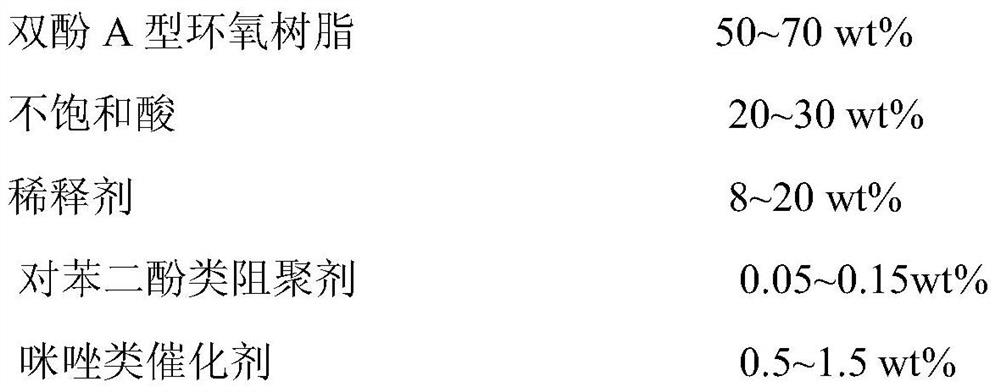

A modified epoxy resin small tow universal carbon fiber sizing agent, preparation method and application thereof

A technology of epoxy resin and small tow, which is applied in the fields of carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of difficulty in carbon fiber preparation and cost increase, no carbon fiber sizing agent has been found, and product stability is difficult to guarantee. Improved binding ability, relief of high viscosity, and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] 1. Preparation of sizing agent

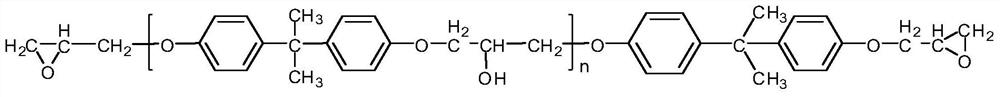

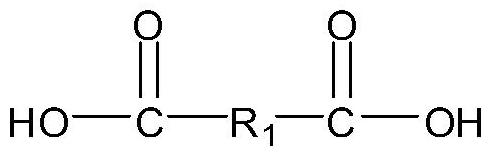

[0048] Put quantitative bisphenol A type epoxy resin (Shell Company, USA) in a four-necked flask with a mechanical stirring device, heat to 110°C, and maintain a vacuum pressure of 10-0.5mmHg for 2 hours to dehydrate until the system is completely free of bubbles. Cool down to 70°C, feed 99.999% high-purity nitrogen gas, and remove the vacuum device at the same time. In the four-necked flask, add quantitative diluent, hydroquinone polymerization inhibitor, unsaturated acid, imidazole catalyst (all adopted from Sinopharm Chemical Reagent Co., Ltd.) successively, control the material temperature at 70 ℃ for 7 hours, and then After heating up to 120° C. for 2.5 hours, the heating was stopped. When the temperature of the system drops to normal temperature, the stirring is stopped to obtain the unsaturated acid-modified epoxy resin sizing agent.

[0049] See Tables 1-2 for the types and amounts of the bisphenol-A epoxy resin, unsaturated ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com