature is 100°C, and then roasted at a roasting temperature of 400°C and a roasting time of 0.15h to obtain an iron-based Fischer-Tropsch synthesis catalyst ...

Embodiment 3

[0039] Get 606.03g iron nitrate nonahydrate and dissolve in water to make solution I; 780.5g zinc nitrate hexahydrate and 4.69g indium nitrate pentahydrate are dissolved in water to make solution, then this solution is mixed with 1620g of 6% by weight ammonia solution Precipitate in parallel flow, filter the precipitate, and wash repeatedly with deionized water to obtain fresh and clean mixed oxide II of zinc oxide and indium oxide, mix solution I and mixed oxide II to obtain slurry III; 40% ZrO 2 The sol and 28.62g strontium nitrate and 1.05g sodium hydroxide are added in the slurry III, mixed and beaten, and the pH value of the slurry is adjusted to 2.3 with dilute nitric acid simultaneously to obtain the slurry IV (solid content 35%), and the slurry Spray drying molding, the inlet temperature of the sprayer is 300°C, the outlet temperature is 180°C, and then roasted, the roasting temperature is 450°C, and the roasting time is 0.5h, to obtain the iron-based Fischer-Tropsch s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com