Preparation method of high-density lithium iron phosphate material

A lithium iron phosphate, high-density technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficulty in densification, difficulty in improving compaction density, and difficulty in ensuring the regularity of secondary particles, and achieve high production efficiency. , The effect of convenient operation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

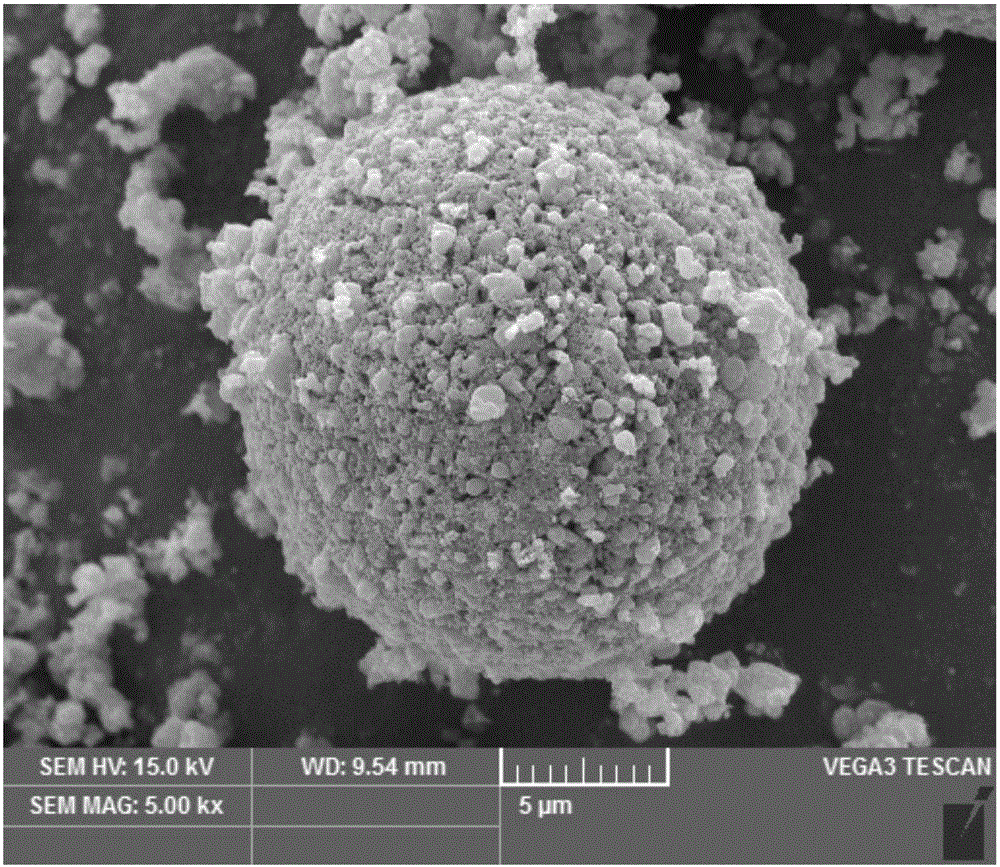

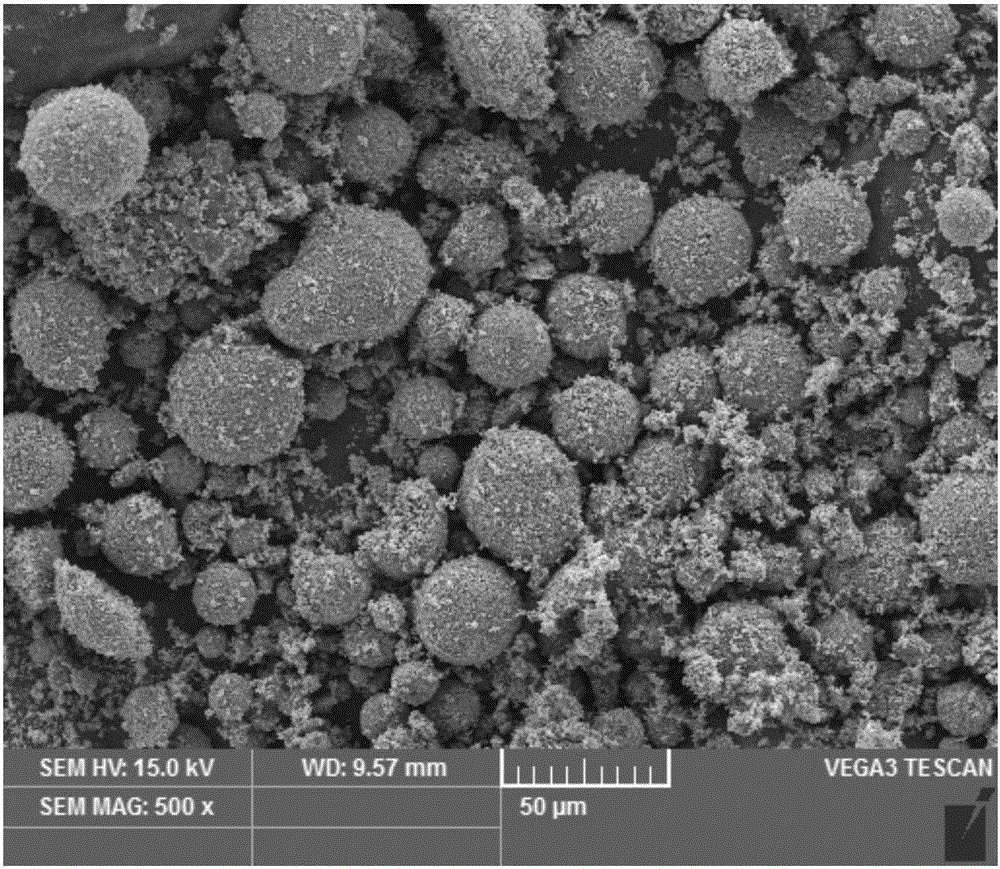

[0029] A method for preparing a high-density lithium iron phosphate material, comprising the following processes:

[0030] 1) Manufacture spherical iron phosphate

[0031] First, dry-mill the anhydrous ferric phosphate until its average particle size reaches below 0.5um, take it out and put it into a fusion spheroidizer to continue shaping;

[0032] 2) Preparation of spherical precursor

[0033] After uniformly mixing the iron phosphate with the lithium source and the carbon source, it is further ground in a liquid phase system, and then made into a dry spherical precursor by a spray method;

[0034] 3) Precursor densification

[0035] Place the spherical precursor in a high-pressure chamber, pressurize it for 0.2-5 hours with an air pressure of 10-100MPa, take it out and sinter it in an electric furnace;

[0036] 4) Prepare high-density lithium iron phosphate

[0037] The sintered material is graded by a classifier, and the lithium iron phosphate materials of different pa...

Embodiment 2

[0041] A method for preparing a high-density lithium iron phosphate material, comprising the following processes:

[0042] 1) Manufacture spherical iron phosphate

[0043] First, dry-mill the anhydrous ferric phosphate until its average particle size reaches below 0.5um, take it out and put it into a fusion spheroidizer to continue shaping;

[0044] 2) Preparation of spherical precursor

[0045] After uniformly mixing the iron phosphate with the lithium source and the carbon source, it is further ground in a liquid phase system, and then made into a dry spherical precursor by a spray method;

[0046] 3) Precursor densification

[0047] Place the spherical precursor in a high-pressure chamber, pressurize it for 0.2-5 hours with an air pressure of 10-100MPa, take it out and sinter it in an electric furnace;

[0048] 4) Prepare high-density lithium iron phosphate

[0049] The sintered material is graded by a classifier, and the lithium iron phosphate materials of different pa...

Embodiment 3

[0053] A method for preparing a high-density lithium iron phosphate material, comprising the following processes:

[0054] 1) Manufacture spherical iron phosphate

[0055] First, dry-mill the anhydrous ferric phosphate until its average particle size reaches below 0.5um, take it out and put it into a fusion spheroidizer to continue shaping;

[0056] 2) Preparation of spherical precursor

[0057]After uniformly mixing the iron phosphate with the lithium source and the carbon source, it is further ground in a liquid phase system, and then made into a dry spherical precursor by a spray method;

[0058] 3) Precursor densification

[0059] Place the spherical precursor in a high-pressure chamber, pressurize it for 0.2-5 hours with an air pressure of 10-100MPa, take it out and sinter it in an electric furnace;

[0060] 4) Prepare high-density lithium iron phosphate

[0061] The sintered material is graded by a classifier, and the lithium iron phosphate materials of different par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com