Master batch with photoconversion function

A photoconversion and functional technology, applied in the field of masterbatch with photoconversion function, can solve the problems of small distinction, inability to bring substantial changes, and unmentioned dosage, etc. Thermal insulation performance, no chemical pesticide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

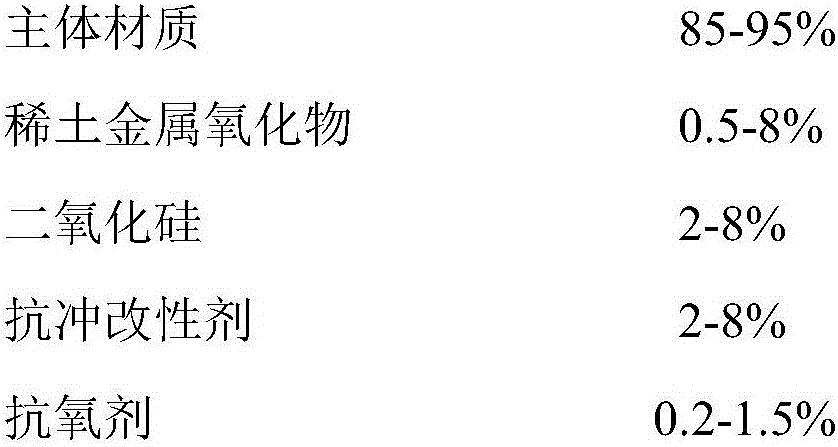

[0022] A masterbatch with light conversion function, made of the following raw materials in weight percentage:

[0023]

[0024] The main body material is LDPE.

[0025] The rare earth metal oxide is cerium oxide.

[0026] The particle size of the rare earth metal oxide is 800 mesh.

[0027] The impact modifier is microcrystalline wax.

[0028] Described antioxidant is B215.

[0029] The usage amount of the masterbatch with light conversion function is 2% of the film mass.

[0030] After preparing the masterbatch, mix LDPE, LLDPE, mLLDPE and the masterbatch. After mixing, extrude and blow the film through the extruder, and then draw and roll after being cooled by the air ring to obtain the finished product.

Embodiment 2

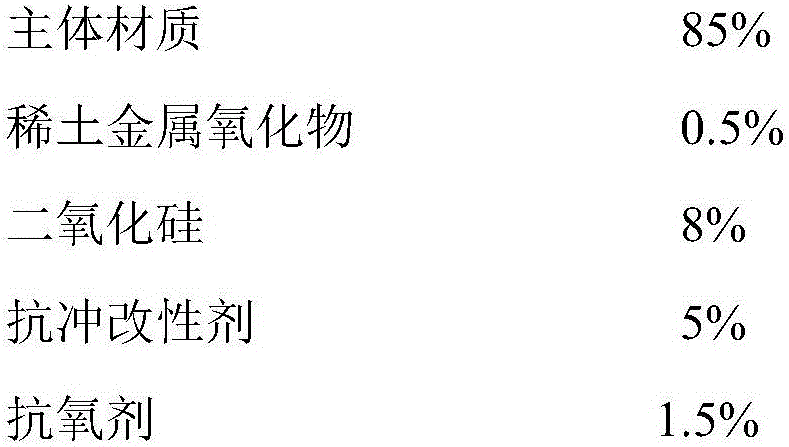

[0032] A masterbatch with light conversion function, made of the following raw materials in weight percentage:

[0033]

[0034] The main material is mLDPE and POE mixed according to the mass ratio of 1:1.

[0035] The rare earth metal oxide is a mixture of cerium oxide and neodymium oxide in a mass ratio of 1:2.

[0036] The particle size of the rare earth metal oxide is 2500 mesh.

[0037] The impact modifier is a mixture of microcrystalline wax, polyethylene wax and EVA wax in a mass ratio of 1:1:1.

[0038] Described antioxidant is 225.

[0039] The amount of the masterbatch with light conversion function is 10% of the mass of the film.

[0040] After preparing the masterbatch, mix LDPE, LLDPE, mLLDPE and the masterbatch. After mixing, extrude and blow the film through the extruder, and then draw and roll after being cooled by the air ring to obtain the finished product.

Embodiment 3

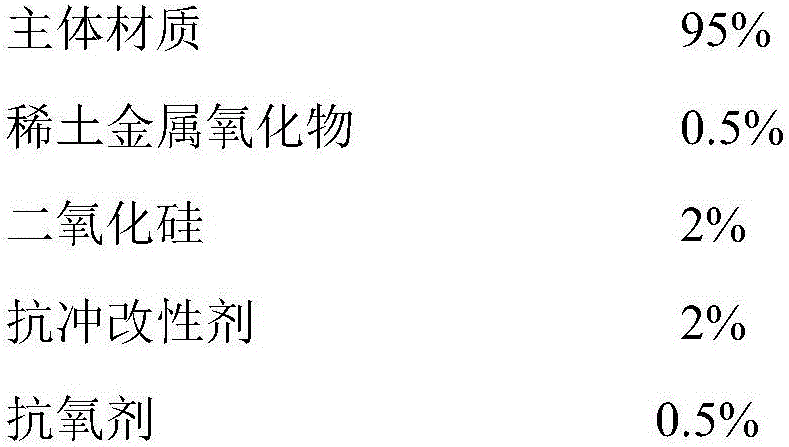

[0042] A kind of described masterbatch with photoconversion function is made of the following raw materials in weight percentage:

[0043]

[0044] The main body material is POE.

[0045] The rare earth metal oxide is yttrium oxide.

[0046] The particle size of the rare earth metal oxide is 1000 mesh.

[0047] The impact modifier is EVA wax.

[0048] Described antioxidant is B215.

[0049] The amount of the masterbatch with photoconversion function is 70% of the mass of the film.

[0050] After preparing the masterbatch, mix LDPE, LLDPE, mLLDPE and the masterbatch. After mixing, extrude and blow the film through the extruder, and then draw and roll after being cooled by the air ring to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com