Method for preparing porous silicon/TiO2 composite negative electrode material by taking diatomite as raw material

A technology of titanium dioxide and negative electrode materials, which is applied in the field of preparing porous silicon/titanium dioxide composite negative electrode materials, can solve the problems of destroying the nano-silicon crystal structure, degradation of battery cycle performance, and easy aggregation of nano-silicon particles, so as to achieve abundant raw material resources, low price, Scientific and reasonable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of method that prepares porous silicon / titanium dioxide composite negative electrode material with diatomite as raw material, it comprises the following steps:

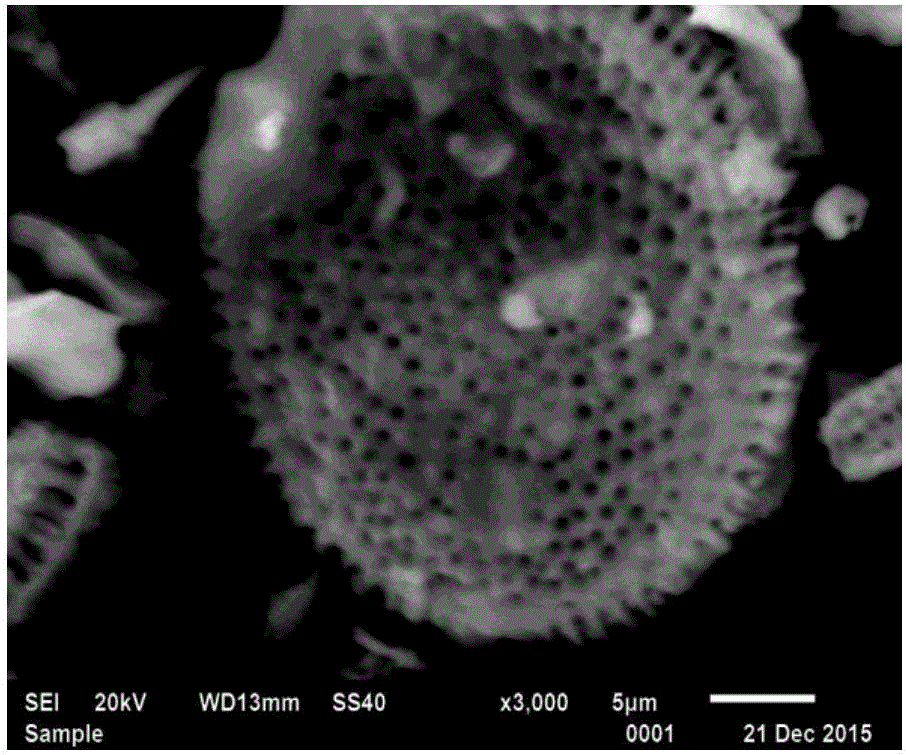

[0030] (1) Purification treatment of diatomite: put diatomite raw soil in a muffle furnace, heat up to 600°C under air atmosphere, calcinate for 5h to remove organic matter, then disperse in 0.01mol / L NaOH solution, stir for 3h , to filter, put the filtered filter cake in an oven, dry at 60°C for 10h, take it out, pour it into an acid solution with a concentration of 4mol / L, and stir it at 80°C for 3h to remove iron oxide, di aluminum, magnesium oxide, then washed with water until neutral, and dried at 60°C for 10 hours to obtain purified diatomite; figure 1 In order to obtain the purified diatomite scanning electron micrograph;

[0031] (2) Preparation of porous silicon / titanium dioxide composite anode material: Add 0.05 g of purified diatomaceous earth to 20 mL of absolute ethanol, then ...

Embodiment 2

[0033] Embodiment 2: a kind of method that prepares porous silicon / titanium dioxide composite negative electrode material with diatomite as raw material, it comprises the following steps:

[0034] (1) Purification treatment of diatomite: put diatomite raw soil in a muffle furnace, heat up to 650°C in an air atmosphere, calcinate for 4 hours to remove organic matter, then disperse in 0.01mol / L NaOH solution, and stir for 3 hours , to filter, put the filtered filter cake in an oven, and dry at 60° C. for 10 h. After taking it out, pour it into an acid solution with a concentration of 5mol / L, stir at 85°C for 3 hours to remove iron oxide, aluminum oxide, and magnesium oxide, then wash with water until neutral, and dry at 60°C for 10 hours to obtain purified After the diatomaceous earth;

[0035] (2) Preparation of porous silicon / titanium dioxide composite anode material: Add 0.10 g of purified diatomaceous earth to 25 mL of absolute ethanol, then add 0.15 mL of deionized water a...

Embodiment 3

[0037]Embodiment 3: a kind of method that prepares porous silicon / titanium dioxide composite negative electrode material with diatomite as raw material, it comprises the following steps:

[0038] (1) Purification treatment of diatomite: put diatomite raw soil in a muffle furnace, heat up to 700°C under air atmosphere, calcinate for 4h to remove organic matter, then disperse in 0.01mol / L NaOH solution, stir for 6h , to filter, put the filtered filter cake in an oven, and dry at 60° C. for 10 h. After taking it out, pour it into an acid solution with a concentration of 6mol / L, stir at 90°C for 8 hours to remove iron oxide, aluminum oxide, and magnesium oxide, then wash with water until neutral, and dry at 60°C for 10 hours to obtain purified After the diatomaceous earth;

[0039] (2) Preparation of porous silicon / titanium dioxide composite anode material: Add 0.15 g of purified diatomaceous earth to 30 mL of absolute ethanol, then add 0.2 mL of deionized water and 0.05 g of hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com