Glass adhesive and preparation method thereof

An adhesive and glass technology, applied in the directions of adhesives, adhesive additives, adhesive types, etc., can solve the problems of poor waterproof effect of adhesives, long solidification process time, poor adhesiveness of adhesives, etc. Good staying power, good waterproof effect, not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

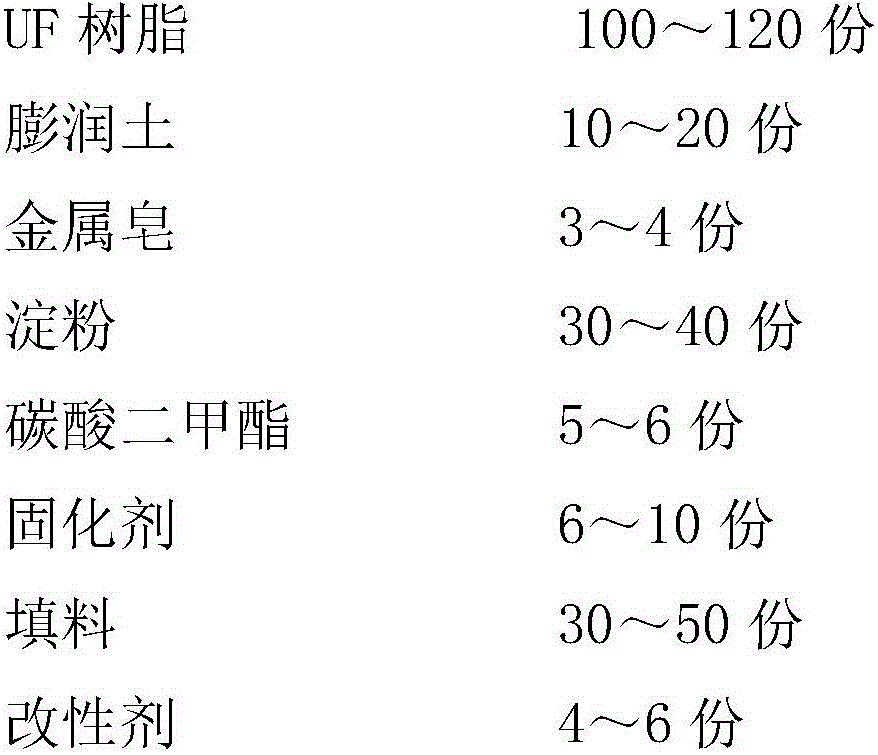

[0026] A glass adhesive, comprising the following raw material components in parts by weight:

[0027]

[0028] The curing agent comprises, by weight, 2 parts of phoxim, 5 parts of tartaric acid and 1 part of hexamethylenetetramine.

[0029] The filler comprises, by weight, 5 parts of wood powder, 2 parts of shell powder and 2 parts of heavy calcium carbonate powder.

[0030] The modifying agent comprises, by weight, 1 part of tannin extract, 3 parts of gelatin and 1 part of quercetin.

[0031] A preparation method for glass adhesive, comprising the following steps,

[0032] 1) Add UF resin, bentonite, metal soap, dimethyl carbonate and water to the mixer in turn to fully stir and adjust the glue;

[0033] 2) Add starch and filler and stir until there is no air mass in the raw material of the mixer;

[0034] 3) Add curing agent and stir under vacuum for 5-10 minutes, then let stand for 15 minutes;

[0035] 4) Finally, add the modifying agent and stir.

[0036] In the p...

Embodiment 2

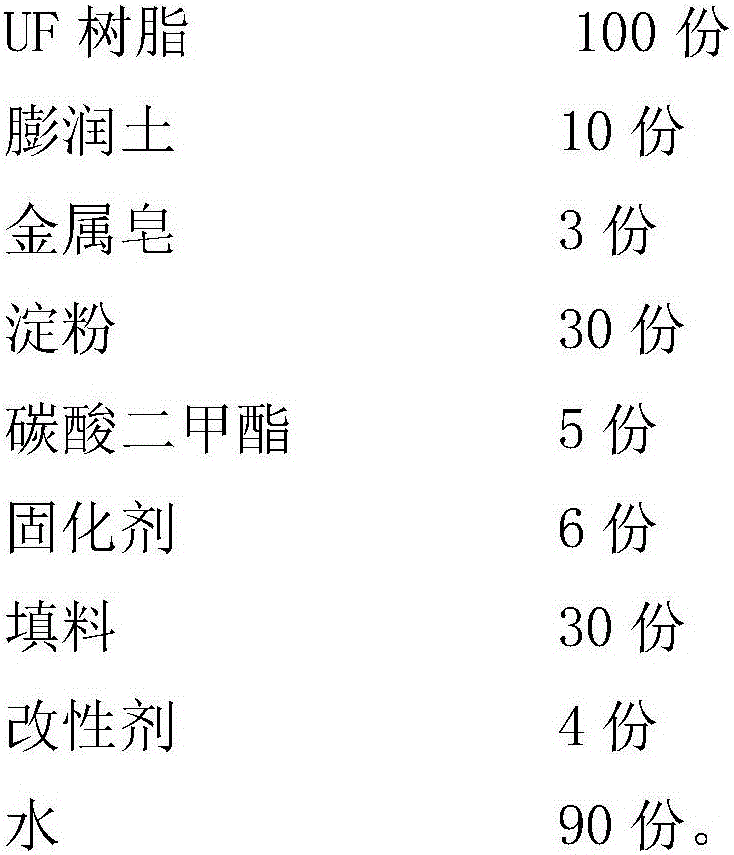

[0039] A glass adhesive, comprising the following raw material components in parts by weight:

[0040]

[0041]

[0042] The curing agent comprises, by weight, 2.53 parts of phoxim, 6 parts of tartaric acid and 1.5 parts of hexamethylenetetramine.

[0043] The filler comprises, by weight, 6 parts of wood powder, 3 parts of shell powder and 3 parts of heavy calcium carbonate powder.

[0044] The modifying agent comprises, by weight, 2 parts of tannin extract, 5 parts of gelatin and 1.5 parts of quercetin.

[0045] A preparation method for glass adhesive, comprising the following steps,

[0046] 1) Add UF resin, bentonite, metal soap, dimethyl carbonate and water to the mixer in turn to fully stir and adjust the glue;

[0047] 2) Add starch and filler and stir until there is no air mass in the raw material of the mixer;

[0048] 3) Add curing agent and stir under vacuum for 5-10 minutes, then let stand for 15 minutes;

[0049] 4) Finally, add the modifying agent and st...

Embodiment 3

[0053] A glass adhesive, comprising the following raw material components in parts by weight:

[0054]

[0055] The curing agent comprises, by weight, 3 parts of phoxim, 7 parts of tartaric acid and 2 parts of hexamethylenetetramine.

[0056] The filler comprises, by weight, 8 parts of wood flour, 4 parts of shell powder and 4 parts of heavy calcium carbonate powder.

[0057] The modifying agent comprises, by weight, 3 parts of tannin extract, 8 parts of gelatin and 2 parts of quercetin.

[0058] A preparation method for glass adhesive, comprising the following steps,

[0059] 1) Add UF resin, bentonite, metal soap, dimethyl carbonate and water to the mixer in turn to fully stir and adjust the glue;

[0060] 2) Add starch and filler and stir until there is no air mass in the raw material of the mixer;

[0061] 3) Add curing agent and stir under vacuum for 5-10 minutes, then let stand for 15 minutes;

[0062] 4) Finally, add the modifying agent and stir.

[0063] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com