Motor air-cooled casing based on integrated extrusion molding and phase-change heat pipe technology

An extrusion molding, air-cooled machine technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc. The temperature control performance of the machine can not be effectively used, so as to achieve excellent temperature control performance, eliminate the problem of local temperature overheating, and realize the effect of heat distribution and reorganization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

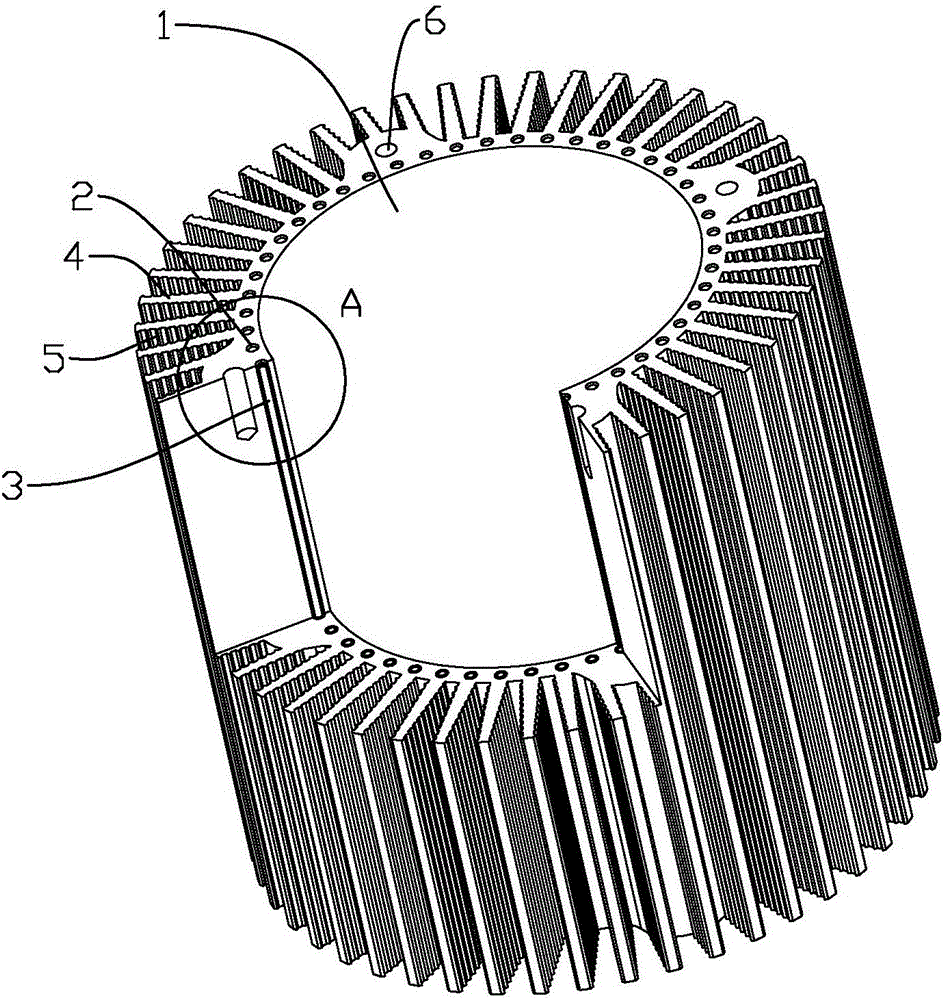

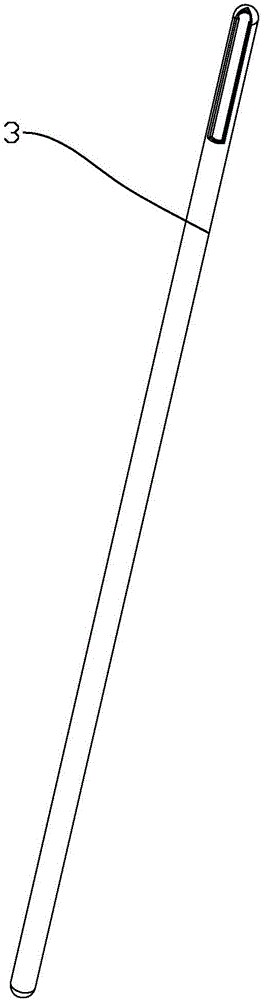

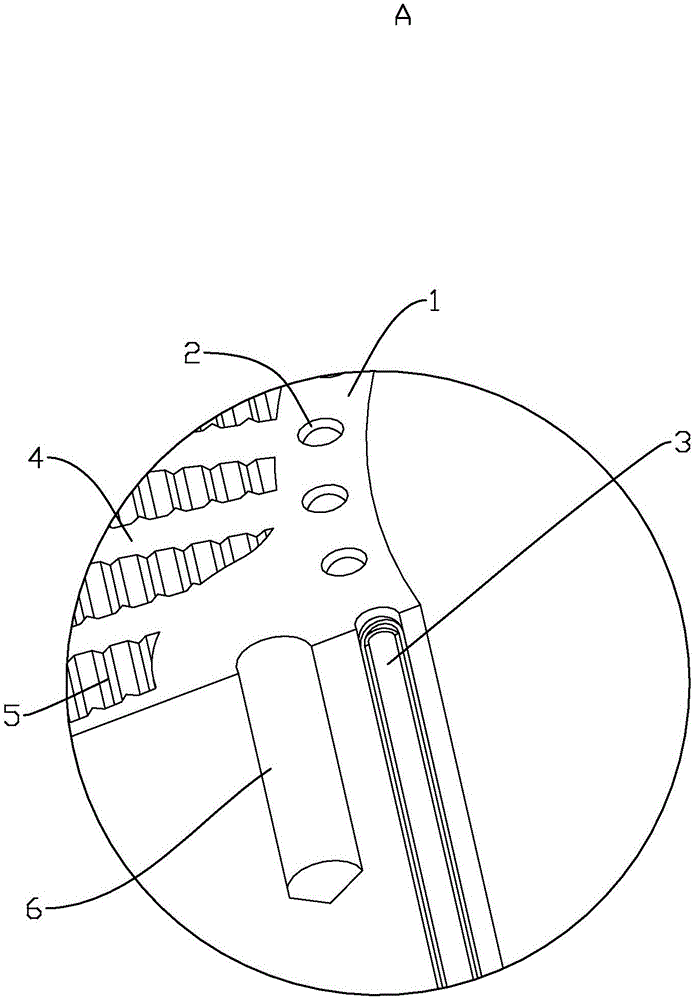

[0021] refer to Figure 1 ~ Figure 3 , the present invention is a motor air-cooled casing based on integrated extrusion molding and phase change heat pipe technology, including a tubular casing 1, at least four mounting holes 2 are arranged in the side wall of the casing 1, and there are installed in the mounting holes 2 The phase change heat pipe 3 is provided with cooling fins 4 on the outer wall of the housing 1 . The present invention adopts the phase change heat pipe 3 as the heat conduction and heat equalization component. The phase change heat pipe 3 has extremely efficient heat transfer capacity, and its thermal conductivity is tens of thousands of times that of known metals, and can realize rapid reorganization of heat distribution inside the drive motor. Installing it in the mounting hole 2 of the casing 1 can quickly spread and diffuse a large amount of heat originally concentrated in the contact part of the stator core and the casing 1 to the entire casing 1, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com