Preparation method for fluorine-doped nickel-cobalt-manganese system ternary positive electrode material and prepared material

A cathode material, nickel-cobalt-manganese technology, which is applied in the field of preparing fluorine-doped nickel-cobalt-manganese-based ternary cathode materials by molten salt method, can solve the problems of high reaction time and reaction temperature, reduced battery performance, uneven heating, and the like. Achieve the effect of low production cost, good consistency and large diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The specific embodiment of the present invention provides a method for preparing a fluorine-doped nickel-cobalt-manganese ternary cathode material. The method includes the following steps:

[0071] (1) Mixing the transition metal source aqueous solution, lye and ammonia, stirring and heating for reaction, the precipitate obtained from the reaction is aged, filtered, washed and dried to obtain a nickel, cobalt and manganese composite precursor;

[0072] (2) The nickel-cobalt-manganese composite precursor obtained in step (1) is heat-treated at 500°C to 550°C, and then mixed with a lithium source and a fluorine source, and then a flux is added, mixed and made into a green body;

[0073] (3) Place the green body described in step (2) in a reaction furnace at a constant temperature of 700°C to 1000°C for constant temperature calcination, and then cool, wash and dry to obtain a fluorine-doped nickel-cobalt-manganese ternary cathode material.

Embodiment 1

[0076] This embodiment provides a method for preparing a fluorine-doped nickel-cobalt-manganese ternary positive electrode material. The method includes the following steps:

[0077] (1) Take 100 mL of a mixed aqueous solution of nickel, cobalt and manganese sulfate with an ion concentration of 2.5 mol / L (the molar ratio of nickel ions, manganese ions and cobalt ions is 5:2:3), and add them to a stirring device In the reactor, argon gas was added while slowly adding 5mol / L sodium hydroxide solution and 5mol / L ammonia solution, reacting at 55℃ for 20h under an inert atmosphere, adjusting the pH to stabilize at 12, and filtering and After ultrasonic washing, Ni is obtained 0.5 Co 0.2 Mn 0.3 (OH) 2 Precursor slurry;

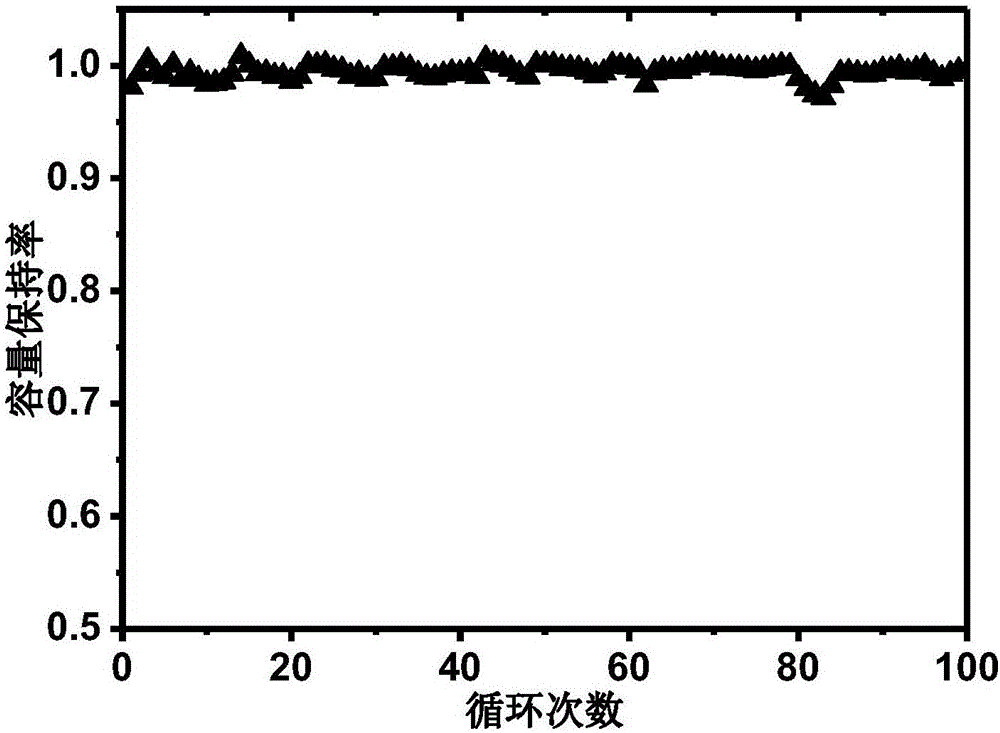

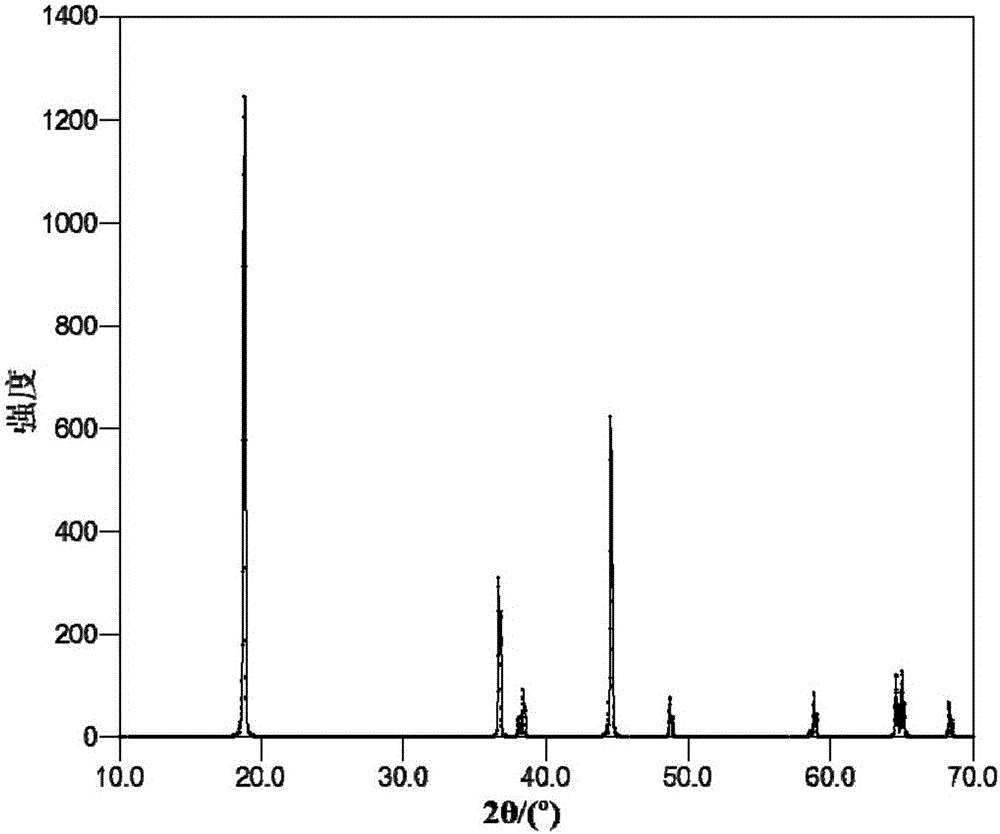

[0078] (2) The Ni obtained in step (1) 0.5 Co 0.2 Mn 0.3 (OH) 2 The precursor slurry is heat treated at 500℃ for 6h, and then press LiNi 0.5 Co 0.2 Mn 0.3 O 1.85 F 0.15 Weigh the lithium hydroxide and lithium fluoride (the molar ratio is 25:3) and mix them, then add 10 t...

Embodiment 2

[0083] This embodiment provides a method for preparing a fluorine-doped nickel-cobalt-manganese ternary positive electrode material. The method includes the following steps:

[0084] (1) Take 200 mL of a mixed aqueous solution of nickel, cobalt, and manganese sulfate with an ion concentration of 2mol / L (the molar ratio of nickel, manganese, and cobalt ions is 1:1:1) and add it to the reaction with a stirring device In the vessel, argon gas, while slowly adding 10mol / L sodium hydroxide solution and 5mol / L ammonia aqueous solution, react at 50℃ for 24h under inert atmosphere, adjust the pH to stabilize at 11.5, filter and ultrasonically wash , Get Ni 1 / 3 Co 1 / 3 Mn 1 / 3 (OH) 2 Precursor slurry;

[0085] (2) The Ni obtained in step (1) 1 / 3 Co 1 / 3 Mn 1 / 3 (OH) 2 The precursor slurry is heat treated at 550℃ for 7h, then press LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 1.9 F 0.1 Weigh the lithium hydroxide and lithium fluoride (the molar ratio is 9:1) and mix them, and then add the nickel-cobalt-manganese co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com