Organic electrode resistive random access memory and preparation method thereof

A resistive variable memory and organic electrode technology, applied in the direction of electrical components, etc., can solve the problems of poor durability and data memory characteristics, poor storage performance, unstable resistance change, etc., and achieve simple and easy preparation methods and high storage performance. The effect of stability and concentrated resistance distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

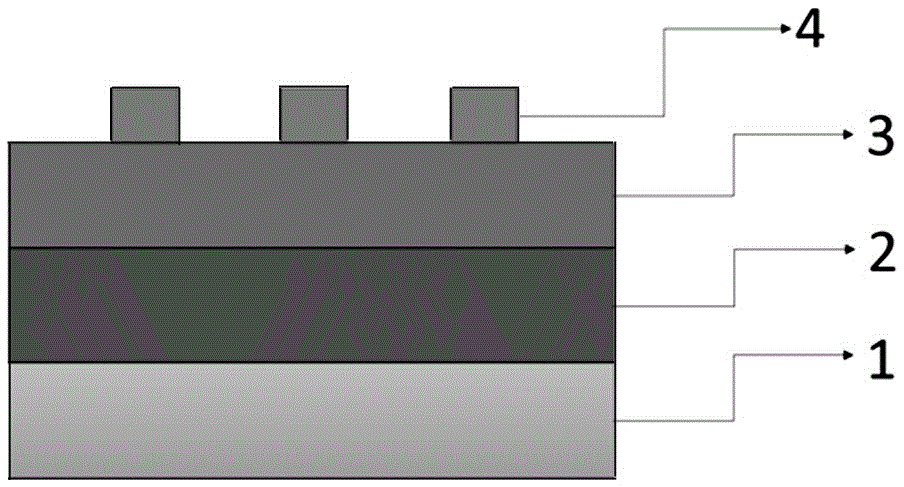

[0033] The structure of the resistive memory prepared by the present invention is as follows: figure 1 As shown, including the bottom substrate 1, the PCBM organic electrode dielectric layer 2 bonded on the substrate 1, and the Zr grown on the PCBM organic electrode dielectric layer 2 0.5 f 0.5 o 2 Resistive switching layer 3, Zr 0.5 f 0.5 o 2 An Ag electrode layer 4 grown on the resistive switching layer 3 .

[0034] Wherein the substrate 1 can be an FTO substrate or a glass substrate, and the thickness of the PCBM organic electrode dielectric layer 2 is 10~300nm; Zr 0.5 f 0.5 o 2 The thickness of the resistive switching layer 3 is 3-50 nm.

[0035] Wherein the thickness of Ag electrode layer 4 can be in the range of 50nm~200nm; Ag electrode layer 4 includes several evenly distributed in Zr 0.5 f 0.5 o 2 A circular electrode with a diameter of 80-300 μm on the resistive switching layer 3 .

Embodiment 2

[0037] The preparation method of the resistive memory provided by the present invention comprises the following steps:

[0038] (1) Wipe the surface of the FTO substrate with absorbent cotton dipped in acetone and absolute ethanol in sequence to wipe off small particles such as dust attached to the surface, and initially remove the oil on the surface, and then place the FTO substrate on the acetone Use ultrasonic cleaning for 10 minutes, then put it into alcohol and use ultrasonic cleaning for 10 minutes, then take it out with a clip, put it in deionized water and use ultrasonic cleaning for 5 minutes, then take it out, and use N 2 blow dry;

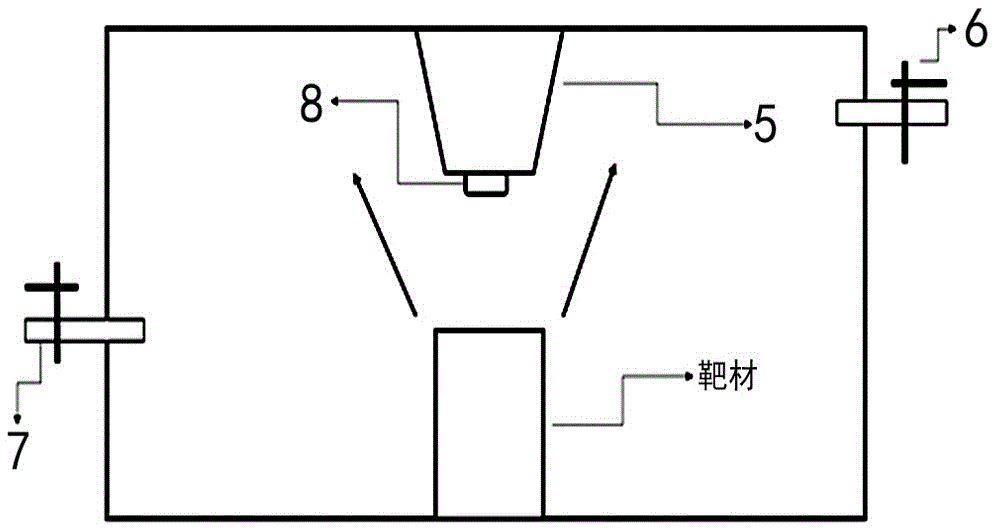

[0039] (2) Dissolve 10mg of PCBM in 1mL of chloroform, mix well, and then filter the obtained solution with a 0.22 micron filter to obtain PCBM solution; start to load the sample, open the cover of the plastic machine, turn on the vacuum pump, and wash the 1. The dried FTO substrate is vacuumed and adsorbed in the middle of the tray of ...

Embodiment 3

[0044] Embodiment 3 performance test

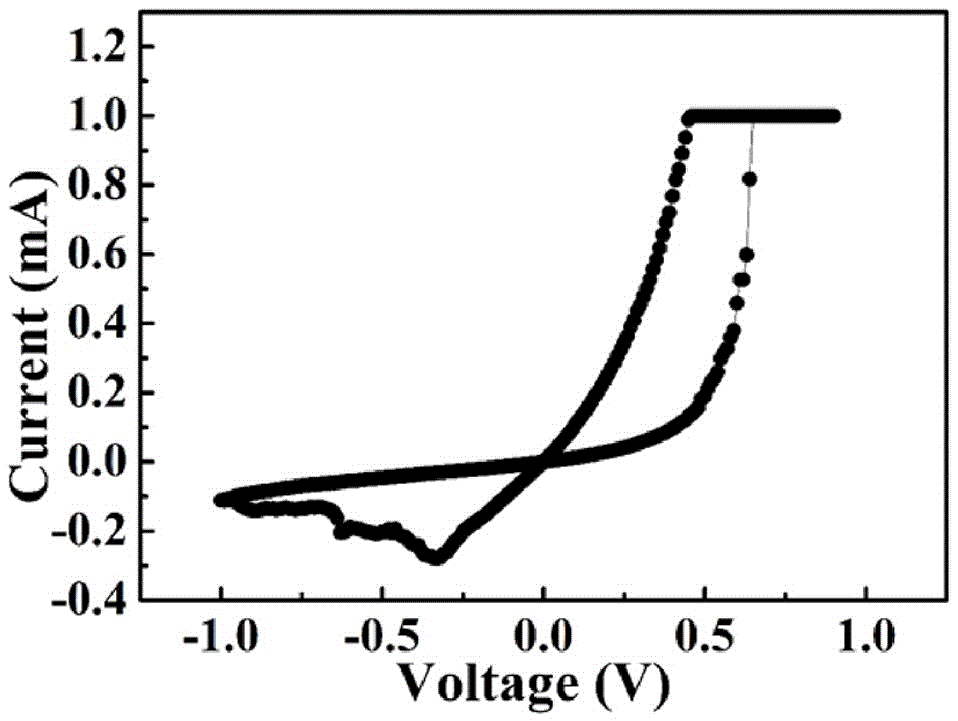

[0045] Measure its current-voltage characteristic curve by being added to the scan voltage of the resistive memory that embodiment 2 prepares, and the results are shown in image 3 . Depend on image 3 It can be seen that when the forward scanning voltage gradually increases from 0V to 1.0V, the device is in a high resistance state (lower current) at the beginning, and its resistance state gradually changes from high resistance to low when it is around 0.5V. As the voltage increases, the low resistance state reaches a stable value; after reaching the maximum scanning voltage, the scanning voltage begins to decrease gradually, when the scanning voltage continues to decrease to 0V, and then begins to scan negatively to - At about 0.35V, the off voltage is reached, and the low-resistance state is slowly and gradually transformed into a high-resistance state, and the device remains in a high-resistance state until the voltage sweeps back to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com