Sensing elastic foam and multi-channel coaxial extrusion additive manufacturing equipment and method thereof

An elastic foam, additive manufacturing technology, applied in manufacturing, additive processing, liquid material additive processing, etc., can solve problems such as difficulty in meeting user personalized customization requirements, high production costs, waste of manpower, time and cost , to achieve the effect of saving manpower, fast forming speed and high degree of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

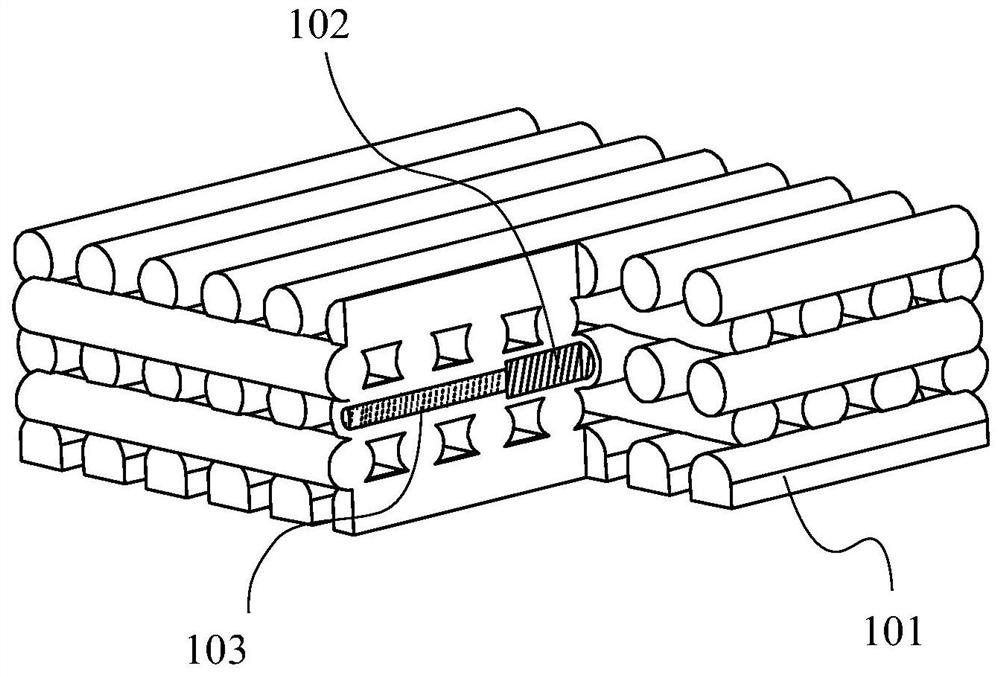

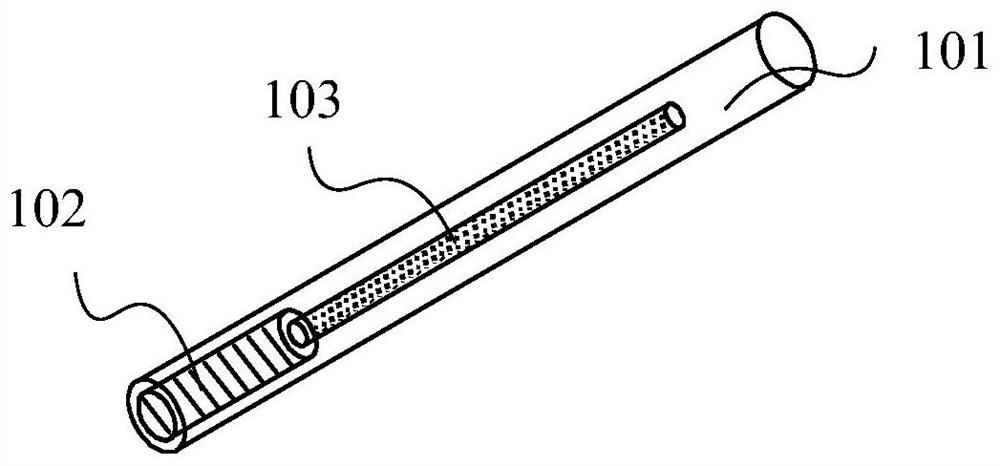

[0047] Such as figure 1 and 2 As shown, a sensing elastic foam, the sensing elastic foam 10 is an elastic dielectric unit, which is formed by stacking no less than three layers of porous grids, and each layer of porous grids is formed by interweaving core-shell line structural units , the core-shell line structure unit includes an elastic line unit 101, a sensing unit 102 and a wire unit 103, wherein the sensing unit 102 and the wire unit 103 are cores, the elastic line unit 101 is a shell, and the sensing unit 102 is in The resistance, capacitance or inductance change significantly after being subjected to force deformation, heat or other external stimuli, and the resistance and the change of the wire unit 103 are smaller than the sensing unit 102, so the elastic foam can realize the sensing function.

[0048] The line width of the elastic line unit 101 is 1100 microns, and the wall thickness is 1100 microns; the line width of the sensing unit 102 is 1100 microns, the wall t...

Embodiment 2

[0071] A sensing elastic foam, the sensing elastic foam 10 is an elastic dielectric unit formed by stacking no less than three layers of porous grids, each layer of porous grids is formed by interweaving core-shell line structural units, the The core-shell line structure unit includes an elastic line unit 101, a sensing unit 102 and a wire unit 103, wherein the sensing unit 102 and the wire unit 103 are cores, the elastic line unit 101 is a shell, and the sensing unit 102 deforms under force. , heat or other external stimuli, the resistance, capacitance or inductance change obviously, and the resistance and the change of the wire unit 103 are smaller than the sensing unit 102, so the elastic foam can realize the sensing function.

[0072] The line width of the elastic line unit 101 is 1200 microns, and the wall thickness is 1200 microns; the line width of the sensing unit 102 is 1200 microns, the wall thickness is 300 microns, and the inner diameter of the inner core is 600 mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com