Quenching apparatus and method of red coke in coking industry

A technology for quenching coke and coke, applied in the fields of energy and energy recycling and environmental protection, can solve the problems of high equipment investment and operation cost, restricting the widespread popularization of CDQ technology, and heavy cost burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

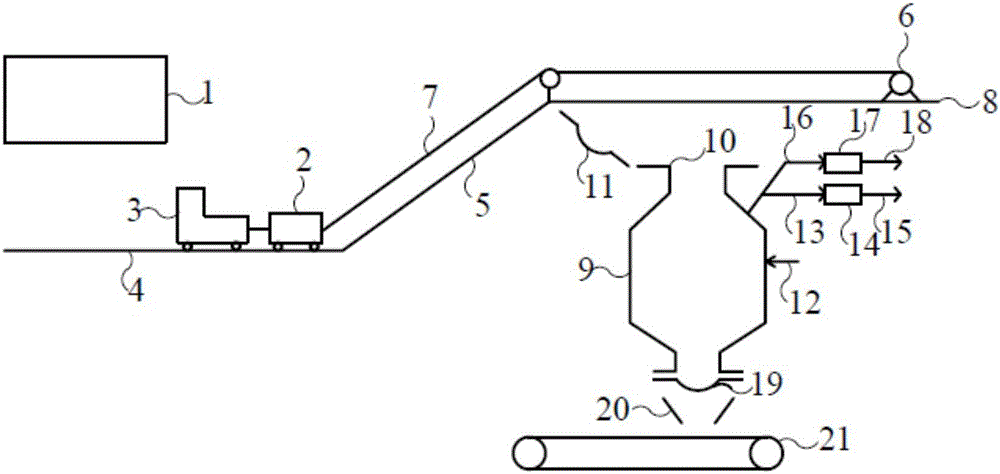

[0051] This embodiment is a coke quenching process plan for red coke with water spray vaporization and cooling in a closed system. The system is as follows figure 1 shown. The red coke pushed out from the carbonization chamber of the coke oven 1 is loaded into the red coke trough 2, and then moved by the moving vehicle 3 from the horizontal track 4 under the coke oven to the entrance of the inclined track 5 to leave the moving vehicle and connect with the cable of the hoist 6. 7 is connected, rises to the coke quenching tank top track 8 under its drive, and moves to the top of the coke quenching tank 9, and has completed the coke transportation process. Then from the red coke tank, the red coke is passed through the coke charging funnel (not shown in the figure) to the quenching tank (the coke discharge port at the bottom of the quenching tank has been sealed by the coke discharge port cover 19) through the quenching tank red coke inlet 10 ) into coke. After the coke loading...

Embodiment 2

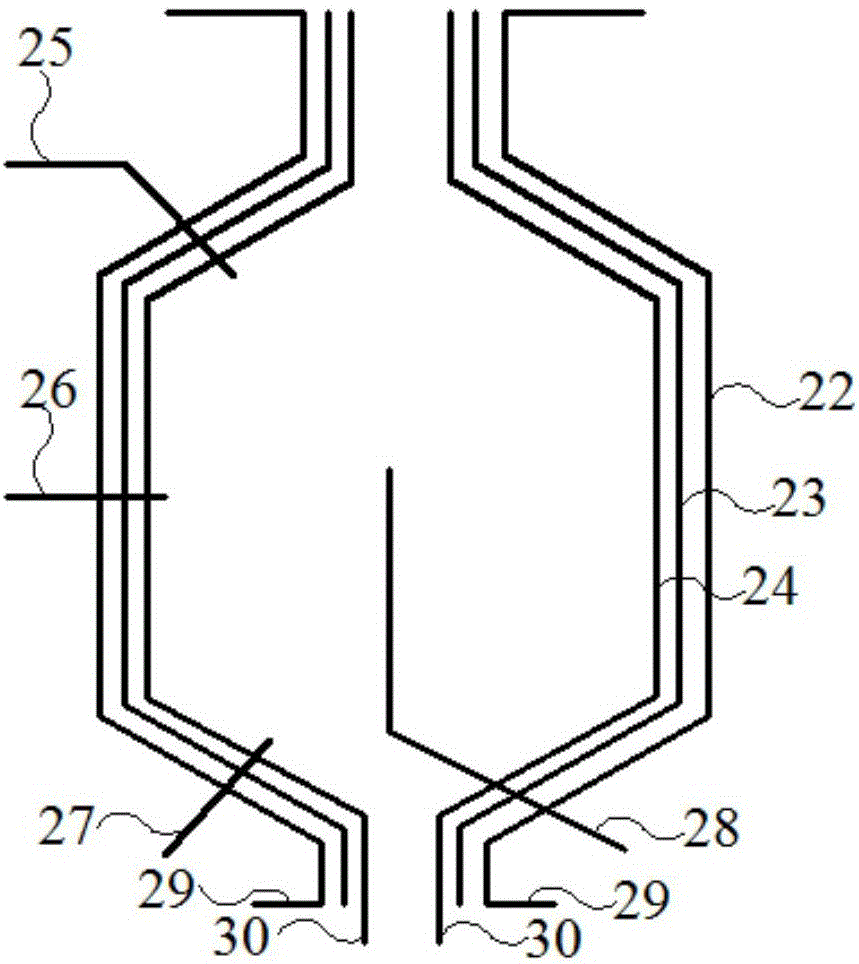

[0059] This embodiment is basically the same as Embodiment 1, except that the coke transportation process is that the red coke trough carrying the red coke pushed out from the coking chamber of the coke oven is moved from the horizontal track under the coke oven to the quenching tank by a moving vehicle After that, the hoist lifts the red coke tank to the top of the quenching tank for coke loading. The process of coke loading is to move the red coke tank directly to the top of the quenching tank to connect with the red coke loading port on the top of the quenching tank, and then open the bottom gate of the red coke tank to directly put red coke into the quenching tank. Water spraying to red coke adopts top water spray pipe 25 to spray water in the tank for 6 seconds and then closes the top water spray pipe, and uses middle water spray pipe 26 and bottom water spray pipe 27 of the same side from one side to spray water from all around , then spray water from the central water s...

Embodiment 3

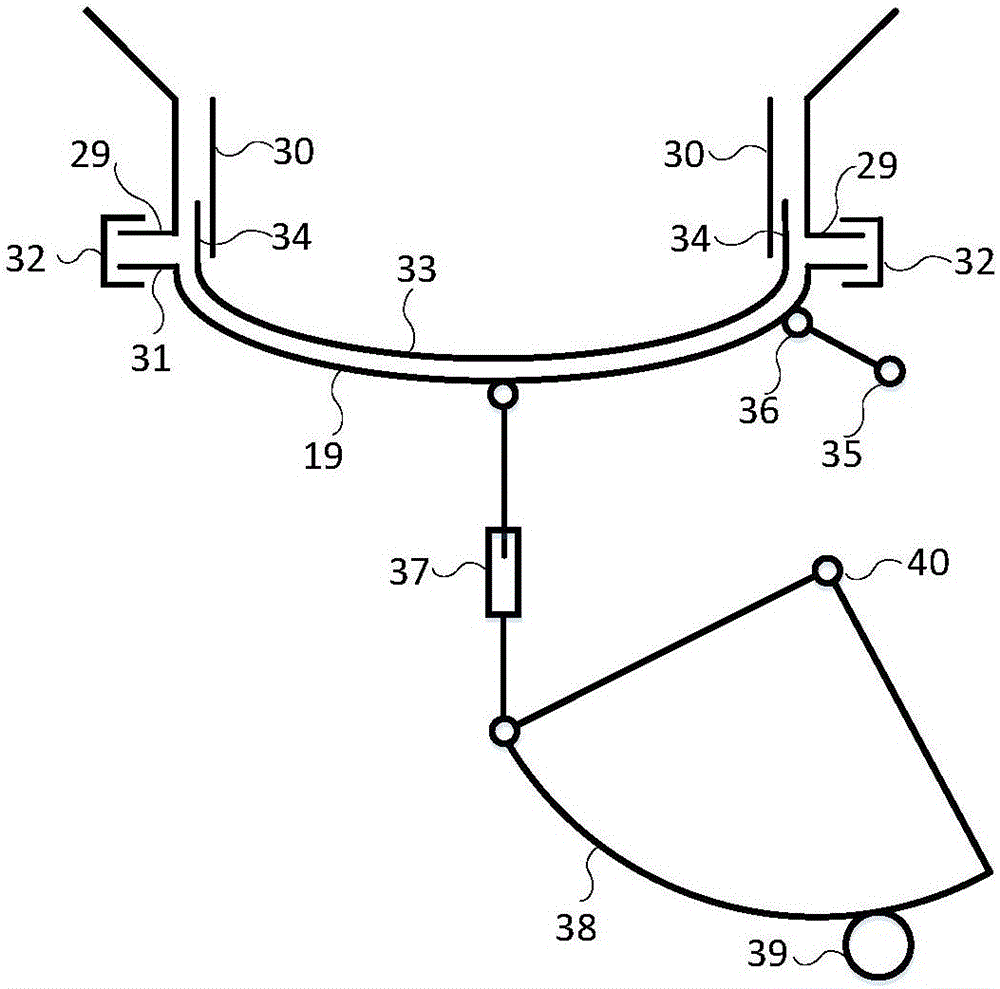

[0066] This embodiment is basically the same as Embodiment 1, the difference is that the rotary drive mechanism for opening and closing the lid of the coke discharge port is driven by a hydraulic cylinder 37 for opening and closing the lid of the coke discharge port to rotate around the lid of the coke discharge port to drive the support point of the single-rod hydraulic mechanism 57 rotate to open and close the lid of the coke discharge port, such as Figure 10 shown. The locking of the coke discharge port flange and its tank cover flange adopts the turn plate method that can embed the coke discharge port flange and the coke discharge port tank cover flange through reciprocating movement from both radial sides of the coke discharge port flange. Blue locking structure. When the coke discharge port is airtight, the coke discharge port flange locking ring plate 63 is closed from both sides of the coke discharge port flange radially, and the coke discharge port flange and its ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com