Catalyst for producing low-carbon olefins from syngas and preparation method thereof

A low-carbon olefin and catalyst technology, applied in the field of catalysts and their preparation, can solve the problems of easy flying temperature, low weight selectivity of low-carbon olefins, difficult reaction heat removal and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

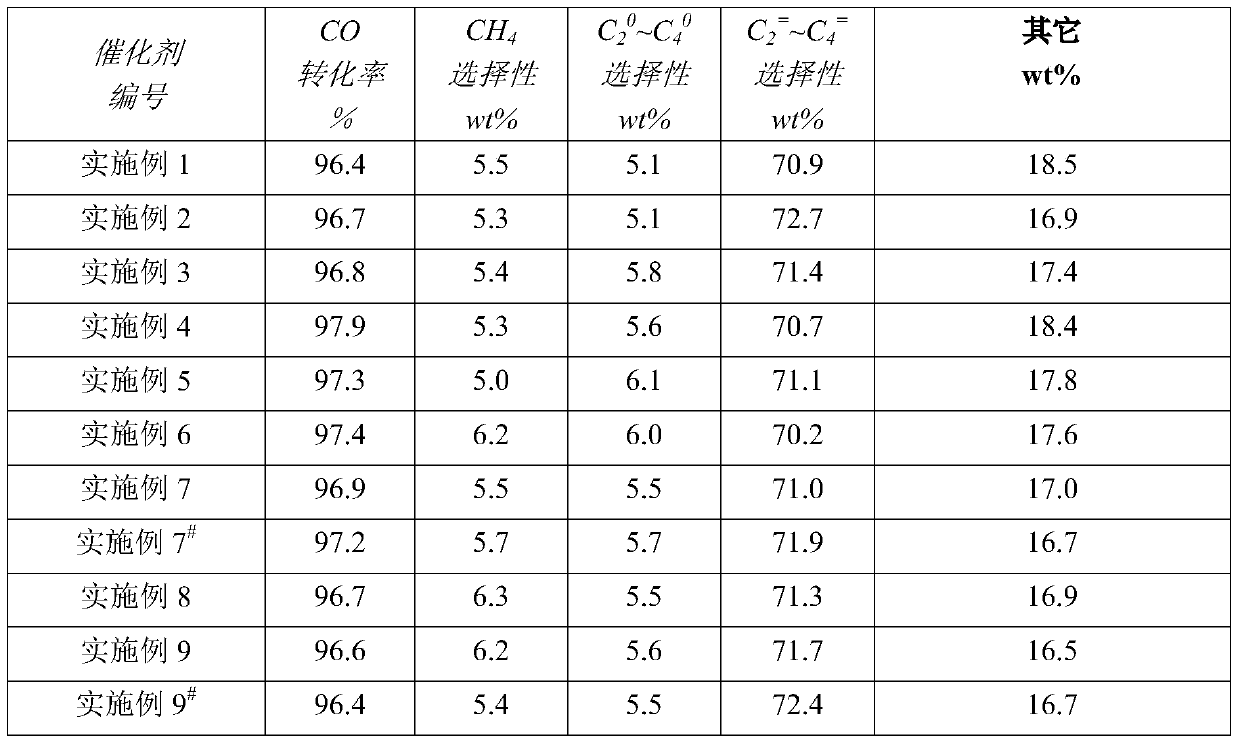

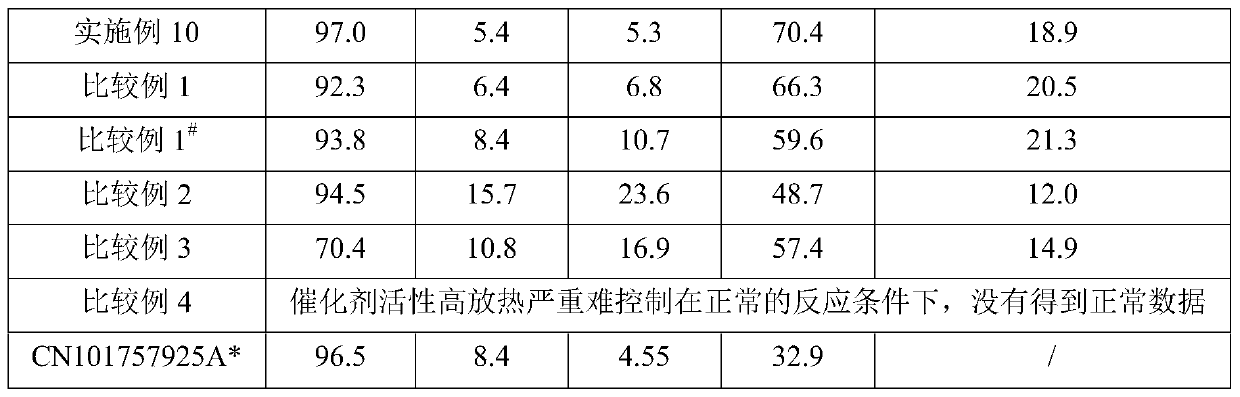

Examples

Embodiment 1

[0025] 1) Dissolve 606.03g of ferric nitrate nonahydrate and 0.314g of rhodium trichloride in water to form a solution, then centrifuge the solution and 400g of 25% by weight of concentrated ammonia water and wash it three times with deionized water to obtain Mixed precipitation Ⅰ of fresh ferric hydroxide and rhodium oxide;

[0026] 2) 134.5g of 50% by weight of manganese nitrate and 3.13g of gallium nitrate nonahydrate were dissolved in water to make solution II;

[0027] 3) mixing and beating the solution II and the mixed sediment I to obtain a colloidal slurry III;

[0028] 4) Dissolve 0.042g of potassium hydroxide in water and add it to slurry III, mix and beat, adjust the pH value of the slurry to 5 with ammonia water, and obtain a uniform slurry that is uniformly dispersed in a sol state and will not be layered after a long period of storage Material IV (45% solid content);

[0029] 5) The slurry IV is spray-dried and molded. The inlet temperature of the sprayer is 38...

Embodiment 2

[0033] 1) Get 606.03g of ferric nitrate nonahydrate and 44.79g of iridium trichloride to be dissolved in water to form a solution, then the solution is centrifuged with 400g of 25% by weight concentrated ammonia water and washed three times with deionized water to obtain Mixed precipitation of fresh ferric hydroxide and iridium oxide I;

[0034]2) 1345g of 50% by weight manganese nitrate and 117.3g of indium nitrate pentahydrate were dissolved in water to make solution II;

[0035] 3) mixing and beating the solution II and the mixed sediment I to obtain a colloidal slurry III;

[0036] 4) Dissolve 4.20g of potassium hydroxide in water and add it to the slurry III, mix and beat, adjust the pH value of the slurry to 1 with dilute nitric acid, and obtain a uniform slurry that is uniformly dispersed in the form of a sol and will not be stratified after a long period of storage Material IV (15% solid content);

[0037] 5) Slurry IV is spray-dried and molded. The inlet temperature...

Embodiment 3

[0041] 1) Dissolve 367.43g of iron citrate and 1.57g of rhodium trichloride in water to form a solution, and then centrifuge the solution and 400g of 25% by weight of strong ammonia in parallel flow, and wash with deionized water three times to obtain fresh hydrogen Mixed precipitation of iron oxide and rhodium oxide Ⅰ;

[0042] 2) 269.0g of 50% by weight of manganese nitrate and 125.2g of gallium nitrate nonahydrate were dissolved in water to make solution II;

[0043] 3) mixing and beating the solution II and the mixed sediment I to obtain a colloidal slurry III;

[0044] 4) Dissolve 1.05g of sodium hydroxide in water and add it to slurry III, mix and beat, and at the same time adjust the pH of the slurry to 3 with dilute ammonia water to obtain a sol-like dispersion that is uniform and will not be layered after long-term storage. Slurry IV (solid content 35%);

[0045] 5) Slurry slurry IV is spray-dried and formed, the inlet temperature of the sprayer is 230°C, the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com