Gas engine compression absorption compound heat pump heat supply method with series and parallel switching

A technology of gas engine and gas engine, which is applied to the operation mode of machines, machines and pumps that use waste heat, etc. It can solve the problems of increased power consumption of compressors, attenuation of heating capacity, and limitations on the application range of gas engine-driven composite heat pump systems, etc. problems, to achieve the effects of reducing discharge temperature, reducing power consumption, and efficient and clean utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

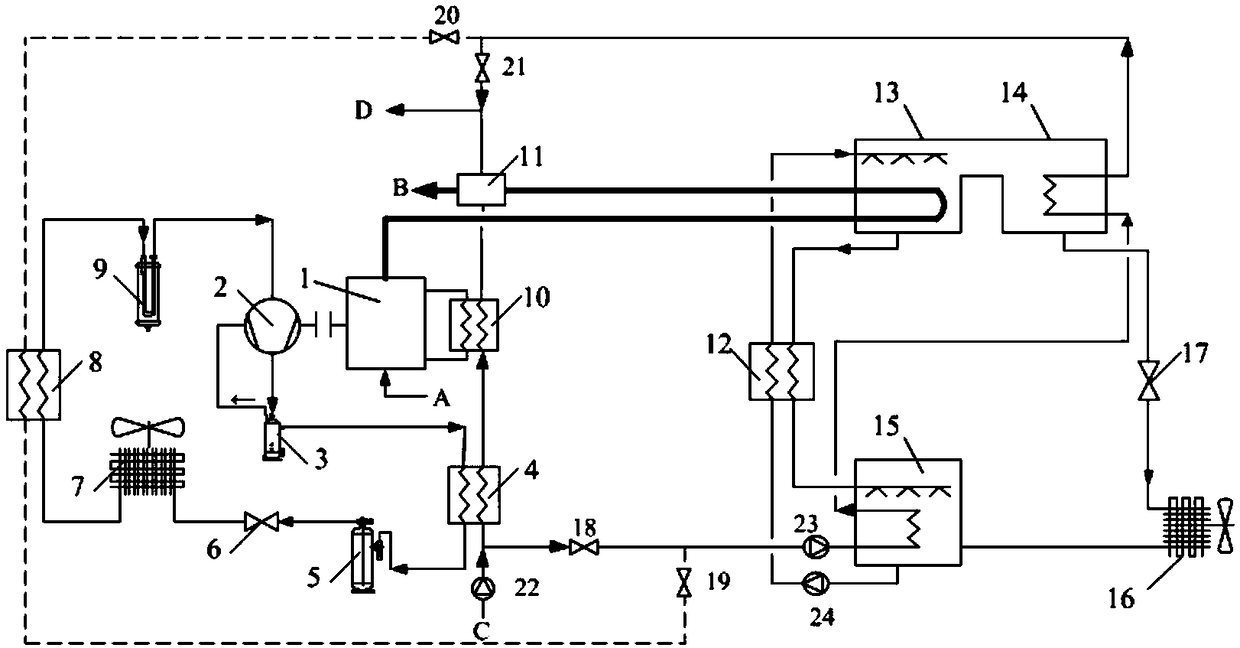

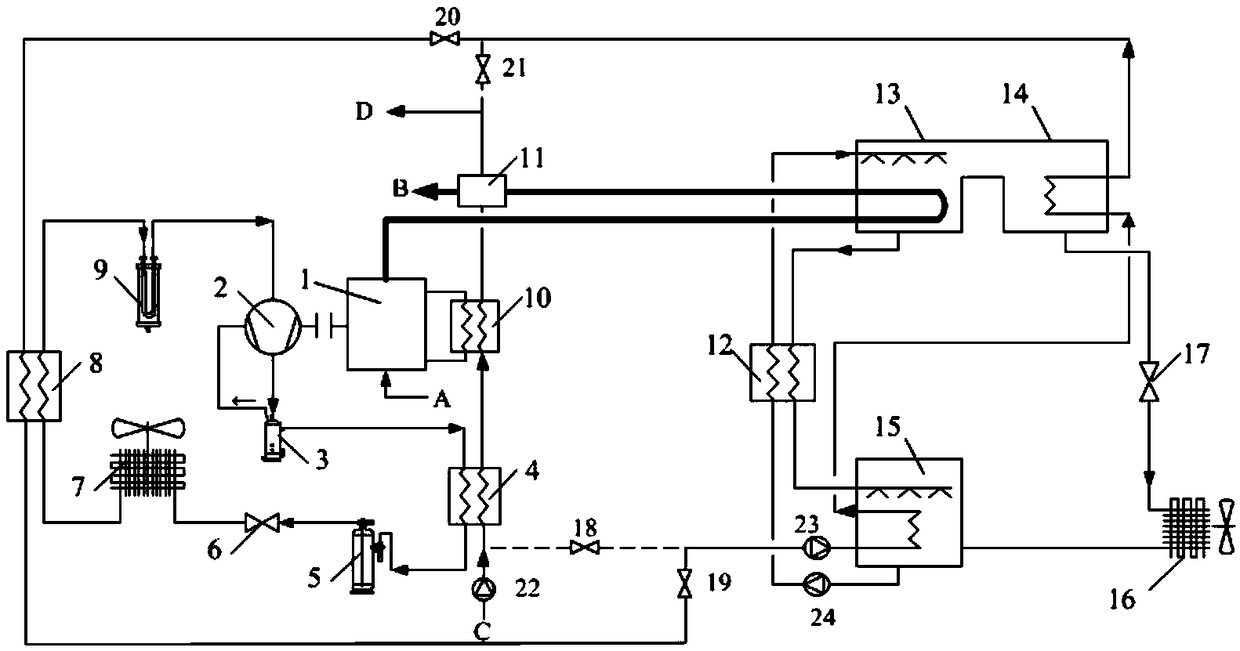

[0030] In warm areas, take floor heating radiation heating as an example, when the return water temperature of the heat user is 35°C, and the best ambient air temperature for mode switching is 0°C, the specific control method is as follows:

[0031] When the outdoor air temperature is higher than or equal to 0 ℃, the heating method of gas engine compression absorption compound heat pump switching in series and parallel is parallel mode. When the ambient temperature is 10°C, the specific process is as follows: natural gas and air enter the gas engine 1 through the natural gas and air inlet A of the gas engine to burn and provide power for the gas engine 1, and the gas engine 1 drives the compressor 2 to convert the refrigerant into the compression heat pump system Compressed into a gaseous state at 75°C, the gaseous refrigerant passes through the oil separator 3 to separate lubricating oil and refrigerant, the lubricating oil returns to the compressor, and the refrigerant passes...

Embodiment 2

[0035] In cold regions, take radiant floor heating as an example, when the return water temperature is 35°C and the best ambient air temperature when switching modes is -5°C, the specific control methods are as follows:

[0036]When the outdoor air temperature is higher than or equal to -5°C, the gas engine compression absorption compound heat pump heating method switched in series and parallel is the parallel mode. When the ambient temperature is -5°C, the specific process is: natural gas and air enter the gas engine 1 through the natural gas and air inlet A of the gas engine to burn and provide power for the gas engine 1, and the gas engine 1 drives the compressor 2 to cool the compression heat pump system The refrigerant is compressed into a gaseous state at 65°C. The gaseous refrigerant passes through the oil separator 3 to separate lubricating oil and refrigerant, and the lubricating oil returns to the compressor. The refrigerant passes through the first condenser 4 to exc...

Embodiment 3

[0040] In severe cold areas, take floor heating radiation heating as an example, when the return water temperature of the heat user is 35°C, and the best ambient air temperature when the mode is switched is -10°C, the specific control steps are as follows:

[0041] When the outdoor air temperature is higher than or equal to -10°C, the gas engine compression absorption compound heat pump heating method switched in series and parallel is the parallel mode. When the ambient temperature is -10°C, the specific process is: natural gas and air enter the gas engine 1 through the natural gas and air inlet A of the gas engine to burn and provide power for the gas engine 1, and the gas engine 1 drives the compressor 2 to cool the compression heat pump system The refrigerant is compressed into a gaseous state at 55°C. The gaseous refrigerant passes through the oil separator 3 to separate the lubricating oil and refrigerant, and the lubricating oil returns to the compressor. The refrigerant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com