Power-variable frequency operation synchronization switching method based on high voltage frequency converter motor control system

A high-voltage frequency converter and variable frequency operation technology, which is applied in the control system, vector control system, motor generator control, etc., can solve the problem that the load cannot be applied to heavy-duty starting or constant torque starting, the deviation between the output current of the frequency converter and the motor current, Thyristor soft starter has small starting torque and other problems, so as to solve the problem of starting torque and low-speed load capacity, suppress circulating current, and reduce equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

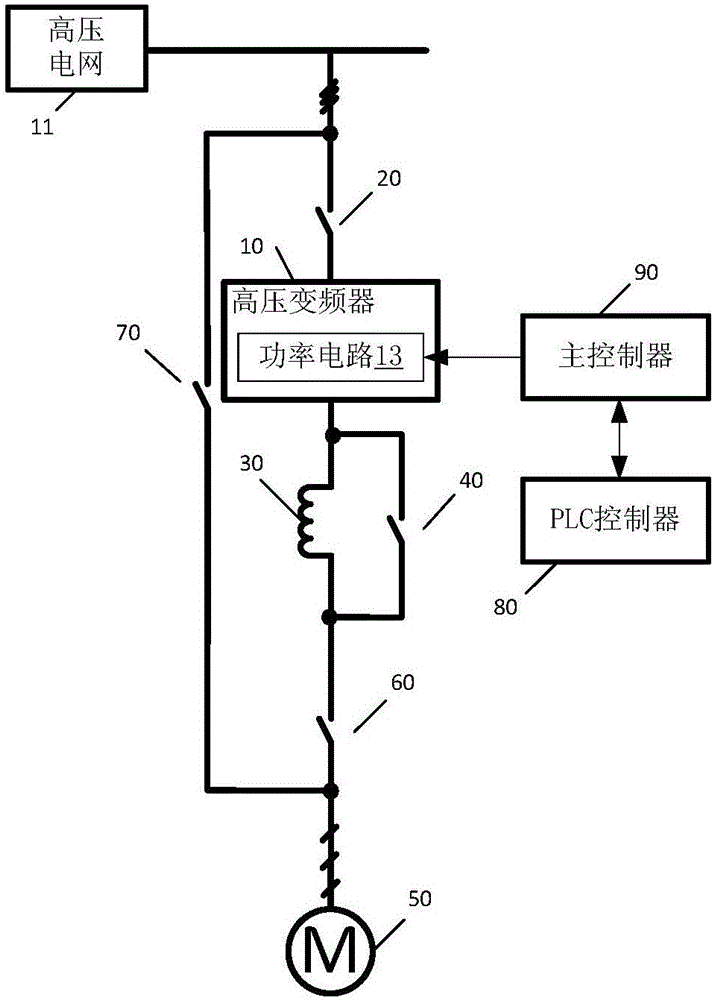

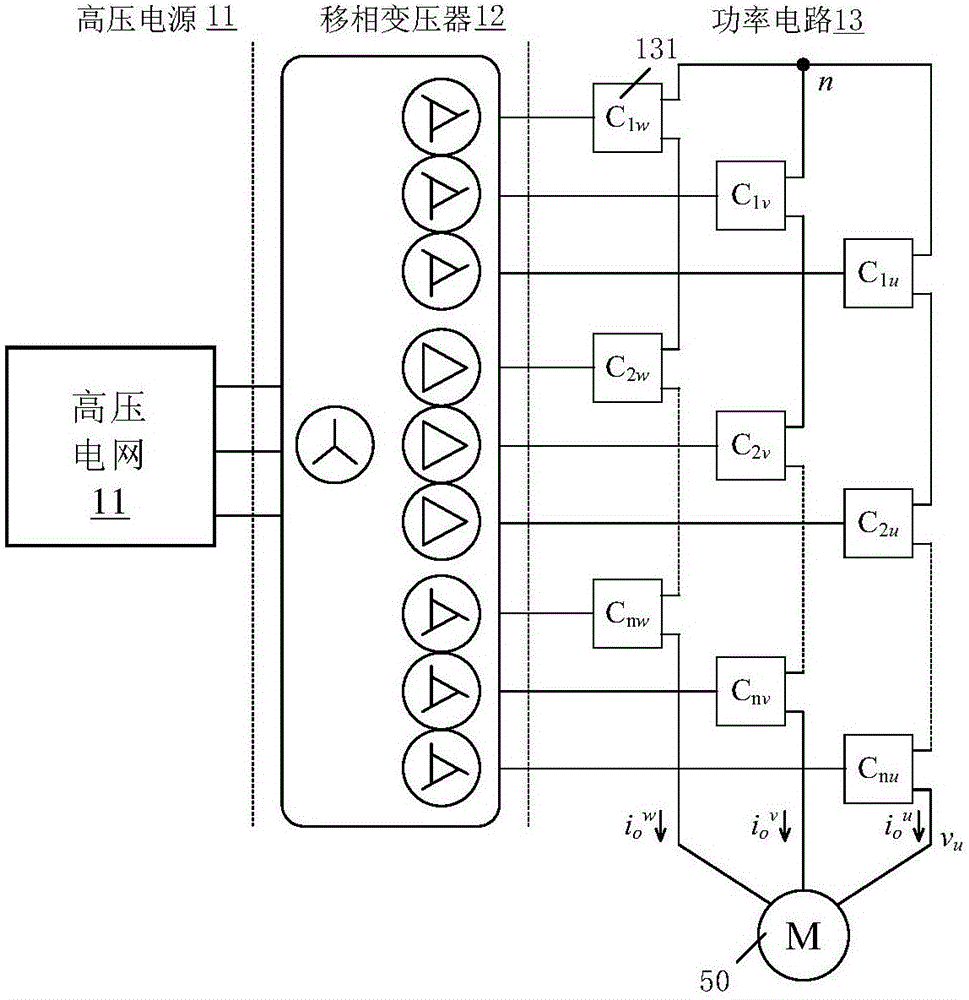

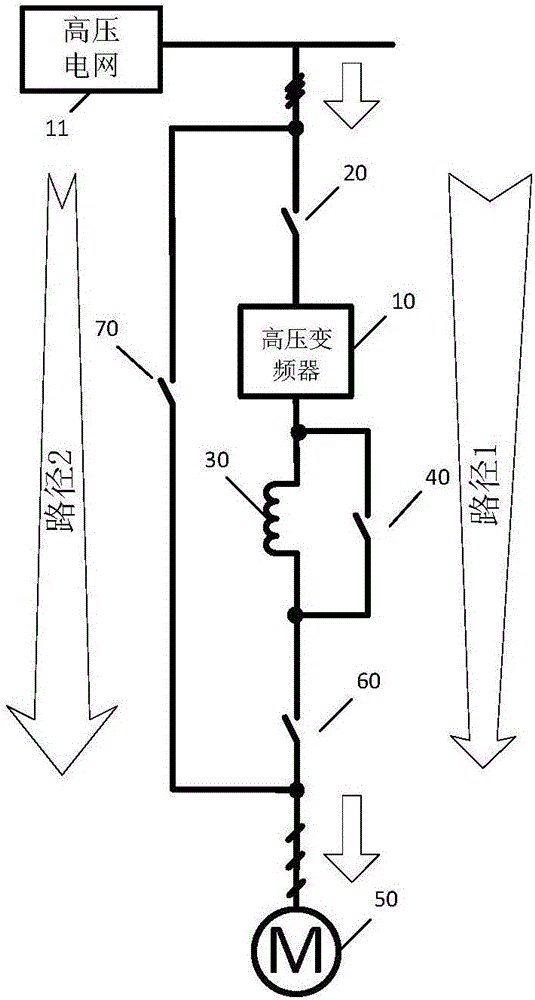

[0030] The present invention is suitable for high-voltage frequency converter motor control systems, such as figure 1The high-voltage frequency converter motor control system includes a high-voltage frequency converter 10, the high-voltage input terminal of the high-voltage frequency converter 10 is connected to the three-phase high-voltage bus bar of the high-voltage power grid 11 through the input contactor 20, and the high-voltage output terminal of the high-voltage frequency converter 10 is connected through the output contactor 60 1. The circulating current suppressing reactor 30 is connected to the input end of the high voltage motor 50, the grid access contactor 70 is connected between the high voltage power grid 11 and the high voltage motor 50, and each power unit 131 in the power circuit 13 in the high voltage frequency converter 10 passes through an optical fiber The communication is controlled by the main controller 90 to realize the frequency conversion control of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com