Powder core wire for preparing Al-Ni-Nb-Co amorphous coating through high-speed electric arc spraying technology

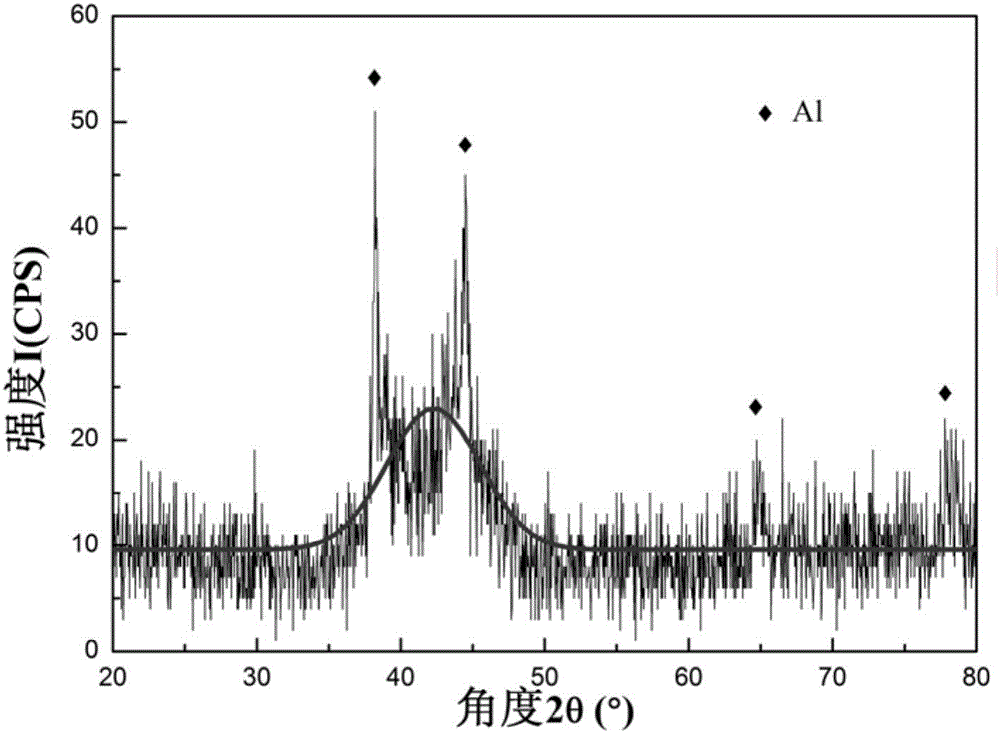

A technology of powder core wire material and arc spraying, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problem of failure to give full play to the performance characteristics of amorphous alloy materials, inconvenient theoretical research and optimization adjustment, Problems such as high crystal content, to achieve the effect of improving the comprehensive performance of anti-corrosion and wear resistance, low production cost, and high amorphous content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of powder core wire material and preparation method thereof for the preparation of Al-Ni-Nb-Co amorphous coating by high-velocity arc spraying technology

[0025] Select a 10×0.4 (width 10mm, thickness 0.4mm) pure aluminum strip, first roll it into a U shape, according to the mass percentage of each element of the powder core wire material: 12% Ni, 16% Nb, 6% Co, Weigh the ingredients, put the obtained powder into the powder mixer and mix it for 1 hour, then add it into the U-shaped aluminum tape groove, the filling rate is 34%, then close the U-shaped aluminum tape groove to coat the powder, and then After multi-channel drawing and reduction to a diameter of 2.0mm, the finished powder core wire is wound into a disc shape required for delivery, and it is measured and packaged to form a ready-to-deliver product.

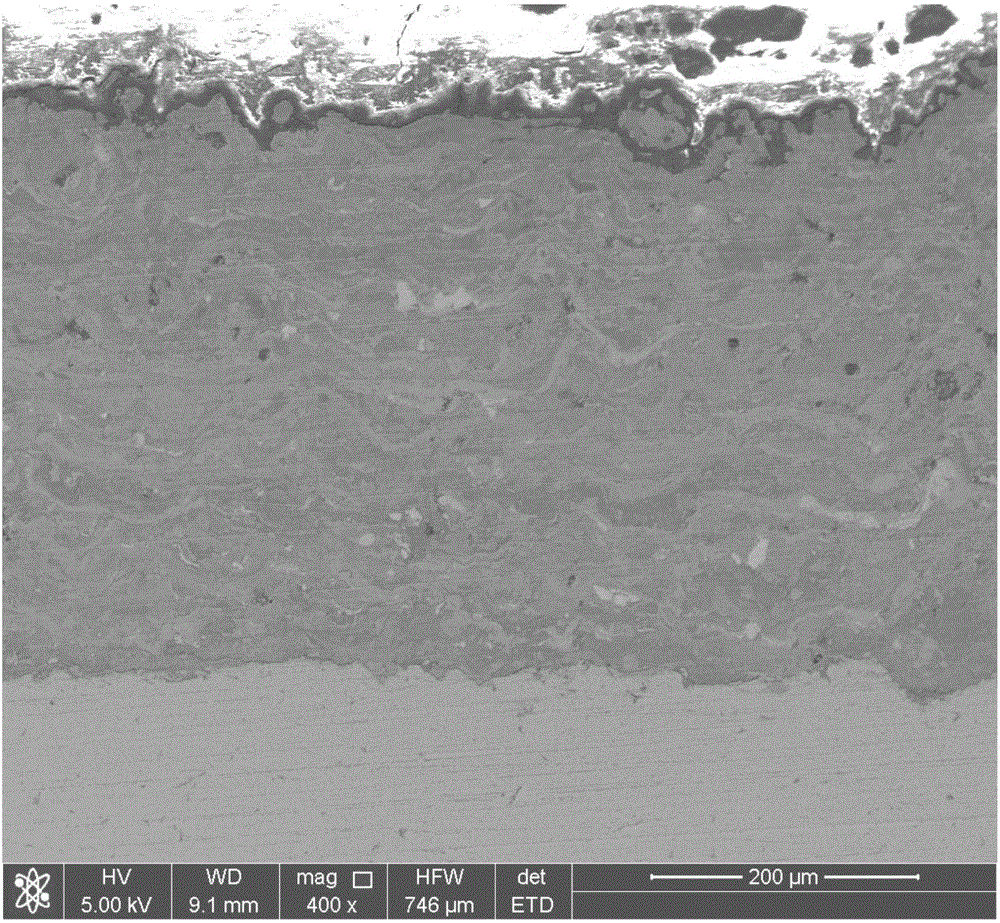

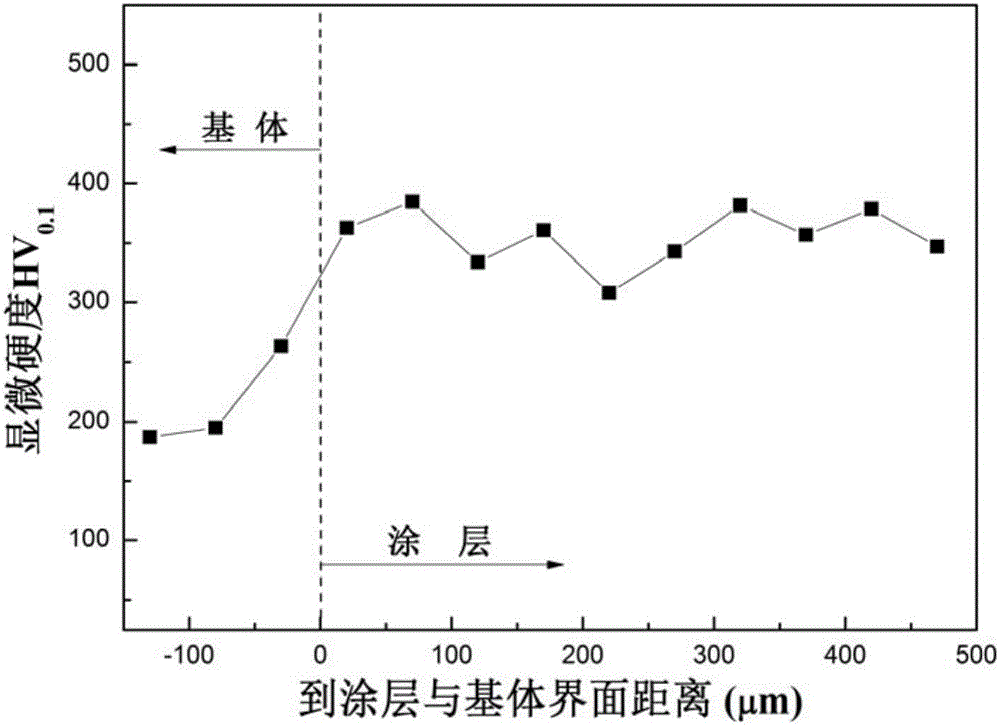

[0026] With the powder core wire material prepared in Example 1 as material, the spraying process parameters used for preparing the amorph...

Embodiment 2

[0028] Embodiment 2: A kind of powder core wire material and preparation method thereof for the preparation of Al-Ni-Nb-Co amorphous coating by high-velocity arc spraying technology

[0029] Select a 10×0.4 (width 10mm, thickness 0.4mm) pure aluminum strip, first roll it into a U shape, according to the mass percentage of each element of the powder core wire material: 16% Ni, 12% Nb, 8% Co, Weigh the ingredients, put the obtained powder into the powder mixer and mix it for 1 hour, then add it into the U-shaped aluminum tape groove, the filling rate is 36%, then close the U-shaped aluminum tape groove to coat the powder, and then After multi-channel drawing and reduction to a diameter of 2.0mm, the finished powder core wire is wound into a disc shape required for delivery, and it is measured and packaged to form a ready-to-deliver product.

[0030] With the powder core wire material prepared in Example 2 as the material, the spraying process parameters used to prepare the alumi...

Embodiment 3

[0032] Embodiment 3: A kind of powder core wire material and preparation method thereof for the preparation of Al-Ni-Nb-Co amorphous coating by high-velocity arc spraying technology

[0033] Select a 10×0.4 (width 10mm, thickness 0.4mm) pure aluminum strip, first roll it into a U shape, according to the mass percentage of each element of the powder core wire material: 14% Ni, 14% Nb, 10% Co, Weigh the ingredients, put the obtained powder into the powder mixer and mix it for 1 hour, then add it into the U-shaped aluminum tape groove, the filling rate is 38%, then close the U-shaped aluminum tape groove to coat the powder, and then After multi-channel drawing and reduction to a diameter of 2.0mm, the finished powder core wire is wound into a disc shape required for delivery, and it is measured and packaged to form a ready-to-deliver product.

[0034] With the powder core wire material prepared in Example 3 as the material, the spraying process parameters used to prepare the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com