Multiferroic composite magnetoelectric film and preparation method thereof

A multiferroic and thin-film technology, applied in liquid chemical plating, metal material coating process, coating, etc., to achieve the effect of low preparation cost, stable performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A. Preparation of precursor solution

[0040] Weigh 0.0084mol of lanthanum nitrate, 0.0036mol of strontium acetate and 0.012mol of manganese chloride, add 40mL of glacial acetic acid, heat to reflux to dissolve the solute completely, and obtain a transparent yellow solution; let it stand for 2 days, filter through a 0.22μm microporous Membrane filtration can obtain stable lanthanum strontium manganese oxide (La 0.7 Sr 0.3 MnO 3 ) precursor solution;

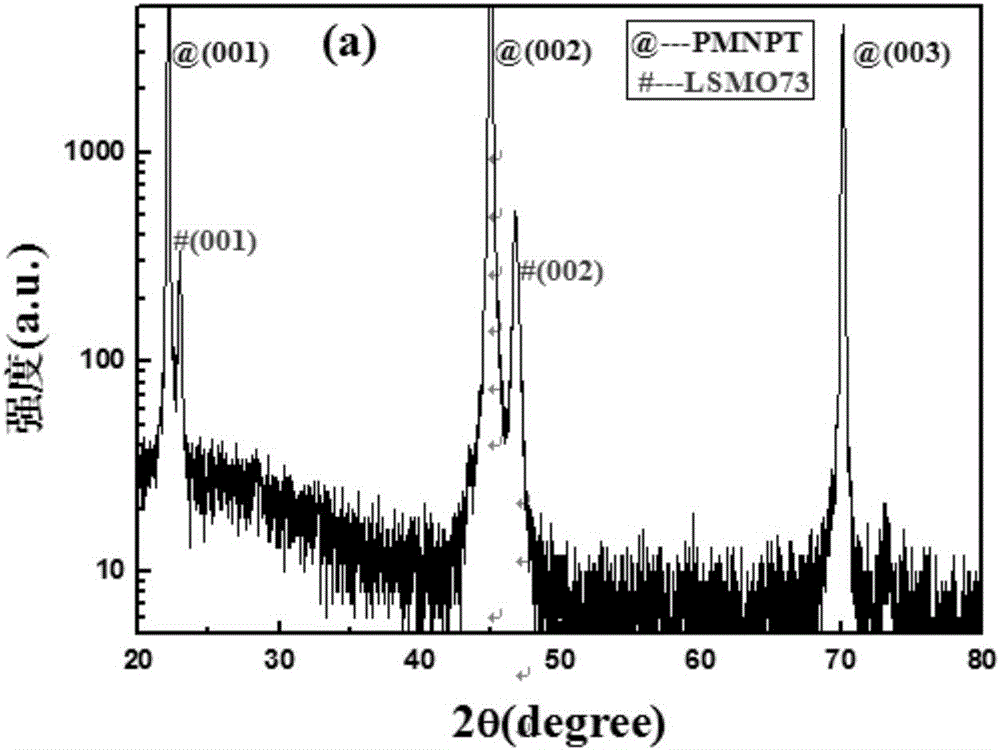

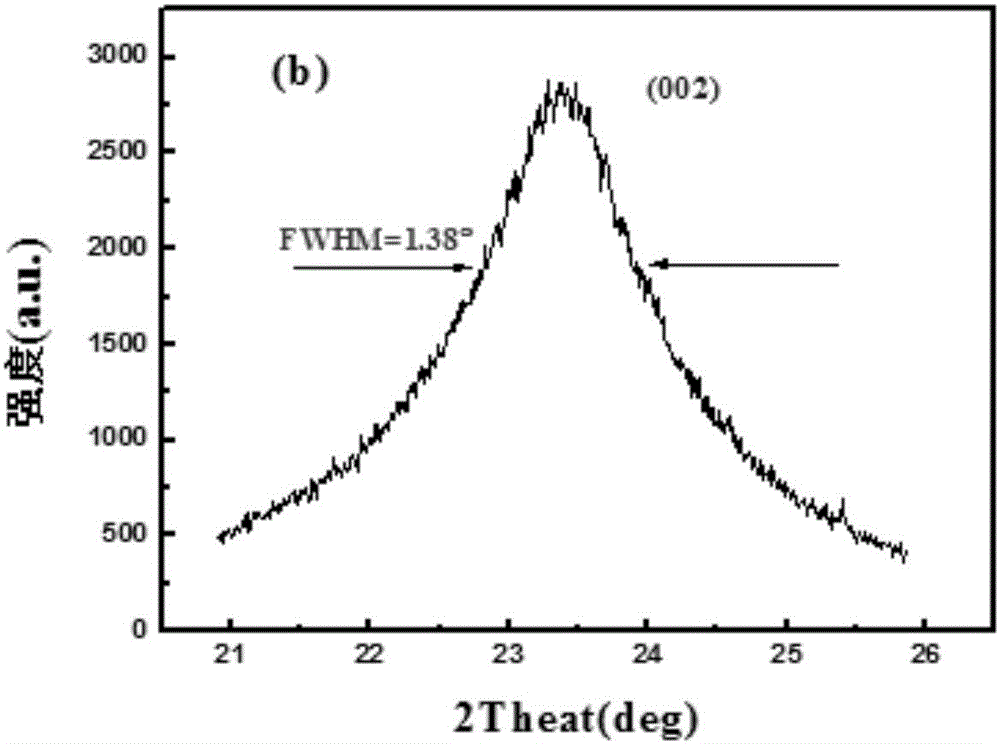

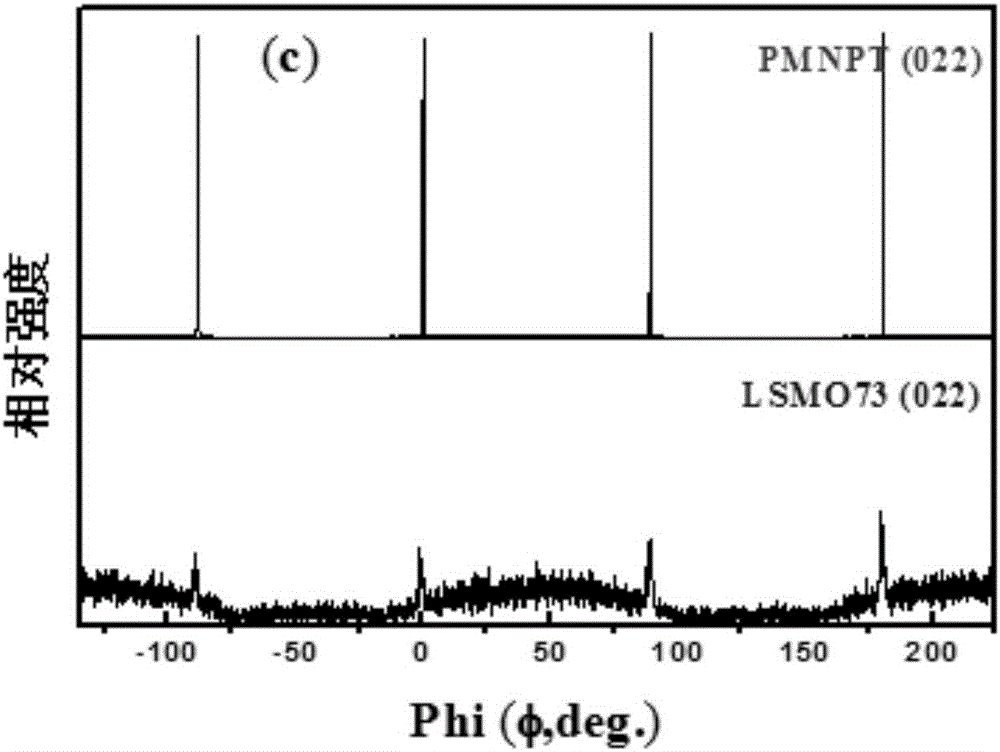

[0041] B. Preparation of composite magnetoelectric thin film

[0042] Firstly, the (001) PMN-PT substrate was baked on a hot stage at 400°C for 30 minutes to reduce the stress on its surface. Using a homogenizer, drop the prepared LRMO precursor solution onto the cleaned (001) PMN-PT single crystal substrate rotating at a high speed at a constant speed. The speed of the substrate is first 400rpm for 10s, then 3000rpm for 40s , to obtain a layer of lanthanum strontium manganese oxide gel film; place it in a rapid annea...

Embodiment 2

[0044] A. Preparation of precursor solution

[0045] Weigh 0.006mol of lanthanum nitrate, 0.006mol of strontium acetate and 0.012mol of manganese chloride, add 30mL of glacial acetic acid, heat to reflux to dissolve the solute completely, and obtain a transparent yellow solution; let it stand for 2 days, filter through a 0.22μm microporous Membrane filtration can obtain stable lanthanum strontium manganese oxide (La 0.5 Sr 0.5 MnO 3 ) precursor solution;

[0046] B. Preparation of composite magnetoelectric thin film

[0047] First, the (001) PMN-PT substrate was baked on a hot stage at 400°C for 25 minutes to reduce the stress on its surface. Using a homogenizer, drop the prepared LRMO precursor solution onto the cleaned (001) PMN-PT single crystal substrate rotating at a high speed at a constant speed. The speed of the substrate is first 500rpm for 9s, then 3500rpm for 30s , to obtain a layer of lanthanum strontium manganese oxide gel film; placed in a rapid annealing fu...

Embodiment 3

[0049] A. Preparation of precursor solution

[0050] Weigh 0.0036mol of lanthanum nitrate, 0.0084mol of strontium acetate and 0.012mol of manganese chloride, add 30mL of glacial acetic acid, heat to reflux to dissolve the solute completely, and obtain a transparent yellow solution; let it stand for 2 days, filter it with a 0.22μm microporous Membrane filtration can obtain stable lanthanum strontium manganese oxide (La 0.3 Sr 0.7 MnO 3 ) precursor solution;

[0051] B. Preparation of composite magnetoelectric thin film

[0052] Firstly, the (001) PMN-PT substrate was baked on a hot stage at 400°C for 40 minutes to reduce the stress on its surface. Using a homogenizer, drop the prepared LRMO precursor solution onto the cleaned (001) PMN-PT single crystal substrate rotating at a high speed at a constant speed. The speed of the substrate is first 400rpm for 5s, then 3000rpm for 20s , to obtain a layer of lanthanum strontium manganese oxide gel film; place it in a rapid anneal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com